UEi Test Instruments RLD10` User Manual

Page 4

Disassembly of Sensor

1. Turn the instrument’s power off. Mild electrical shock may result if

you make contact with the sensor while power is on.

2. Remove the tip guard from the metal tip housing by twisting it

clockwise while away from the Gooseneck.

3. Remove the metal tip housing from the Gooseneck by holding the

Gooseneck steady while turning the tip housing counterclockwise.

• The base contact assembly may adhere to the tip housing as it

comes out. If so, the tip housing will tend to spring-back

clockwise with every counterclockwise turn.

• Continue turning as described until the metal housing can be

lifted away from the wand. You may have to hold it in place

after each turn.

• Pull the housing up just far enough to view the insulation on the

white plastic base contact.

• Grip the exposed white insulation with needle-nosed pliers,

holding it firm with the Gooseneck.

• Separate the metal housing away from the Gooseneck.

4. The sensor tip will commonly remain in the metal housing, and

must be forced out from the top (toward the Gooseneck end) with

a toothpick or similar instrument.

Replace or clean the sensor as desired then reassemble in reverse order.

Proper function depends on the unit’s electrical contacts. Make sure the

tip assembly is making good contact with the base and there is good

metal-to-metal contact on the tip housing-to-Gooseneck connection.

Calibration

When properly maintained, your instrument is sensitive to refrigerant

leaks as small as .4 ounces per year. To ensure your instrument is

performing at its peak, send it to the UEi factory or a qualified

instrument calibration facility for annual certification.

Battery Replacement

Always use a fresh replacement battery of the specified size and type.

Immediately remove the old or weak battery from the meter and

dispose of it in accordance with your local disposal regulations. Batteries

can leak chemicals that corrode electronic circuits. If your meter is not

going to be used for a month or more, remove and store the battery in

a place that will not allow leakage to damage other materials.

Replace battery when:

• The green “READY” light begins to glow red

• No lights or other activity occurs upon turning the instrument on

• Tic rate quickly begins to increase when no refrigerant is

being detected*

*An increase in tic rate may be experienced if the unit remains on for a

long period. This is a normal response to decreasing battery life. Turn

the unit off and allow it to recalibrate in fresh air if this occurs.

To install a new battery, follow these procedures:

1. Remove the battery cover.

2. Remove the battery using a coin or screwdriver.

3. Replace the battery, observing indicated polarity.

Tro u b l e s h o o t i n g

This unit contains no user serviceable parts beyond those listed in the

table. In the event your instrument is physically damaged or does not

function properly after taking the listed action, please return the

instrument to UEi following the warranty and service instructions.

S p e c i f i c a t i o n s

Operating Conditions

To ensure accurate readings from your RLD10, use it only when ambient

air is within this range:

Temperature:

32 to 120˚F

Humidity:

0 to 80% RH (non condensing)

Gasses Detected

The RLD10 detects a wide variety of refrigerant. The following list

represents a portion of the refrigerant and gasses detected:

R11

R12

R13

R22

R23

R113

R114

R134A

R500

R502

Halons

R404A

SF6

Perchlorethylene

Blends

R410A

RLD10-MAN

P. 3

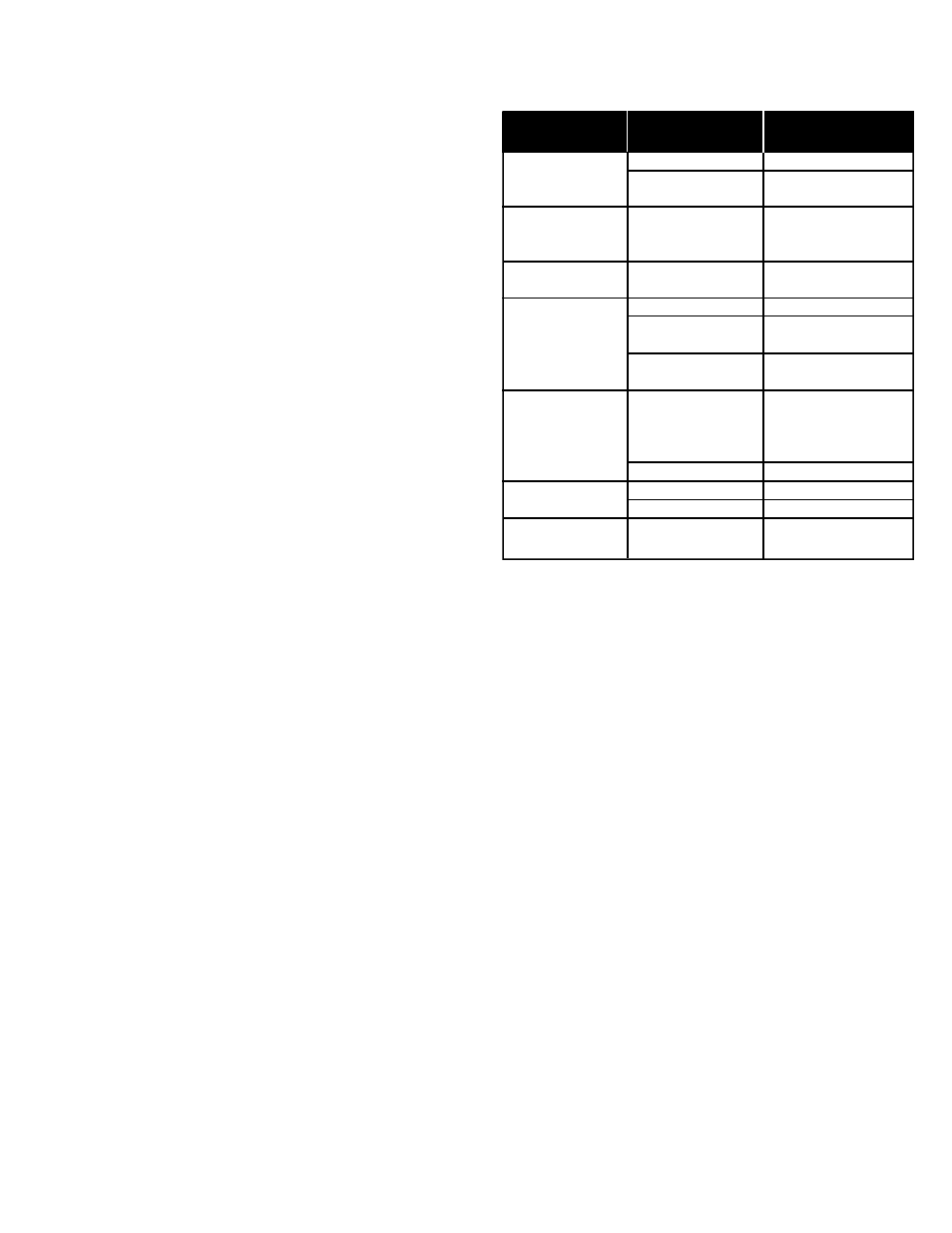

If I See This

Malfunction

Instrument does not

turn on

Instrument does not tic

after it is switched on,

but the lights work

Appropriate indicators

do not light

The tic rate does not

increase when the sen-

sor is exposed to

refrigerant or other

detectable gas

Tic rate increases

during use

Tic rate remains fast

after warm up

The green power-on

indicator appears red

I Should

Check For

Battery voltage

Mode switch position

Earphone jack

Battery voltage

Airflow to sensor

Sensor connection

Sensor contamination

Reduced battery voltage

Moisture in sensor cavity

Moisture in sensor cavity

Battery voltage

Battery voltage

Then Take This Corrective

Action

Replace low battery

Place firmly in Low or

High position

Remove earphone plug or

debris inserted in receptacle

Replace low battery

Clear restriction

Clean and tighten sensor

component contacts

Clean or replace sensor

Cycle off (5 seconds) and

back on (Recalibrates to

compensate for

decreasing voltage)

Disassemble and dry sensor

Disassemble and dry sensor

Replace low battery

Replace low battery