Chapter 5: maintenance, 1 preventative maintenance schedule, 2 testing the interlock switch – Sterlco BP 1000 Series Beside the Press Granulators User Manual

Page 24

1000 Series Granulators

Chapter 5: Maintenance

24 of 45

Chapter 5: Maintenance

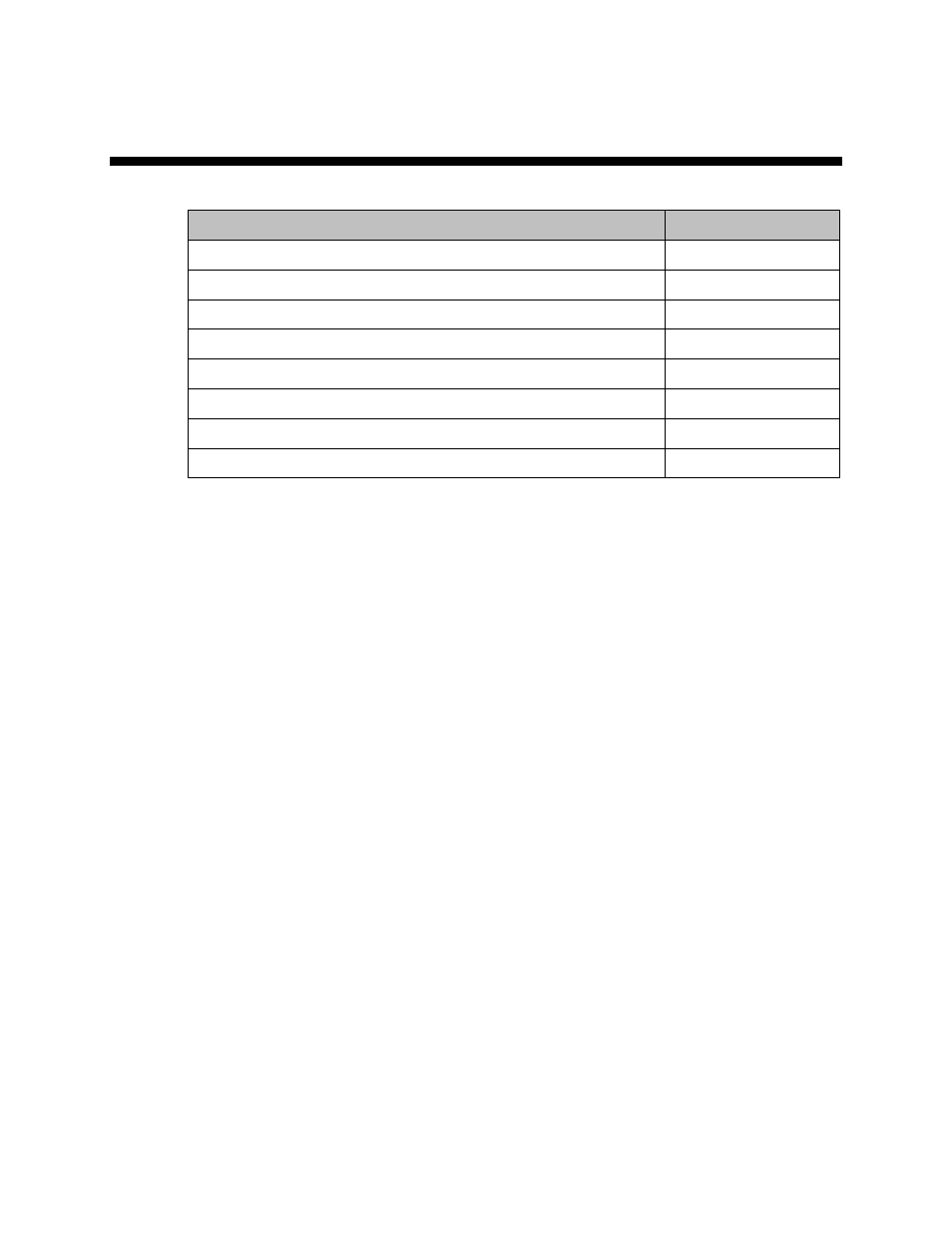

5-1 Preventative Maintenance Schedule

Check

Frequency

Knife clearance

Weekly

Knife retaining screws for tightness

Weekly

Shield retaining screws for tightness

Weekly

Screen cradle screws for tightness

Weekly

Lubrication of drive motor bearings

Monthly

Screen Wear

Monthly

Belt tension

Monthly

Hopper and cutting chamber screws are tight

Monthly

5-2 Testing the Interlock Switch

The cutting chamber interlock switch ensures that the granulator cannot be running when the

cutting chamber or screen cradle are open. When disengaged, the interlocks open the

electrical control circuit to the motor and prevent the machine from running.

To test the interlock switch, retract the interlock actuator screw by turning it

counterclockwise. Make sure that the end of the actuator screw is visible and clear of any

contact. The granulator should stop. If the granulator does not stop, the interlock is not

working. If the interlock does not work, the complete mechanism, including the switch, must

be removed and disassembled to determine the cause of the malfunction.