Troubleshooting guide – Amerex 05602 User Manual

Page 7

6

10.

Check extinguisher for leaks by applying detecting fluid or a solution of soapy water to the

nitrogen charging adapter orifice, around the collar o-ring sealing area, cylinder welds and

gauge. Remove the nitrogen charging adapter. Blow air or nitrogen into the interior of the

valve assembly to remove any remaining leak detecting fluid. Wipe exterior of extinguisher

to remove any remaining residue.

11.

Install nozzle or hose and horn assembly.

12.

Install ring pin with ring facing the front of the extinguisher.

13.

Install tamper seal. Record recharge date and attach new recharge tag.

14.

Weigh assembled extinguisher and confirm that the total weight is within the allowable

tolerances indicated in the Maintenance section of the nameplate (label).

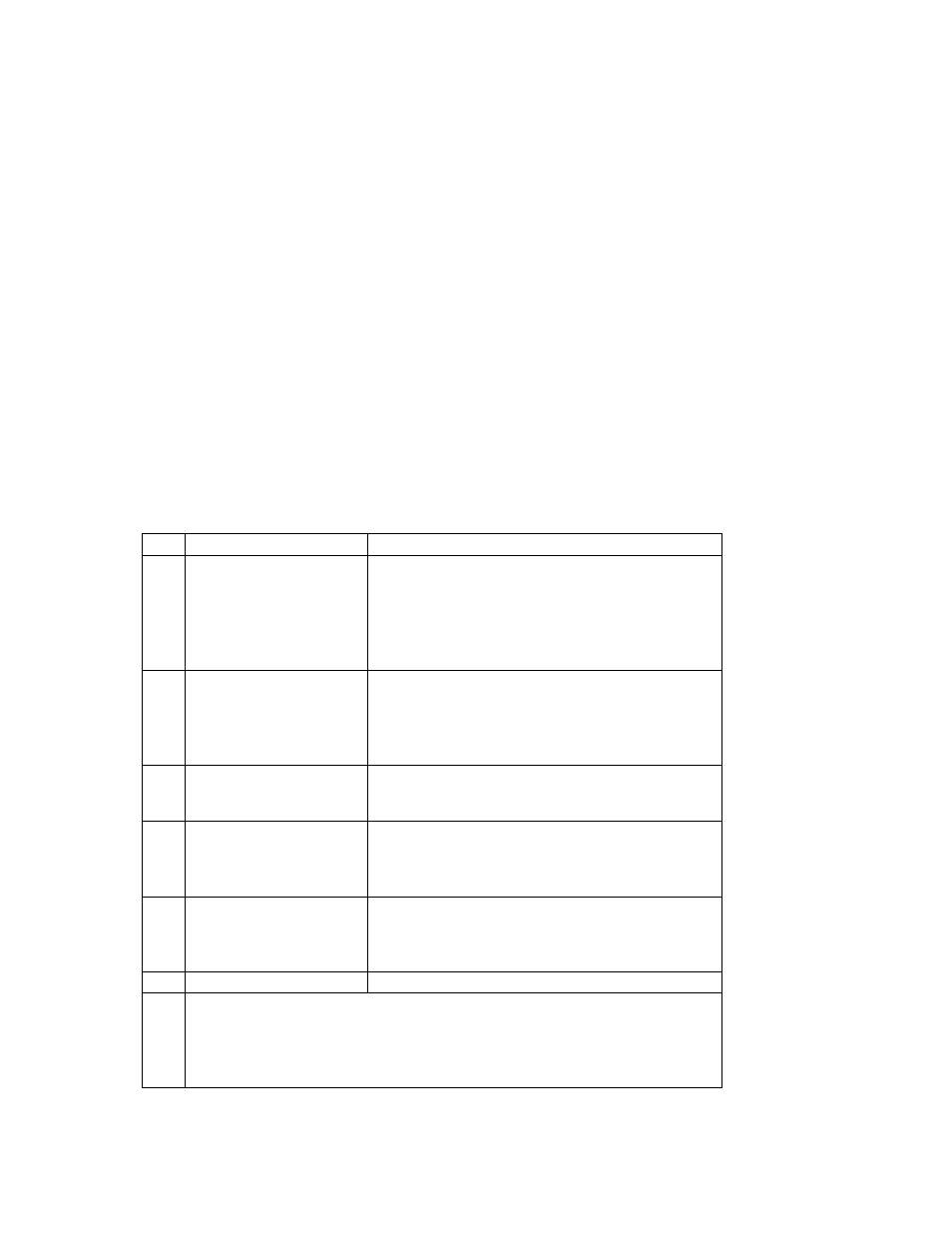

TROUBLESHOOTING GUIDE

WARNING:

Determine the source of a leak before the extinguisher is depressurized. The

extinguisher must be completely depressurized before any attempt is made to devalve it and

correct a leakage problem. To depressurize

– hold the extinguisher in an inverted position and

slowly squeeze the discharge handle. Some chemical remaining in the downtube will be

expelled so care should be taken in the area being used for depressurizing. Thoroughly clean

all valve parts after depressurization and valve removal.

PROBLEM

CORRECTIVE ACTION

1.

Leak at collar o-ring

Remove valve assembly, remove and

discard o-ring, clean collar and lube lightly

with Visilox V-711. Clean o-ring groove on

valve and install new collar o-ring. Lubricate

with Visilox V-711.

2.

Leak through valve

Check valve stem seating area for scratches

or foreign matter. Clean seating area with a

tooth brush and soft cloth. Install new valve

stem assembly.

3.

Leak around gauge

Remove gauge*, clean threads and reinstall

using Teflon tape on the gauge threads.

4.

Defective gauge

Remove defective gauge* an install the

proper Amerex pressure gauge using Teflon

tape on the gauge threads.

5.

Leak in the cylinder

Contact

Amerex

if

under

warranty,

otherwise mark "REJECTED" and remove

from service or return to owner.

* Pressure gauge threads are coated with a special epoxy at the

factory. For easy removal, soak the valve assembly in hot water

(180°F) for two to four minutes. Remove gauge with a thin 7/16"

open end wrench.