F-2000, 0 pipe installation requirements, 1 flow stream requirements – Blue-White F-2000 – Pipe Fittings User Manual

Page 4: 1 minimum pipe length requirements

!

To determine which type of flow exists in your installation, the following is required:

Flow rate of the fluid in GPM

= Q

Specific gravity of the fluid

= G

Pipe inside diameter in inches

= D

Fluid viscocity in centepoise

= V

Use the following equation to determine the REYNOLDS NUMBER:

REYNOLDS NUMBER

= 3160 x Q x G

D x V

Flow conditions with a Reynolds Number greater than 4000 is fully developed turbulent flow.

A Reynolds Number less than 2000 is laminar flow. The F-2000 requires a Reynolds number greater than 4000 to

maintain accuracy.

F-2000

Page 4

Fig. 2

! The F-2000 accuracy is based on steady, undisturbed flow with a fully developed turbulent flow profile.

Pulsating, swirling and other disruptions in the flow stream will effect the meters accuracy.

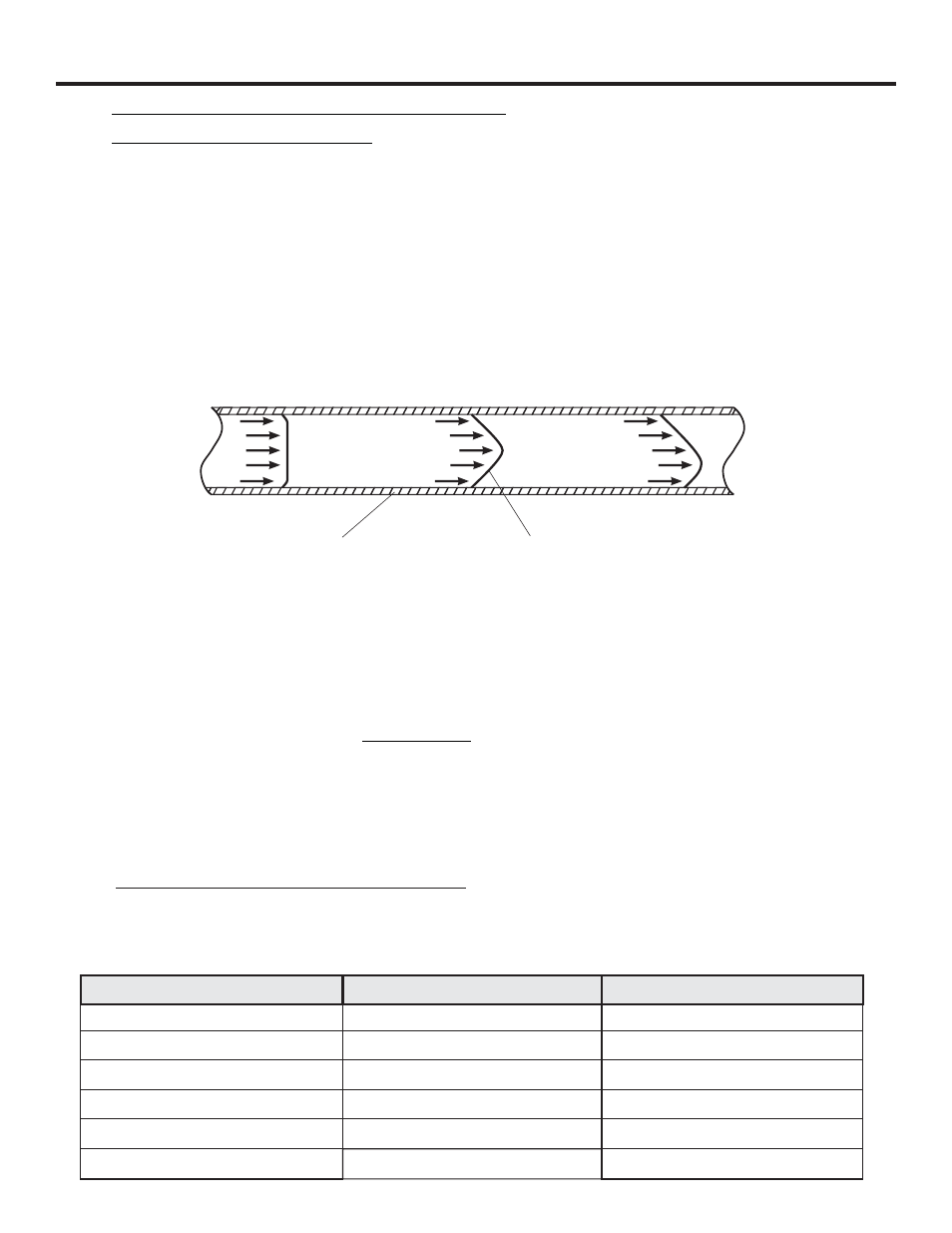

! There are two basic types of flow profiles; turbulent and laminar (see figure 2).

Turbulent flow exists when the speed of the fluid flowing in the pipe is nearly constant across the entire width of

the pipe. This is typical of low viscosity fluids like water, flowing at high velocity.

Laminar flow exists when the speed of the fluid flowing in the center of the pipe is greater than the speed of the

fluid at the outer edge near the pipe wall. This is typical of high viscosity fluids flowing at low velocity. Because

the F-2000 is measuring the fluid near the pipe wall only (especially in larger pipe sizes), a constant flow velocity

across the flow stream is required.

3.0

PIPE INSTALLATION REQUIREMENTS

3.1

Flow Stream Requirements

The F-2000 accuracy is affected by disturbances such as pumps, elbows, tees, valves in the flow stream.

Install the meter in a straight run of pipe as far as possible from any disturbances. The distance required for

accuracy will depend on the type of disturbance. (see figure 3 and 4).

3.1

Minimum Pipe Length Requirements

Type Of Disturbance

Minimum Inlet Pipe Length

Minimum Outlet Pipe Length

Flange

10 X Pipe Inside Diameter

5 X Pipe Inside Diameter

Reducer

15 X Pipe Inside Diameter

5 X Pipe Inside Diameter

o

20 X Pipe Inside Diameter

5 X Pipe Inside Diameter

90 Elbow

o

25 X Pipe Inside Diameter

5 X Pipe Inside Diameter

Two 90 Elbows -1 Direction

o

40 X Pipe Inside Diameter

5 X Pipe Inside Diameter

Two 90 Elbows -2 Directions

50 X Pipe Inside Diameter

5 X Pipe Inside Diameter

Pump Or Gate Valves

Pipe Cross Section

Flow Velocity Profile

Fully Developed

Turbulent Flow

Laminar

Flow

Disturbed Flow

(due to swirling)