Sterlco SLS Series Light Duty Shredder User Manual

Page 30

GRN4-600

Chapter 5: Maintenance

30 of 50

Replacing lubricant

Renewing the lubricant between the specified intervals is only necessary when unusual

bearing noises or overheating occurs. Mounting and dismounting the bearings must be

performed according to the instruction in the operation manual.

Follow the steps below to replace the lubricant.

1. Open the bearing.

2. Remove the bearing housing and the bearing cover.

3. Carefully clean the bearing with petroleum ether. (Petroleum ether, petroleum,

spirit, aqueous neutral, or alkaline cleaning agents may be used to clean the

bearings.) The bearing must be immediately preserved with the lubricant after

cleaning in order to avoid corrosion.

4. Fill the bearing with an approved lubricant (see “list of lubricants”).

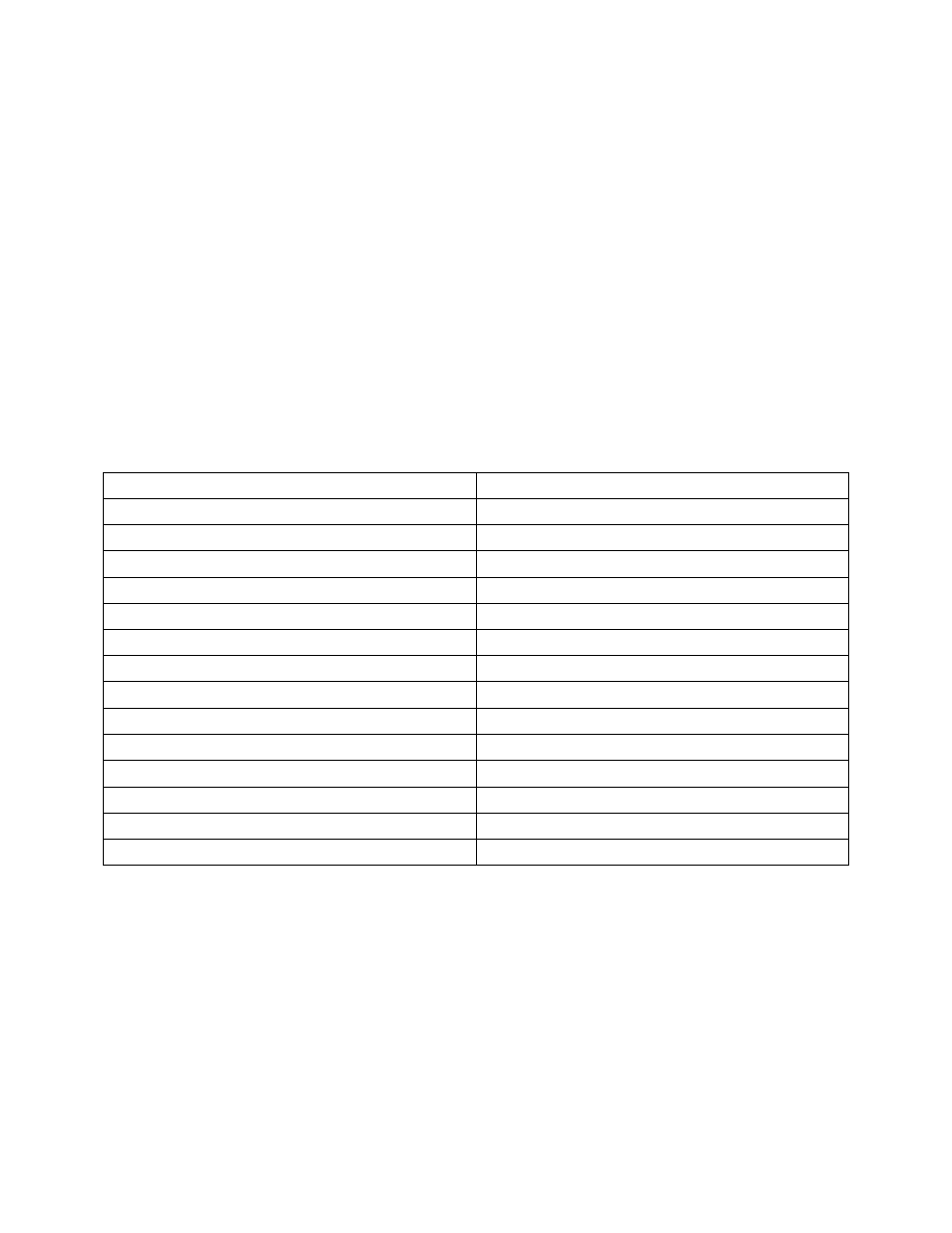

List of lubricants

Name/ Country of Manufacturer

Roller Bearing Grease

ARAL

ARAL Grease HL 3

BP

BP ENERGREASE LS 3

CASTROL

CASTROL SPHEEROL AP 3

ESSO

Beacon 3

FUCHS

FUCHS Grease 1200; FUCHS Grease FWA 220

SHELL

SHELL Alvania Grease 3

MOBIL-OIL

MOBILUX 3

WISURA

WISURA Liba L 3

Zeller & Gmelin

ZET GE Grease M 50

FAG

FAG L 71

ANTAR Petroles de l’Antantique

ROLEXA

Holland, Beverol

Beverol Multi-Purpose Grease

Italy, Agip

AGIP Grease 33 FD

Sweden, NYNAS

Nynas FI 3-42