Trouble shooting guide – Amerex 14425 User Manual

Page 7

6

8.

Depress the operating lever and fill extinguisher with the amount of agent specified on the nameplate

USING ONLY CLEAN, UNCONTAMINATED HALOTRON I AGENT. (See detailed instructions on your

recharging system).

CAUTION: AVOID LIQUID HALOTRON I CONTACT WITH EXTINGUISHER CYLINDER. WIPE DRY

IMMEDIATELY WITH A CLEAN CLOTH.

9.

Pressurize to the extinguisher operating pressure with ARGON only. Repeatedly rock the extinguisher

to thoroughly mix the ARGON pressurizing gas until proper pressure is reached. Add additional

ARGON as necessary until the pressure stabilizes.

10.

Check for leaks at the gauge, valve outlet and valve/cylinder connection using a halogen type leak

detector or leak detection fluid. DO NOT USE SOAPY WATER! Thoroughly remove all leak detection

fluid residue from the valve assembly and cylinder. Remove recharge adapter.

CAUTION: IF YOU USE A HALOGEN TYPE LEAK DETECTOR A RESIDUAL AMOUNT OF

HALOTRON I WILL REMAIN IN THE VALVE BODY UNTIL THE LIQUID EVAPORATES. TO

PROPERLY LEAK TEST USING THE HALOGEN LEAK DETECTOR IT IS RECOMMENDED THAT

THE EXTINGUISHER BE SET ASIDE A MINIMUM OF 24 HOURS AFTER RECHARGING, THEN

LEAK TESTING.

11.

Place nozzle or hose and nozzle on scale with extinguisher. Weigh and confirm that the total weight is

within the allowable tolerances indicated in the maintenance section of the extinguisher nameplate.

12.

Install nozzle or hose and nozzle assembly.

13.

Install ring pin with ring facing front of the extinguisher. Install new tamper seal. Record recharge

date and attached new recharge tag.

TROUBLE SHOOTING GUIDE

WARNING: DETERMINE THE SOURCE OF A LEAK BEFORE THE EXTINGUISHER IS

DEPRESSURIZED. THE EXTINGUISHER MUST BE COMPLETELY DEPRESSURIZED BEFORE ANY

ATTEMPT IS MADE TO REMOVE THE VALVE ASSEMBLY AND CORRECT THE LEAKAGE PROBLEM.

SEE INSTRUCTIONS PACKAGE WITH THE AMEREX HALOTRON I RECHARGE KIT P/N 14538 OR

GETZ HALOTRON RECOVERY SYSTEM FOR THE PROPER METHOD OF DEPRESSURIZING THE

EXTINGUISHER TO AVOID UNNECESSARY DISCHARGE AND MINIMUM AGENT LOSS.

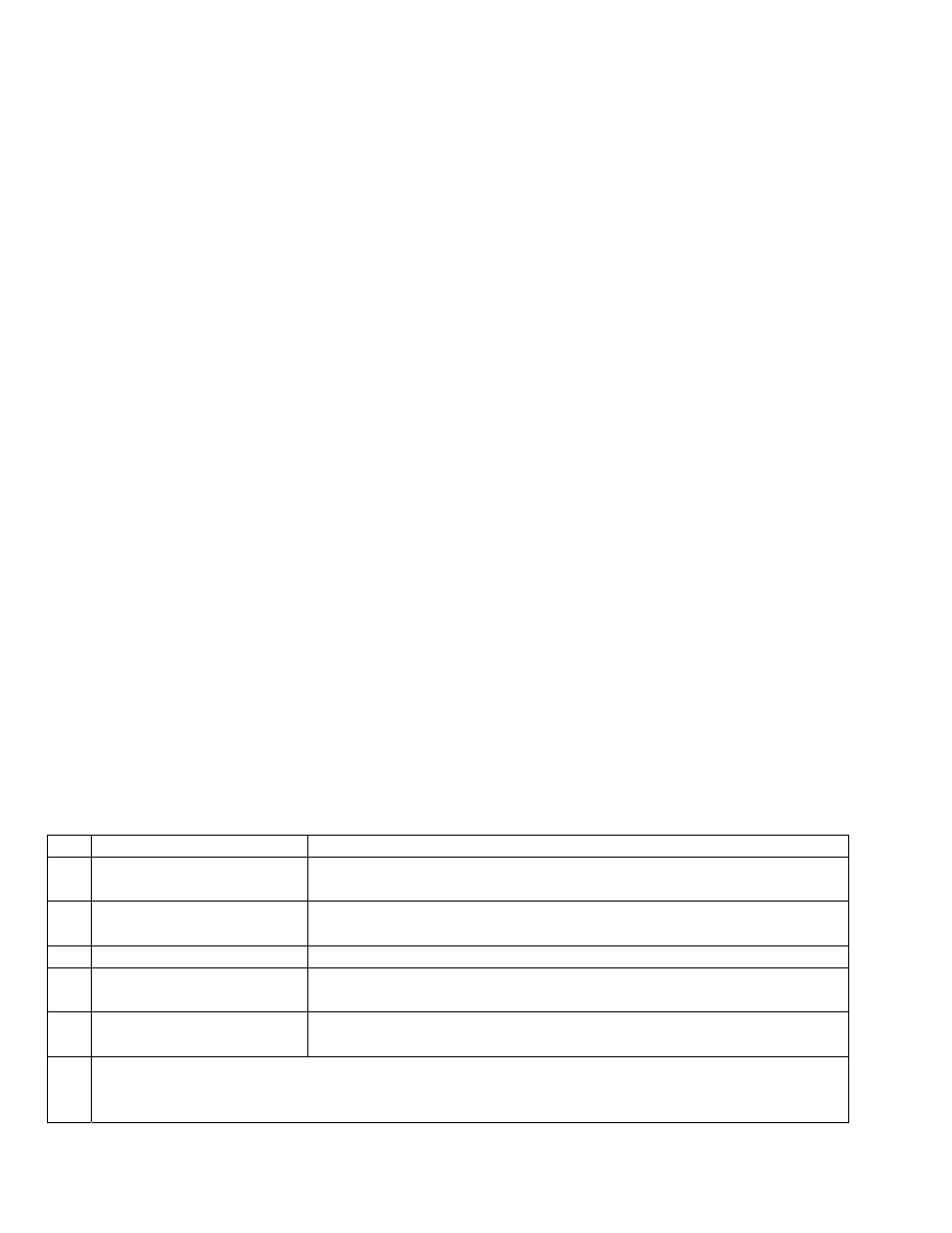

PROBLEM

CORRECTIVE

ACTION

1.

Leak at collar o-ring

Remove valve assembly, clean collar thoroughly and install new ring.

(Optional)

2.

Leak through valve

Install new valve stem assembly. Check valve seat for scratches or

foreign matter

3.

Leak around gauge threads Remove gauge* and reinstall using Teflon tape on the gauge threads

4.

Defective gauge

Remove defective gauge* and install a new gauge using Teflon tape on

the gauge threads.

6.

Leak in cylinder

Contact Amerex if under warranty, otherwise mark “REJECTED” and

return to owner.

*

Pressure gauge threads are coated with a special epoxy at the factory. For easy removal soak the

valve assembly in hot water (180° F/82°C) for two to four minutes. Remove gauge with a 7/16” open

end wrench.