Techne Liquid Calibration Bath User Manual

Techne Equipment

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

7

You will need to remove the cooling coil when you are using

the thermoregulator on one of the Techne Calibration Baths.

Remove the screw which is used to fit the cooling coil to the

base of the unit. Keep the cooling coil in a safe place in case

you need to replace it.

A cooling coil is fitted to the bath. Connect a hose from a tap

to one end of the coil and from the other end of the coil to

drain. Adjust the water flow to give the required cooling.

8

For lower temperatures a Flow Cooler, such as the Techne

FC-200 or FC-500 is required.

See the instruction Manuals for these units for

connections and setup.

9

Fill the bath to between the minimum and maximum levels

stated in the specification.

If you are using oil at the highest temperatures, remember that

they will expand as the temperature rises. Even if you fill

the bath with oil to the minimum level, it may well

reach the maximum level before the top temperature

is reached. Take all precautions and monitor the level

through the full range.

If water is used, demineralised water is preferred to reduce

the formation of scale. If scale should form, use only mild de-

scaling agents to remove it. DO NOT attempt to hammer, chip

or scrape the deposits from the surface of the bath

10 Recommended liquids:

Temperature Liquid

-40

o

C to 0

o

C 40% water 40% ethylene glycol 20% alcohol

-20

o

C to 30

o

C 50% water 50% ethylene glycol

5

o

C to 95

o

C water, preferably de-ionised with neutral pH

10

o

C to 150

o

C Dow Corning Silicone Oil 200 series *

10°C to 250°C Dow Corning Silicone Oil 210H/100cs series *

* Warning: check gel life at top end of range.

Extraction may be necessary at high temperatures; always

check the manufacturer's data and safety sheets before

using any of the liquids.

In all cases the OVERTEMPERATURE CUT-OUT must be set

correctly for the liquid being used and the temperature at

which it is to operate

11 If you are using a low viscosity oil with a TU-20C controller,

the pump on the controller may be too powerful and cause

the oil to splash from the bath. There is a flow restrictor

supplied with the Calibration Bath. Push the "top hat"

restrictor into the outlet of the pump and fit the retaining plate

over it. Remove the appropriate screw from the pump and fix

the retaining plate with the same screw.

12 A bath that is fitted with a lid or insulating ball blanket gives

the best operating conditions. A lid or ball blanket will

prevent vapour loss, heat loss and give better temperature

control. If an open bath is used above 80

o

C (ie where steam

or other readily condensing vapours are present) the

operation of the unit, particularly the digital display, may be

affected.

Below about 80

o

C a cover becomes less important but will still

give better temperature control.

The Calibration Bath

Make sure you have read this manual carefully before you use

the thermoregulator.

Techne supply a range of liquid calibration baths from 5 to 12

litres on which you can fit one of the thermoregulator range of

units. The bath inner containers are manufactured from

stainless steel, for maximum corrosion resistance. The 5 and 7

litre baths are deep drawn with large easy clean corner radii.

The 12 litre bath is of welded construction.

The thermoregulator is designed to fit all standard laboratory

baths, especially Techne baths. It will heat, circulate and

safely control the temperature of the liquid in the bath within

precise limits.

See the Operator's manual for full operating details for

the thermoregulator.

Set Up

1

There are two modes of operation for the pump; circulation

internal to the bath; circulation external to the bath.

For internal circulation the blanking caps on the top of the

outlet and return pipes should be securely in place. They

screw on and, for safety, they may be tight.

For external circulation the blanking caps need to be

removed. With the blanking cap removed, and an external

circuit set up, the liquid will be split between internal flow

and external flow.

2

CAUTION: DO NOT SWITCH THE THERMOREGULATOR

ON UNLESS EITHER THE BLANKING PLUGS ARE FITTED

TO THE TOP OF THE PIPES or AN EXTERNAL CIRCUIT IS

FULLY CONNECTED.

IF YOU ARE PUMPING TO AND FROM A SECOND OPEN

BATH A RESTRICTION MUST BE PUT ON THE PRESSURE

SIDE OF THE PIPES. THE PRESSURE VOLUME IS GREATER

THAN THE SUCTION VOLUME AND YOU COULD OVER-FILL

THE SECOND BATH

3

Ensure that the bath is set up on a flat level surface.

4

Fit the unit securely to the bath. THE UNIT MUST ALWAYS

BE MOUNTED WITH THE BACK AND THE SWITCH END

OUTSIDE THE AREA OF THE BATH. This will reduce the

infiltration of hot vapours into the cooling system of the

thermoregulator. Ensure that at all times the air inlet and

outlet remain clear of obstructions. Free circulation of air

inside the unit is essential for proper cooling of the

electronics and pump motor.

5

The Thumb Screw secures the unit to the bath at the mains

Switch end.

6

If the pump has been set correctly for external circulation,

suitable hoses should be fitted to the outlet and return pipes.

A suitable hose must be capable of withstanding both the

temperature of operation and the liquid being used. Always

securely clip the hoses in place.

Material Allowable Temperature Range Comments

PVC

10°C to 60°C (50°F to 140°F) For water only

Silicone -40°C to 200°C (-40°F to 362°F)NOT for silicone oil

Viton

-20°C to 250°C (-4°F to 482°F)

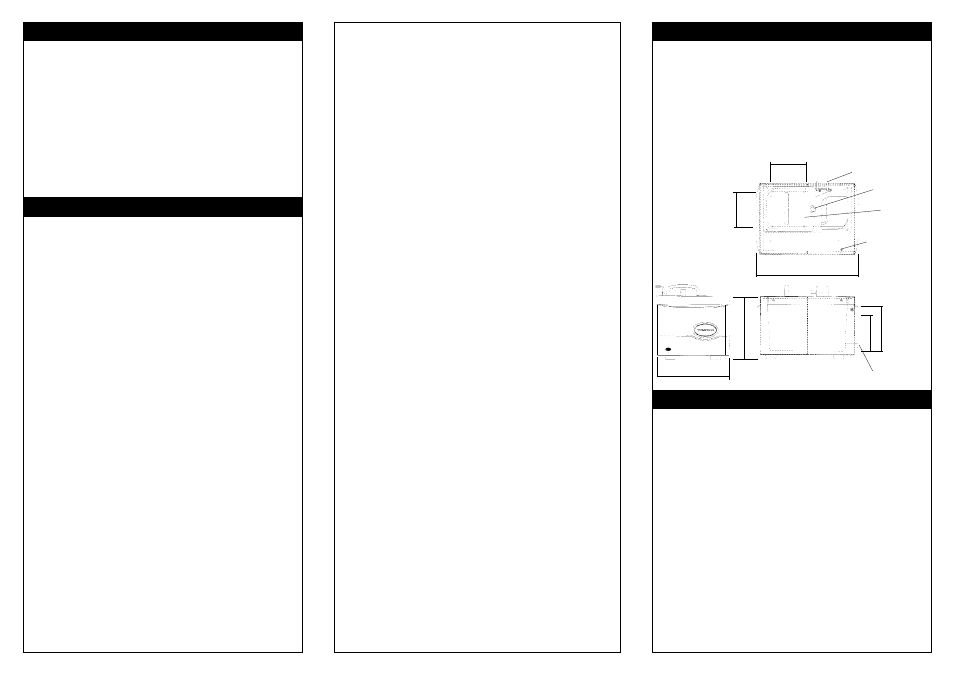

Bath Sizes

Bath

LCB-5

LCB-7

LCB-12

Overall Length

A

351 mm

351 mm

351 mm

Overall Width

B

260 mm

260 mm

260 mm

Overall Height

C

183 mm

233 mm

358 mm

Opening Length

D

140 mm

140 mm

140 mm

Opening Width

E

140 mm

180 mm

140 mm

Max. Working Depth F

130 mm

140 mm

305 mm

Min. Working Depth

G

90 mm

90 mm

265 mm

Maximum Capacity

5.0 l

6.5 l

12.0 l

Minimum Capacity

4.0 l

5.5 l

11.0 l

D

Cooling Coil

Standard Probe

Entry

E

Lid

Thermoregulator

Fixing Point

A

C G F

B

Drain Point

Working Environment

The units are designed to work safely under the following

conditions:

Ambient temp. range 5°C to 40°C

Humidity

Up to 95% relative humidity, non-condensing

Note: The control specifications quoted are for an ambient

temperature range of 10°C to 30°C. The specification

may deteriorate outside this range but the unit will still

work safely.

Radio frequency interference tested and passed to

EN50081-1.

Immunity Tested and passed to

EN50082-1