UEi Test Instruments KM900PLUS User Manual

Page 28

KANE900 Plus Operators Manual

Page 27

10. PROBLEM

SOLVING

The following is a list of problems that may occur on the instrument through its

operating life. If the cause of the fault is not easy to identify then we advise you

contact Kane International Service Department or an International Distributor for

expert advice.

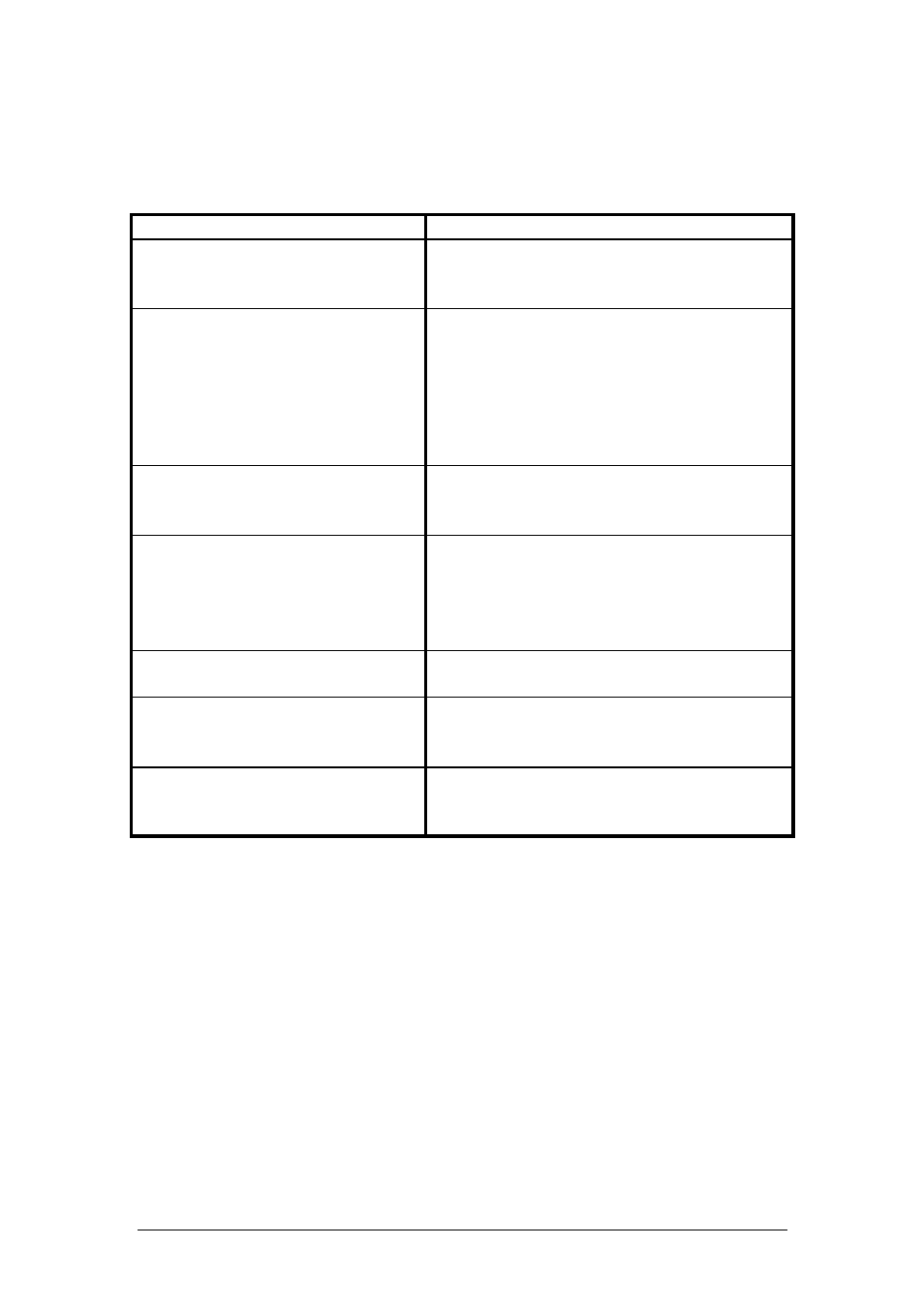

Fault symptom

Causes

• Oxygen too high

• CO

2

too low

• Air leaking into probe, tubing, water trap,

connectors or internal to instrument.

• Oxygen cell needs replacing.

• Oxygen Error (FAULT)

• Toxic sensor Error (FAULT)

• Calibration time set too short and

instrument not allowed to stabilise

• Instrument has been stored in a cold

environment and is not at normal working

temperature.

• Oxygen cell or toxic sensors needs

replacing.

• Analyser not holding charge

• Analyser not charging

• Battery exhausted.

• AC charger not giving correct output.

• Fuse blown in charger plug.

• Analyser does not respond to flue

gas

• Particle filter blocked.

• Probe or tubing blocked.

• Pump not working or damaged with

contaminants.

• Probe connected to pressure connector.

• Flue temperature readings erratic • Temperature plug reversed in socket.

• Faulty connection or break in cable or plug.

• Analyser automatically switches

off in operation.

• Battery below alarm level.

• Ambient temperature above 50°C.

• Battery quickly discharging and is faulty.

• Display shows dark lines and no

response from ON/OFF key.

• Fault has occurred on the instrument

electronics and requires resetting. Contact

Kane International or Distributor.

11. ANNUAL

RE-CALIBRATION

Whilst the sensors have an expected life of more than two years in normal use it is

recommended that the analyser is re-calibrated at least annually. This is so that long

term drift on the sensors and electronics can be eliminated. Local regulation may

require more frequent re-calibration and users should check with appropriate

authorities to ensure they comply with relevant guidelines.