Thermo Fisher Scientific ECDOTPII-S Submersible Galvanic Dissolved Oxygen Sensor User Manual

Page 3

www.thermofisher.com

MEMBRANE TYPE

Two types of membrane materials are offered for DO sensors, either PTFE or HDPE. Teflon offers excellent

durability and moderate speed of response. HDPE offers fast response but less mechanical strength. The

PTFE membrane also has less membrane permeability error with temperature as compared to HDPE.

Spare membranes are available is 5 or 25 counts, or in maintenance kits.

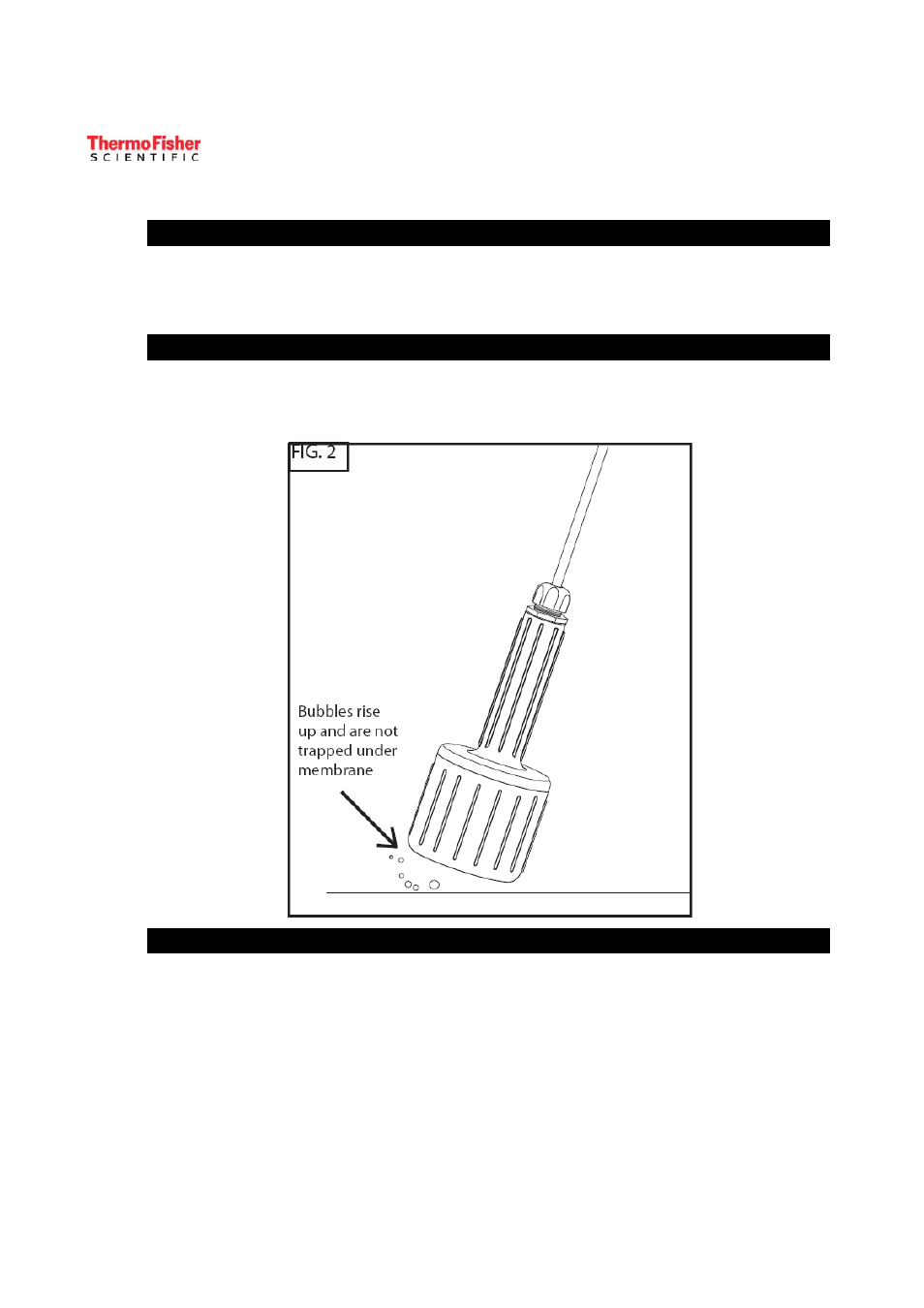

MOUNTING YOUR DO SENSOR

Submersion mounting of the sensor is recommended. To prevent air bubbles from becoming trapped on

the membrane and producing falsely high DO readings, it is recommended that the sensor be mounted

with the membrane pointing slightly upward (not horizontal) as shown in FIG. 2.

SENSOR RE-CONDITIONING

1. Unscrew the lower body from the upper body(FIG. 3)

2. Safely dispose of the electrolyte that is a special molarity, reagent grade Sodium Chloride

solution (salt water) as shown in FIG. 4

3. Using the Membrane Tool, unscrew the Membrane Lock in the lower body as shown in FIG. 5

4. Remove and dispose of the membrane and its O-Ring as show in FIG 6

5. Using a toothbrush, dishwashing powder and clean water, clean the cathode, anode, and plastic

between them. Rinse all components thoroughly. Household Ammonia may be used to clean

the silver anode overnight If Ammonium Hydroxide is used, expose it for no more than 3

minutes (it is very strong). See FIG. 7.

6. Install a new O-Ring into the lower body membrane cavity then a new membrane into the lower

body. Using the Membrane Tool, screw the Membrane Lock on top of the membrane as shown

in FIG. 8.

7. Inspect the membrane for wrinkles--replace if it is wrinkled.

8.

Pour some water into the lower body and look for leakage around the membrane--replace it if

there is leakage. If no leakage, dispose of the water.