Sterlco BP800 Series Granulators User Manual

Page 34

800 Series beside-the-press

Chapter 6: Troubleshooting

34 of 43

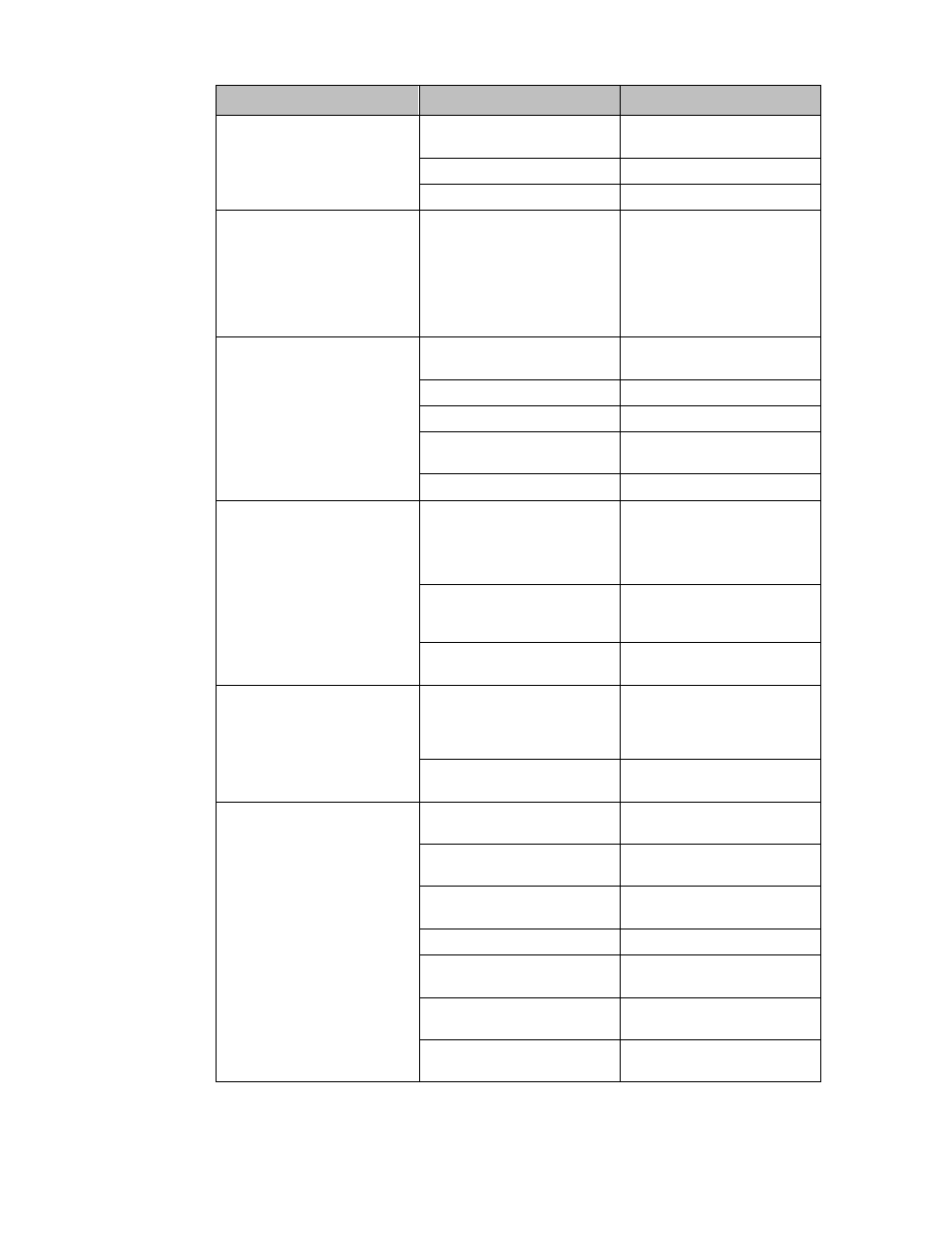

General Problems

Problem

Possible Cause

Possible Remedy

Overheating of bearings

Dirt or contamination in the

bearing

Correct source of

contamination

Excessive belt tension

Adjust belt tension

No lubrication

Check bearing seals

Knives moving in their seats

May be foreign matter on the

knives

Carefully clean seat

Knife screws loose

Tighten screws with torque

wrench at values specified

Knife screws weakened

Screws must not be used

more than 6 times

Broken Knife

Improper re-sharpening

Check knife grinding method

used

Extremely hard material

Contact supplier

Incorrect rotor direction

Check rotor direction

Foreign body in the cutting

chamber

Look for cause with operator

Faulty fitting of screen

Check assembly procedure

Excessive knife wear

Incorrect knife position

Correct the gap or distance

between bed knives and rotor

knives

Improper knife re-sharpening

Check dimensions with

figures included in this

manual.

Abrasive material

Contact the supplier for

special knives

Abnormal screen wear

Incorrect fitting of screen

Check that the screen is

correctly seated in its rear

position and that it fits

perfectly at the front

Abrasive material

Contact the supplier for

special knives

Rotor jamming

Excessive in-feed material

Reduce amount of material

being fed to the machine

Total or partial obstruction of

the screen holes

Remove the screen and clear

the holes

Insufficient belt tension

Check and/or adjust belt

tension

Knives worn

Replace with new knives

Distance between the knives

too small or large

Check distance between

knives

Screen holes too small

Increase screen hole

diameter

Failure of air conveying

system or discharge system

Check fan rotation and make

sure pipes are not obstructed