Warning – Advanced Protection S50A User Manual

Page 3

Page 3

The voltage rating of the device and system must always be

verified before energizing the SPD. All electrical connections

should be performed by a qualified (licensed) electrician. All

wiring must comply with the National Electrical Code (NEC)

and applicable local codes.

• Maintenance of this Surge Protective Device should

be performed by qualified electrical personnel only.

• During normal operation, hazardous voltages are

present inside the unit.

• When servicing this unit, be sure to follow all electrical

safety precautions.

• All power sources to this unit should be locked off

before servicing. This will prevent the risk of receiving

an electrical shock.

WARNING

VERIFY ALL POWER CIRCUITS ARE DE-ENERGIZED

BEFORE MAKING CONNECTIONS

!

S50A is a Type 1 SPD. S50A is suitable for use almost

anywhere (not as a plug-in SPD). Type 1 SPDs are

evaluated more rigorously by UL 1449 for 2008 NEC®

Article 285 compliance. Type 1 SPDs and their connecting

leads have been evaluated for line side applications

without need for supplemental overcurrent protection.

Type 1 SPDs include internal overcurrent protection. As a

generalization, there are practical maintenance reasons for

installing on the load side of the main overcurrent device

(i.e. Type 2 installation). When connected on load side of

main disconnect, we recommend connecting via a 30A

circuit breaker due to 10 AWG conductors. The circuit

breaker serves as a disconnect switch and provides NEC®

imposed short circuit protection to the conductors in Type

2 or 4 applications. (cUL units are Type 2 due to different

cUL criteria.)

Installation

Pre-Plan your installation. You need to accomplish the

following:

• Meet all National and Local codes (NEC

®

Article

285 and UL 1449 address SPDs)

• Confirm System voltage to SPD voltage (120V

SPD will fail instantly on 240V, 277V, etc.)

• Mount SPD as close to panel or equipment as

possible to keep leads short (long leads hurt

performance substantially)

• Ensure leads are as short and straight as

possible, including neutral. If using a breaker,

use a breaker position that is close to the SPD

and the panel’s neutral

• If using a breaker, recommended breaker size is

30A due to 10 AWG conductor

• Make sure system is grounded per NEC

®

and

clear of faults before energizing SPD (inadvertent

system problem may fail SPD).

• Never Hi-Pot test Any SPD (will prematurely fail

SPD)

1. Use voltmeter to check voltages and ensure correct

SPD. See Data Sheet for specs & wire-outs

2. Determine Mounting method (See Figure 2) –

weather resistant equipment may be required

3. Remove power from panel/source. Confirm panel/

source is deenergized.

4. Identify breaker location and SPD location. Position

SPD such that LED is best visible.

5. Mount SPD – weather resistant applications require

additional sealing, o-rings, etc. (not included)

- Remove an appropriately sized knockout from

panel.

- Connect conductors as appropriate – short and

straight as possible

6. Label or mark conductors as appropriate (neutral:

white, energized: black)

7. Make sure system is bonded per NEC

®

and is clear

of hazards or faults before energizing (N-G bonding

not per NEC

®

will fail SPDs: #1 cause of SPD

failures)

8. Energize and confirm proper operation of green LED

indicator and/or options.

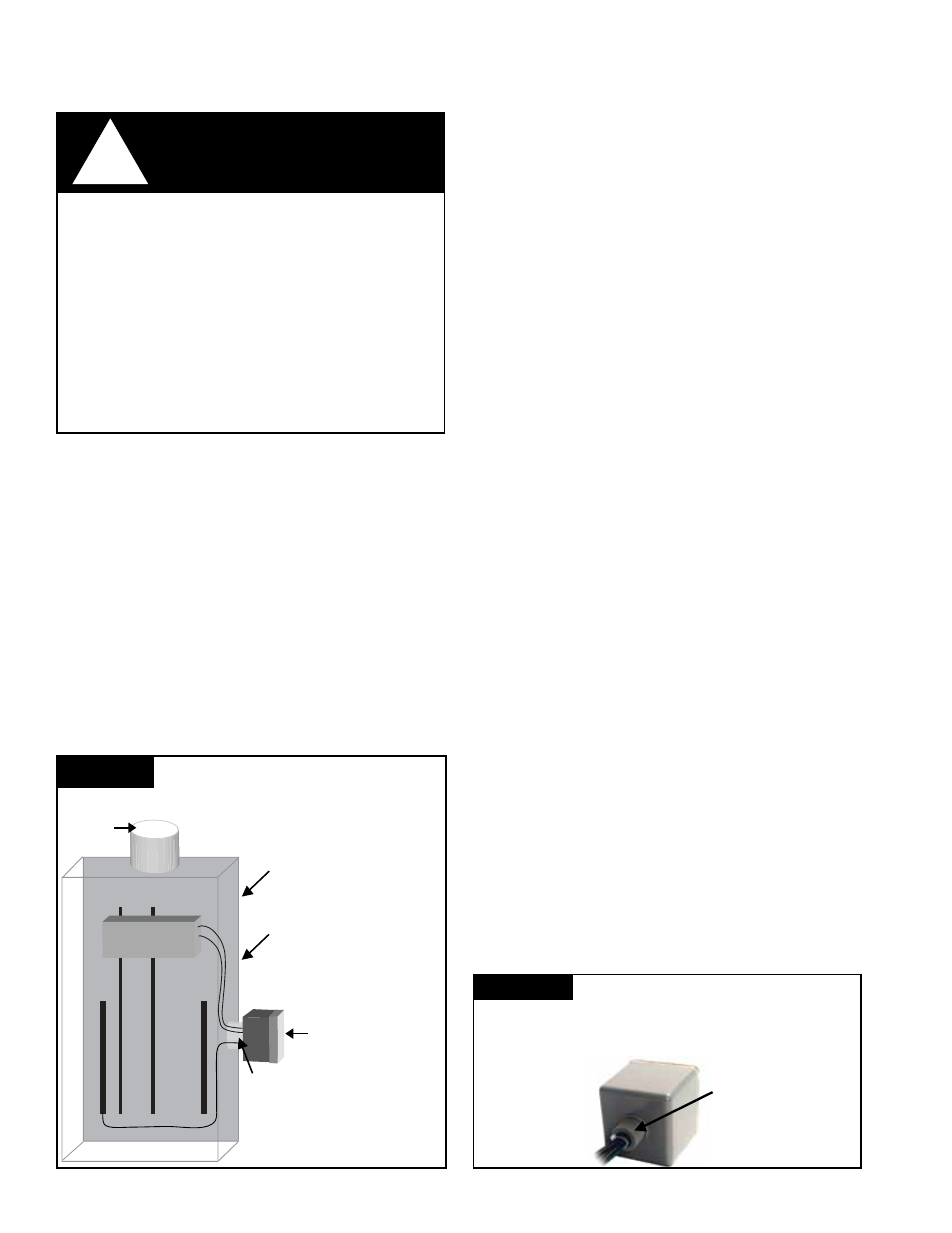

A

B

G

N

BREAKER

Typical Panel Installation

(Type 1 or individual equipment installations may vary)

• Use closest breaker to

SPD

• Locate SPD close to

intended breaker

• Keep Leads Short as

Possible

• Avoid Sharp Bends

• Outdoor installation requires

appropriate weather sealing

at nipple (gasket, sealing

conduit, etc.)

To Protected

Loads

Figure 1

• Rotate S50A such

that LED indicator is

most visible

Sealing gasket: two choices

1.) At 3/4" nom. thread: ID is 1.05"

2.) At 0.14" high 'base step': ID is 1.25"

Figure 2