C-1700n, Caution, 3 how to install the tubing and fittings – Blue-White C-1700N CHEM-FEED Diaphragm Pump User Manual

Page 6: Fig. 4.5 wiring diagram - fixed timers, Fig. 4.7 footvalve assy, Fig. 4.6

4.3

How To Install the Tubing and Fittings

4.3.1

Inlet Tubing - Locate the inlet fitting of the pump head, see fig 4.6. Remove the tube nut. Push the

clear PVC suction tubing onto the compression barb of the fitting. Use the tube nut to secure the tube.

Hand tighten only.

4.3.2

Footvalve/Strainer -Trim the inlet end of the suction tubing so that the strainer will rest vertically

approximately one inch from the bottom of the solution tank. This will prevent sediment from clogging

the strainer. Slip the ceramic weight over the end of the suction tube. Press the footvalve/strainer into

the end of the tube. Secure the ceramic weight to the strainer. Drop the strainer into the solution tank.

Be sure the footvalve does not lay horizontally on the bottom of the solution tank.

4.3.3

Outlet Tubing - Locate the outlet fitting of the pump head, see fig 4.6. Remove the tube nut. Push the

opaque outlet (discharge) tubing onto the compression barb of the fitting. Use the tube nut to secure the

tube. Hand tighten only.

Trim the other end of the outlet tube leaving only enough slack to connect it to the Injection/Check valve

Fitting (see below). Increasing the length of the outlet tube increases the back pressure at the pump head,

particularly when pumping viscous fluids.

Keep the inlet and outlet tubes as short as possible.

C-1700N

C-1700N

Page 6

Page 7

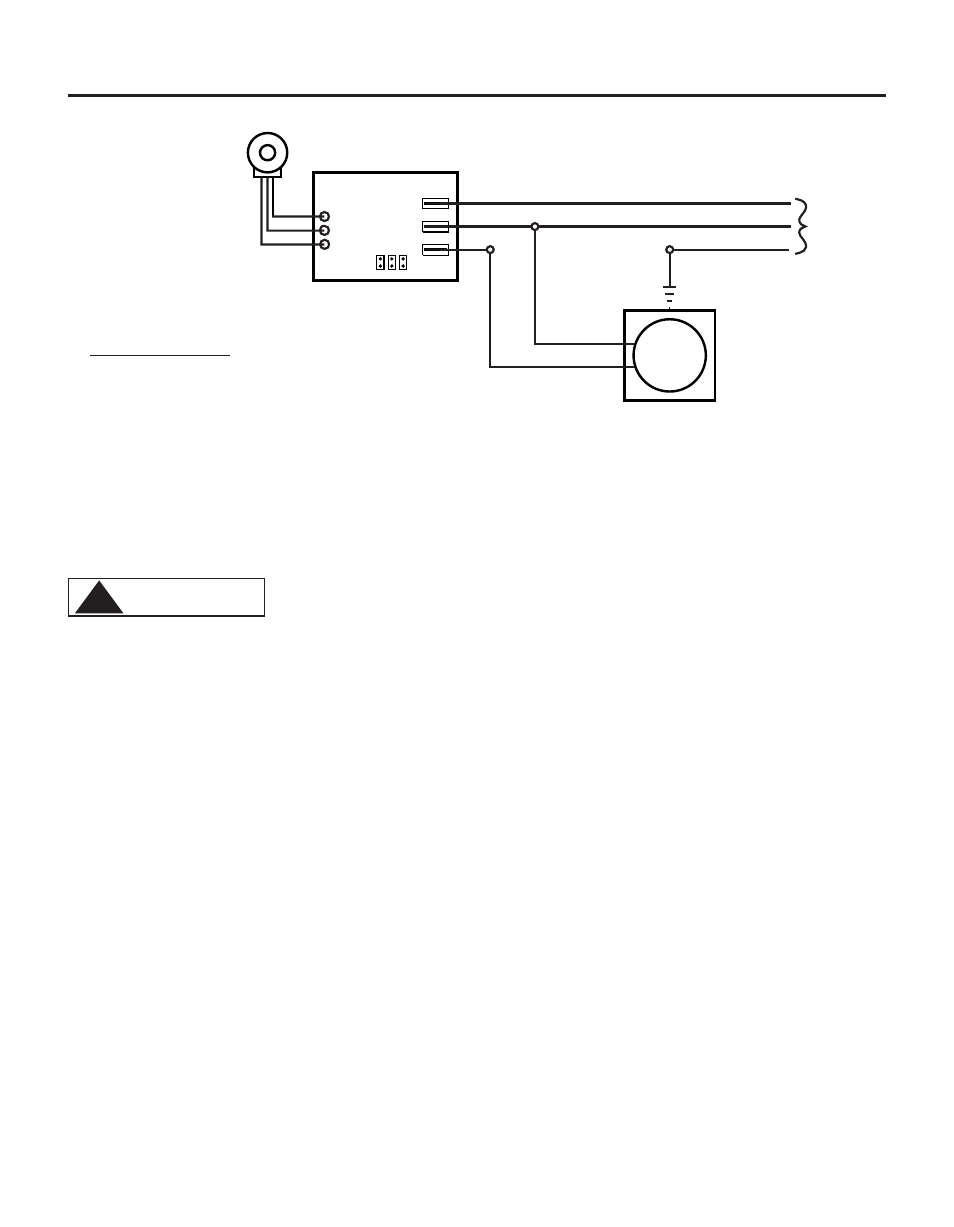

FIG. 4.5 WIRING DIAGRAM - FIXED TIMERS

(factory Setting)

Cycle Adjustment

Potentiometer

T3

T2

T1

AC

Input

Power

Hot

Common

Ground (green)

Timer

Board

Hot

Neutral

AC/LOAD

AC

LOAD

JB2 JB3

JB1

AC

Motor

JB1, JB2, JB3 = Voltage Selector Jumpers

Jumpers Configuration

Install JB2 & JB3, (JB1 left open) = 24 V AC input

Install JB1 & JB3, (JB2 left open) = 115 V AC input

Remove all jumpers (JB1, JB2, & JB3 left open) = 220V, 230 V AC input

FootValve

Sub-Assembly

(in vertical position)

Ceramic

Weight

Suction Tubing

Footvalve Adapter

O-Ring

Ceramic Ball

O-Ring

Footvalve Body

Footvalve Strainer

FIG. 4.7 FOOTVALVE ASSY.

4.3.4

Injection/Check Valve Fitting Installation - The Injection/Check valve fitting is designed to install

directly into either 1/4” or 1/2” female pipe threads.

Install the Injection/Check valve directly into the tee fitting. Do not install the fitting into a pipe stud

and then into the tee. The solution must inject directly into the flow stream.

Use PTFE thread sealing tape on the pipe threads. Push the opaque outlet (discharge) tubing onto the

compression barb of the Injection/Check valve fitting. Use the tube nut to secure the tube. Hand tighten

only.

Injection/Check valve fitting will require periodic cleaning, especially when injecting fluids that calcify

such as sodium hypochlorite. These lime deposits and other build ups can clog the fitting increasing the

back pressure and interfering with the check valve operation. See section 6.0.

FIG. 4.8

INJECTION/CHECK VALVE

TEE INSTALLATION AND EXPLODED VIEW

Discharge Tubes

(Rigid P.E.)

Outlet Adapters

Tube Nuts

Inlet Adapter

(2X)

Tube Nut

(2X)

Suction Tubings

(clear PVC)

FootValves

FIG. 4.6

Pump Head

bracket

Adjustment Knobs

(cam type mechanism)

Proper eye and skin protection must be worn when installing and

servicing the pump.

!

CAUTION