Ar ch ive d – Seametrics AG2000 v.1 User Manual

Page 2

Page 2

INSTALLATION

Tamper-Evident Seal. The battery-powered AG2000 has

a seal wire to protect against unauthorized access. The

seal can be broken to change units of measure, replace

the battery pack, or to field-install a power/output cable. If

water usage regulation is in effect, only a person authorized

by your regulatory agency should break the seal wire, and

replace it when finished.

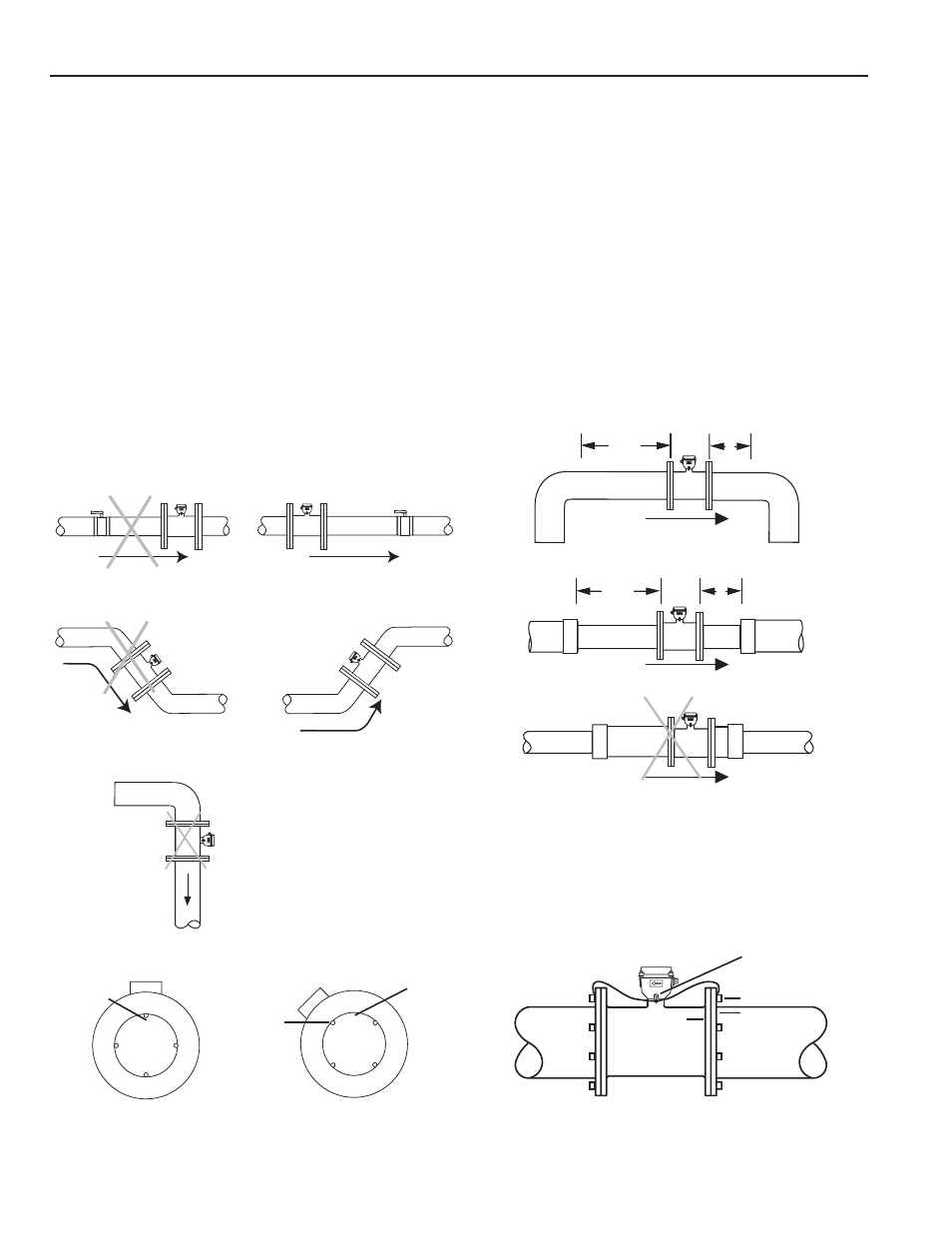

Positioning the Meter. These meters can be installed

horizontally, vertically, and in any radial position. If sludge

accumulation is a potential problem, vertical or horizontal

placement with the register angled may be preferred.

Full Pipe Recommendations. All magmeters require a

method for determining that the pipe is empty, to prevent

false reading. This meter is designed to go to zero reading

if one or more electrodes is exposed. For highest accuracy,

install the meter so that the pipe will be full when there is

flow. If air bubbles may be present in the pipe, rotate the

meter by one flange hole to position the control housing at

a 45˚ angle. See Full Pipe diagrams below.

Possible Problem: Air pockets,

accuracy loss, empty pipe reading

Better Installation: Keeps pipe full

at sensor for accuracy

Possible Problem: Air can be

trapped, loss of accuracy

Better Installation: Allows air

to bleed off, higher accuracy

Fittings. The AG2000 flanges have standard ANSI 150 lb

drilling, and should match up with any other ANSI 150 lb

flange.

Temperature. These flow sensors are not recommended

for installation where temperature exceeds 130˚ F.

Calibration. The AG2000 is factory calibrated and should

not require any form of field calibration.

Protecting the Meter. To protect the AG2000 against

environmental assaults, you may wish to install a weather

guard (part #31388).

Straight Pipe Recommendations. See the diagrams below

for the type of installation that best matches yours.

2X

1X

2X

1X

pipe size

pipe size

pipe size

pipe size

Elbows

Reduced Pipe

(not recommended)

Expanded Pipe

Possible Problem: If air bubbles are

present, they can pass over top measure-

ment electrode; meter reads “empty pipe”

Better Installation: If air bubbles

are present they will pass between

electrodes; meter reads “full pipe”

Electrode

moved from

top by rotating

meter

Intermittent air

bubbles

miss electrode

Not Recommended:

Vertical downflow,

open discharge

Grounding Diagram

Grounding Lug

Meter Flange

Pipe Flange

Bolt

Run grounding wire from grounding lug to

both pipe flanges; secure under bolt head.

Intermittent air

bubbles

pass over

electrode

Grounding. It is important to ground your meter. To do

this, run grounding wire from the grounding lug to both pipe

flanges, securing the wire to the flanges at one of the bolt

holes. See diagram below.

AR

CH

IVE

D

(Includes Dates 7/19/06 to 1

1/06)