LUMATEQ LT848-20-110-00 User Manual

Instructions, Safety instructions

LUMATEQ is a division of TACO Metals, Inc.

To view the entire portfolio of LUMATEQ products and for Warranty and Product Information, go to lumateq.com

Corporate Headquarters 50 NE 179 Street, Miami, FL 33162 • 305.770.2392 • Fax: 305.653.8569 ©2014 All Rights Reserved

INSTRUCTIONS

Tube Lamp (LT848-20-110-00)

Safety Instructions:

This product must be installed in accordance with the applicable installation code

by a person familiar with the construction and operation of the product and the

hazards involved.

Risk of fire or electrical shock with the following:

•

The Electrical rating of these products is 100V-277V AC. Determine if there is 100V-277V at the

luminaries before installation.

•

Reflector kit installation requires knowledge of electrical systems for fluorescent lighting luminaries.

If not qualified, do not attempt installation. Contact a qualified electrician.

•

Install this kit only in the luminaries that has the construction features and dimensions shown in the

photographs and / or drawings.

•

To prevent wiring damage or abrasion, do not expose wiring to edges of sheet or other sharp objects.

Do not make or alter any open holes in an enclosure of wiring or electrical components

during kit installation.

The retrofit assembly is accepted as a component of a fluorescent recessed luminaire. The

suitability of the combination will be determined by CSA or authorities having jurisdiction.

•

For use only with ETL, UL and C-UL Listed Surface or type IC or NON - IC Recessed Mount Fluorescent

Luminaries with or without diffuser.

•

Since the original light fixture has been modified with retrofit luminary, it can no longer operate as the

original intended lamp.

•

Suitable for dry and damp locations.

•

Has been evaluated for use with ceiling fixtures and suitable for use in totally enclosed recessed fixture.

Do not use with dimmers.

This device is not intended for use with emergency exits.

WARNING

Addendum:

LUMATEQ equipment that is directly connected to AC mains (e.g. 120/220/277VAC) can be damaged by short circuit and overload

conditions. In addition, lightning surges or load switching transients (originating outside the bulb) can create voltage spikes or ring waves

that can stress and ultimately damage components and render the fixture inoperable. Given that the value proposition for LED bulbs is

not only lower energy usage, but longer lifetimes, it will be crucial that transient voltage protection is taken into account to eliminate field

failures driven by the electrical environment.

Ensure the following steps are taken to decrease the chance of damage from short circuits and overload conditions:

1. Do not use mechanical timers or contactors to switch on the lamp. These contacts are known

to produce voltage spikes which are detrimental to the circuitry of the lamp.

It is recommended to use a solid state relay to provide power to the fixture.

2. Replace old circuit breakers, as corroded contacts on both the bus bar and internal contacts

of the breaker can cause destructive electrical spikes.

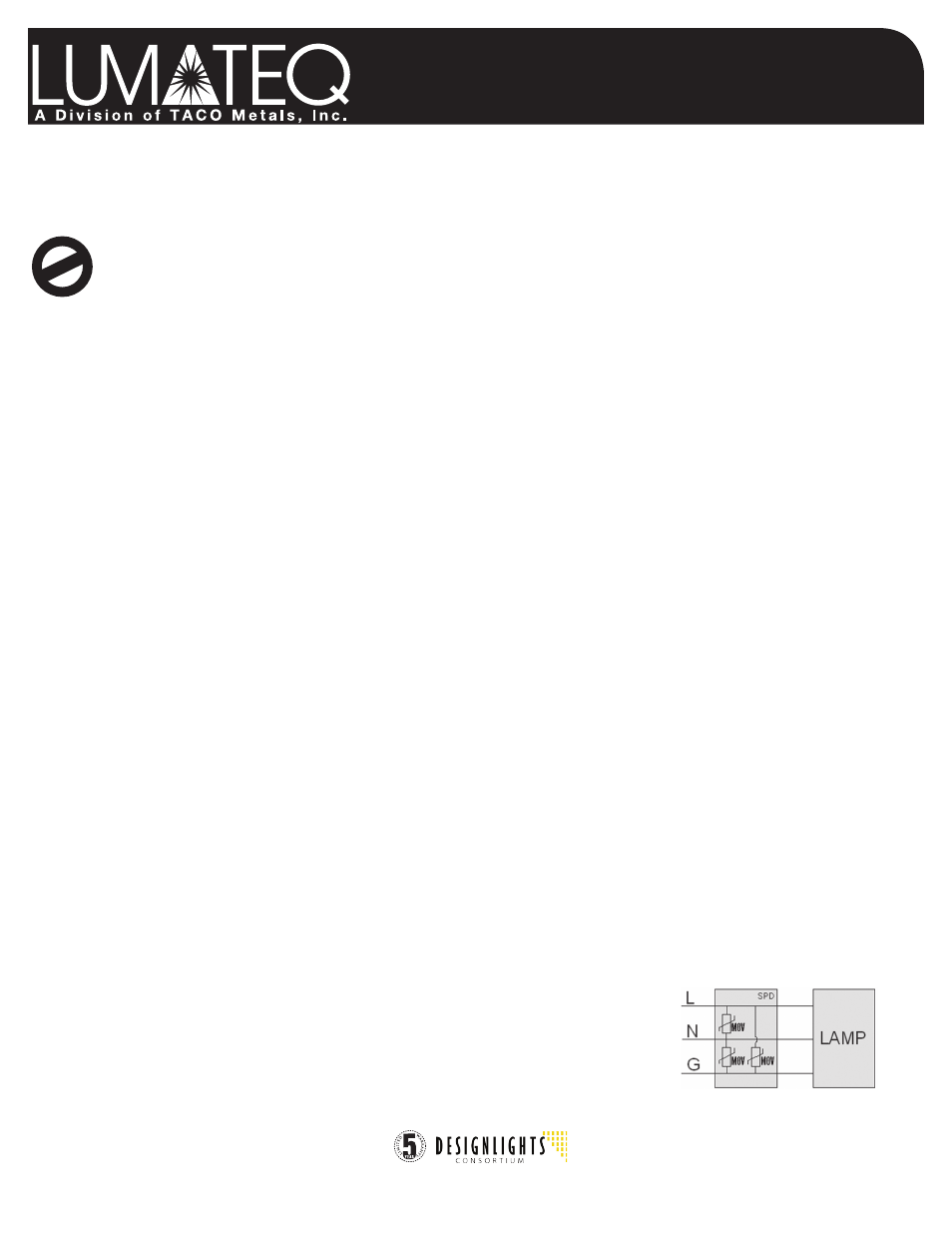

3. Use a surge protection device (SPD) spanning both Line, Neutral and Ground.

These devices contain MOV’s (a metal oxide varistor) which can help protect the LED bulb from

overvoltage surges and ring-wave effects by clamping short-duration voltage impulses as shown in drawing.