Functions menu, Specification, Second setpoint (sp2) – West Control Solutions 3300 User Manual

Page 2: Error messages, Function list (levels 1 to 4)

SECOND SETPOINT (SP2)

SECOND SETPOINT (SP2) Alarm Output

Configure SP2 output to operate as an alarm from SP2.A in Level 2 and set the temperature alarm setting in SEt.2 Level 1. The

alarm will be triggered when the process temperature changes according to the options listed below.

dV.hi

Rises above the main setpoint by the value inserted at SEt.2.

dV.Lo

Falls below the main setpoint by the value inserted at SEt.2.

Band

Rises above or falls below the main setpoint by the value inserted at SEt.2.

FS.hi

Rises above the main setpoint by a SEt.2 value that is greater than the setpoint.

FS.Lo

Falls below the main setpoint by a SEt.2 value that is smaller than the setpoint.

SUBSIDIARY SP2 MODE

The following additional alarm functions can be added to the above alarm configurations using the features found in SP2.b in Level 2

LtCh

Once activated, the alarms will latch and can be manually reset when the alarm condition has been removed.

Hold

This prevents any alarm operation on power-up and is automatically disabled once the process reaches setpoint in

order to allow normal alarm operation.

Lt.ho

Combines the effects of both LtCh & Hold and can be applied

SECOND SETPOINT (SP2) Proportional control output

Configure in Level 1 using CyC.2 to select proportional cycle time and bnd.2 to adjust proportioning band.

- For Heat/Cool operation see full operating manual.

- In on/off mode, bnd.2 adjusts SP2 hysterisis.

SP2 OUTPUT AND LED INDICATION STATES - IN ALARM CONDITION

SP2 ALARM ANNUNCIATOR

When an SP2 alarm mode is selected in SP2.A the alarm annunciator -AL- is displayed, alternating with the process temperature,

during alarm condition.

Notes: The alarm will be automatically reset when the temperature returns within the bnd.2 setting in Level 1.

The annunciator may be disabled by selecting function no.AL : on in level 4.

SP2 in cool strategy

See full operating manual (ADVANCED SETTINGS)

ERROR MESSAGES

Display Flashes

Fault Type

Action

inPt: FAiL

SENSOR FAULT

Thermocouple burnout RTD/Pt100 open or short circuit

or negative over-range.

Check sensor/wiring

dAtA : FAiL

NON-VOLATILE MEMORY ERROR

De-power briefly.

Replace unit if problem persists

hAnd : FAiL

MANUAL POWER ERROR

SP1 set to ON/OFF in CYC.t

Select proportional mode

tunE : FAiL

IMMEDIATE FAIL ON AUTOTUNE START

Note: To reset and clear error press

▲

▼

together briefly to cancel message.

1. If display setpoint=0 then enter setpoint

2. If SP1 set to ON/OFF in CyC.t then

select proportional mode

FAIL LATER DURING AUTOTUNE CYCLE

The thermal characteristics of the load exceed the

autotune algorithm limits. The failure point is indicated by

any display 0.0 in tech e.g. Ctb = 0.0

1. Change conditions. eg. raise setpoint

2. Try tunE : At.SP

3. If the error message persists, call local

CAL representative for advice.

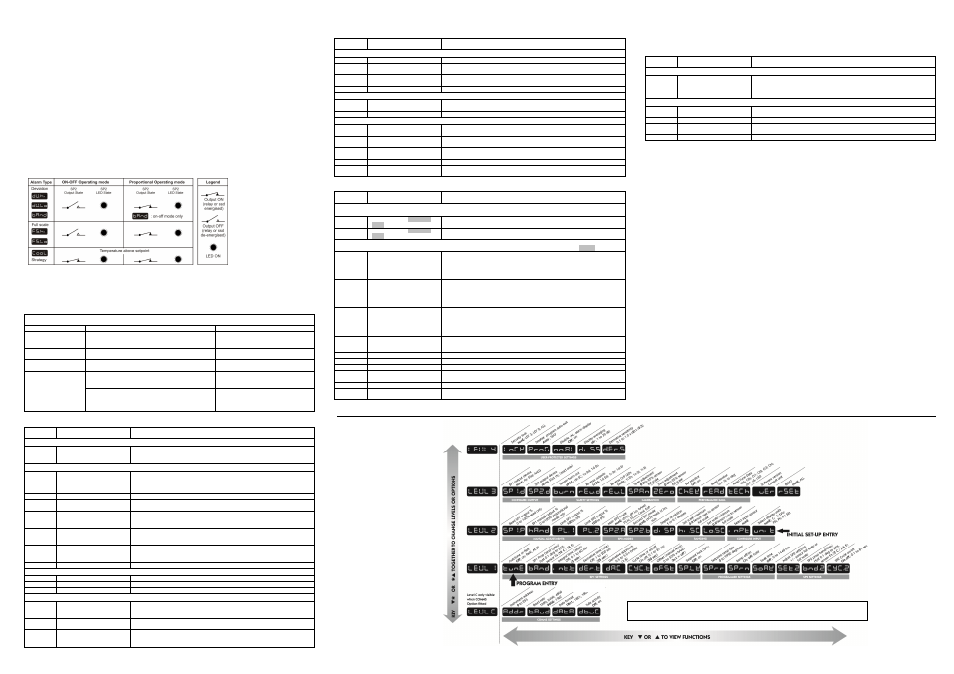

FUNCTION LIST (LEVELS 1 TO 4) -

LEVEL 1

Function

Options [Factory settings]

shown in brackets

Description

Select Autotune

tunE

[oFF], on, ParK, At.Sp

Used to switch the Autotune feature on and off, to select ParK or tune at setpoint.

ParK temporarily turns the output(s) off. To use select ParK and exit program

mode. To disable re-enter program at tunE and select oFF.

SP1 Operating Parameters

bAnD

0.1 to * C/°F [10ºC/18ºF]

SP1 proportional band/Gain or Hysteresis

* 25% sensor maximum Proportional control eliminates the cycling of on-off

control. Heater power is reduced, by time proportioning action, across the

proportional band.

int.t

oFF, 0.1 to 60 minutes [5.0]

SP1 integral time/reset Auto-corrects proportional control offset error

dEr.t

oFF 1 - 200 seconds [25]

SP1 derivate time/rate Suppresses overshoot and speeds response to

disturbances

dAC

0.5 - 5.0 x bAnd [1.5]

SP1 derivative approach control dAC Tunes warm-up characteristics,

independent of normal operating conditions, by controlling when derivative action

starts during warm-up (smaller dAC value = nearer setpoint).

CyC.t

A – –, on.oF, 0.1 - 81 sec [20]

SP1 proportional cycle-time (see section above)

Determines the cycle rate of the output device for proportional control. Select

on.oF for ON/OFF mode.

oFSt

[0] to * °C/°F

SP1 offset/manual reset

* ±50% bAnd. Applicable in proportional and ON/OFF mode with integral disable:

Int.t : oFF.

SP.LK

[oFF] on

Lock main setpoint Locks the setpoint preventing unauthorised adjustment.

Programmer Settings

SPrr

[0] to 9995 deg/hour

Sets the ramp rate

SPrn

on [oFF] hold

Switches the ramp on or off, or hold at last ramp value

SoAK – –

[oFF] 0 to 1440 min

Sets the soak time

SP2 Operating Parameters

SEt.2

0 to * °C/°F [0]

Adjust SP2 setpoint

* Deviation Alarms DV.hi, DV.Lo, bAnd 25% sensor maximum.

* Full scale alarms FS.hi, FS.Lo sensor range f/s

bnd.2

0.1 - * °C/°F [2.0 °C/3.6°F]

Adjust SP2 hysteresis or proportional band/gain (see CyC.2 setting)

* 25% of sensor full scale

CyC.2

[on.oFF] 0.1–81 seconds

Select SP2 ON/OFF or proportional cycle-time

Select on.oFF for ON/OFF mode, or the cycle rate of SP2 output device for

proportional mode.

LEVEL 2

Function

Options [Factory settings]

shown in brackets

Description

Manual Control Modes

SPI.P

0 to 100 % ‘read only’

Read SP1 output percentage power

hAnd

[oFF] 1 to 100 % (not in

ON/OFF)

SP1 manual percentage power control For manual control should a sensor fail.

Record typical SP1.P values beforehand.

PL.1

100 to 0 % duty cycle [100]

Set SP1 power limit percentage Limits maximum SP1 heating power during

warm-up and in proportional band.

PL.2

100 to 0 % duty cycle [100]

Set SP2 percentage power limit (cooling)

SP2 Operating Modes

SP2.A

[none] dV.hi dV.Lo bAnd

FS.hi FS.Lo Cool

Main SP2 operating mode

SP2.b

[none] LtCh hoLd nLin

Subsidiary SP2 mode: latch/sequence ,Non-linear cool proportional band

Input Selection and Ranging

dI.SP

[1] 0.1

Select display resolution: for display of process temperature, setpoint, OFSt,

Set.2, hi.SC, LoSC

hi.SC

sensor minimum [sensor

maximum] °C/°F

Set full scale

Lo.SC

[sensor minimum] sensor

maximum °C/ºF

Set scale minimum (default 0°C or 32°F)

inPt

[nonE]

Select input sensor (See SENSOR SELECTION table)

Unit

[nonE] °C °F bAr Psi Ph rh

SEt

Select °C/°F or process units

LEVEL 3

Function

Options [Factory settings]

shown in brackets

Description

Output Configuration

Note: ‘Read only’ after initial configuration. rSET ALL full reset to factory settings required to change SP1.d subsequently.

SP1.d

[nonE] rLY SSd rLY1 rLY2

SSd1

Select SP1 output device

Dual Relay and Dual SSd output options are factory set.

SP2.d

[nonE] SSd rLY rLY2 rLY1

SSd2

Read SP2 output device(read only)

Dual Relay and Dual SSd output options are factory set.

For SP1.d & SP2.d

Note: (when in initial configuration only) Hold

and

▲

or

▼

for 10 seconds to move to or from output options shaded.

burn

SP1 / SP2

[uP.SC] Upscale/Upscale

dn.SC Downscale/Downscale

1u.2d Upscale/Downscale

1d.2u Downscale/Upscale

Sensor burn-out/break protection

Caution: Settings affect fail safe state.

rEu.d

SP1 / SP2

[1r.2d] Reverse Direct

1d.2d Direct Direct

1r.2r Reverse Reverse

1d.2r Direct Reverse

Select output modes: Direct/Reverse

Select Reverse on SP1 for heating and Direct for cooling applications.

Caution: Settings affect fail safe state.

rEu.L

SP1 / SP2

[1n.2n] Normal Normal

1i.2n Invert Normal

1n.2i Normal Invert

1i.2i Invert Invert

Select SP1/2 LED indicator modes

SPAn

[0.0] to ±25% sensor

maximum

Sensor span adjust

For recalibrating to align readings with another instrument e.g. External Meter,

data logger. See Full Operating Manual (ADVANCED SETTINGS).

ZEro

[0.0] to ±25% sensor f/s

Zero sensor error (see Sensor span adjust above).

ChEK

[oFF] on

Select control accuracy monitor

rEAD

[Var] hi Lo

Read control accuracy monitor

tECh

[Ct A] CT b Ct 1 Ct 2 Ct 3 Ct

4 oS 1 uS oS 2

Read Autotune tuning cycle data (see Operating Manual)

UEr

Software version number

rSET

[nonE] ALL

Resets all functions to factory settings

Caution: This selection will lose all of the current settings.

FUNCTIONS MENU

LEVEL 4

Access to level 4 is gained through UEr in level 3. Press and hold

▲

or

▼

for 10 seconds.

Enter level 4 at Lock, release

▲

or

▼

together. Display reads LoCK nonE

Function

Options [Factory settings]

shown in brackets

Description

Security

LoCK

[none] LEV.3 LEV.2 ALL

Program security using Lock

LEV.3 locks level 3 and 4 only- Technical Functions.

LEV.2 locks levels 2, 3 and 4 only - Configuration and technical Functions.

ALL locks all functions LoCK ALL

Function Options

ProG

[Auto] StAY

Program mode auto-exit switch. Auto-exit returns display to normal if 60

seconds of key inactivity, select StAY to disable

no.AL

[oFF] on

Disable SP2 alarm annunciator–AL Select on to disable -AL

di.SS

Dir, 1 to 32 [6]

Display sensitivity

dir = direct display of input 1 = maximum, 32 = minimum sensitivity

dEr.S

0.1 to 1.0 [0.5]

Derivative sensitivity

SPECIFICATION

Thermocouple

9 types

Standards:

IPTS/68/DIN 43710

CJC rejection:

20:1 (0.05°/°C) typical

External resistance:

100Ω maximum

Resistance thermometer RTD-2/Pt100 2 wire

Standards:

DIN 43760 (100Ω 0°C/138.5Ω 100°C Pt)

Bulb current:

0.2mA maximum

Linear process inputs

mV range:

0 to 50mV

Applicable to all inputs SM = sensor maximum

Calibration accuracy:

±0.25%SM ±1°C

Sampling frequency:

input 10Hz, CJC 2 sec.

Common mode rejection: Negligible effect up to 140dB, 240V, 50-60Hz

Series mode rejection:

60dB, 50-60Hz

Temperature coefficient: 150ppm/°C SM

Reference conditions:

22°C ±2°C, rated voltage after 15 minutes settling time.

Output devices

SSd/SSd1/SSd2:

solid state relay driver: To switch a remote SSR 5Vdc +0/-15% 15mA non-isolated

Miniature power relay:

form A/SPST contacts (AgCdO) rLY and rLY1: 2A/250ac resistive load rLY2: 1A/250ac resistive load

General

Displays:

Upper, 4 Digits, high brightness green LED. 10mm (0.4”) high.

Lower,

4 Digits, Orange LED. 9mm (0.35”) high (dual display version only)

Digital range -

-199 to 9999

Hi-res mode -

-199.9 to 999.9

LED output indicators -

flashing, SP1 square, green; SP2 round, red

Keypad:

3 elastomeric buttons

Environmental

Humidity:

Max 80%

Altitude:

up to 2000M

Installation:

Categories ll and lll

Pollution:

Degree ll

Protection:

NEMA 4X, lP66

EMC emission:

EN50081-1 FCC Rules 15 subpart J Class A

EMC immunity:

EN50082-2

Ambient:

0-50ºC (32-130°F)

Mouldings:

flame retardant polycarbonate

Weight:

1/32 DIN - 110g (3.9oz), 1/16 DIN single display - 120g (4.2oz), 1/16 DIN dual display - 130g (4.6oz).

Approvals

CE, UL (file number E81867), cUL, FM (3545)

Note: Applications where controller may be subjected to 110MHz –130MHz radiated RF (common in aeronautical environments)

If using the 12-24V variant fitted with RS232/485 comms option, individual Ferrites (Wuerth Elektronik, Part 742 711 31, or similar)

must be fitted to all incoming and outgoing cables, at the point of entry / exit to the controller.

Range of Adjustment shown under description. If applicable, factory settings shown in bold.

Note: The letter K appears in the instrument display as the character K