Seametrics TX100-200-SERIES User Manual

Page 8

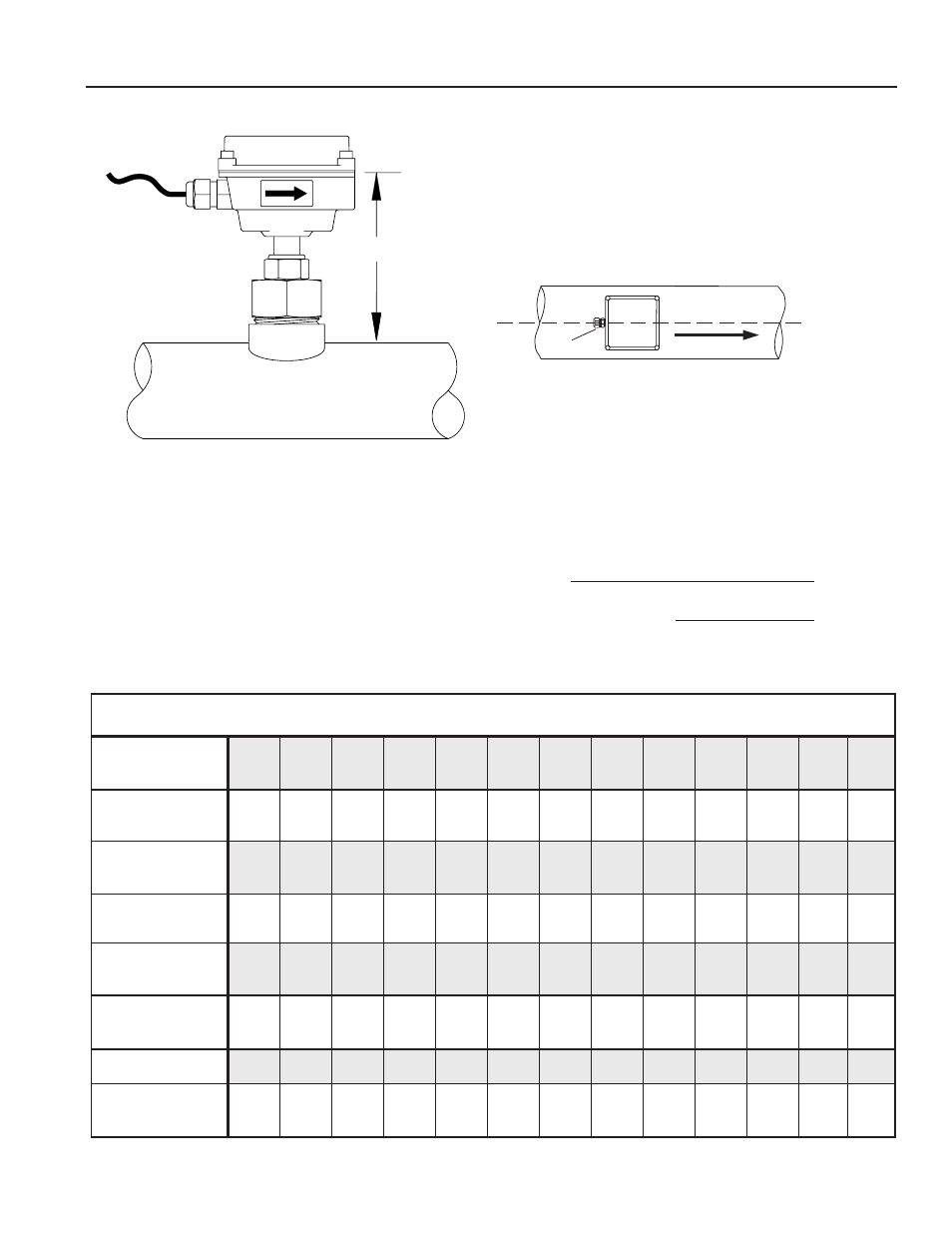

2. Measuring from the outside of the pipe to the joint

in the housing, as shown in the diagram above,

adjust the sensor to Dimension D and hand-tighten

compression nut.

3. Align the conduit housing with the centerline of the

pipe, as shown. Be sure the arrow on the housing

points in the direction of flow.

4. Check Dimension D one more time.

5. Tighten the compression nut fully.

*For pipe sizes larger than 50”, please consult factory.

strain

relief

FLOW

Page 6

INSTALLATION

"D"

TABLE 1: PIPE WALL THICKNESS

PVC/Steel

Sch. 40

PVC/Steel

Sch. 80

Stainless

Steel (10S)

Stainless

Steel (40S)

Copper Tubing

(Type L)

Copper Tubing

(Type K)

Brass Pipe

Duct. Iron

(Class 52)

NOMINAL PIPE SIZE

3”

4”

6”

8”

10”

12”

14”

16”

18”

20”

24”

30”

36”

0.216 0.237 0.280 0.322 0.365 0.406 0.438 0.500 0.562 0.593 0.687

0.300 0.337 0.432 0.500 0.593 0.687 0.750 0.843 0.937 1.031 1.218

0.120 0.120 0.134 0.148 0.165 0.180 0.188 0.188 0.188 0.218 0.250 0.312 0.312

0.216 0.237 0.280 0.322 0.365 0.375 0.375 0.375 0.375 0.375 0.375 0.375 0.375

0.090 0.110 0.140 0.200 0.250 0.280

0.109 0.134 0.192 0.271 0.338 0.405

0.219 0.250 0.250 0.312 0.365 0.375

0.280 0.290 0.310 0.330 0.350 0.370 0.390 0.400 0.410 0.420 0.440 0.470 0.530

RECORD YOUR SETTINGS

Once you have the meter set up and operational, it

is important to record your meter setttings and save

them for future reference.

K-Factor

Insertion Depth (Dim. D)

Proper Depth Setting.

It is important for accuracy that

the sensor be inserted to the correct depth into the pipe.

1. Please visit www.seametrics.com and select the

K-factor Calculator located on the lower left of

the homepage to find dimension 'D' (insertion depth

setting) above.*