Maintenance & troubleshooting, Routine maintenance, Troubleshooting – Precision Control Systems 915 User Manual

Page 19

Page 16 of 21

Maintenance & Troubleshooting

Routine Maintenance

The following bimonthly routine maintenance is suggested.

1. Remove power connection to the system. Lock out power if possible. Carefully vacuum any

dust or dirt collecting within the enclosure. Use caution to not disturb the wiring. Service more

often in dusty locations.

2. Clean the outside of the enclosure with glass cleaner and a soft cotton cloth as necessary.

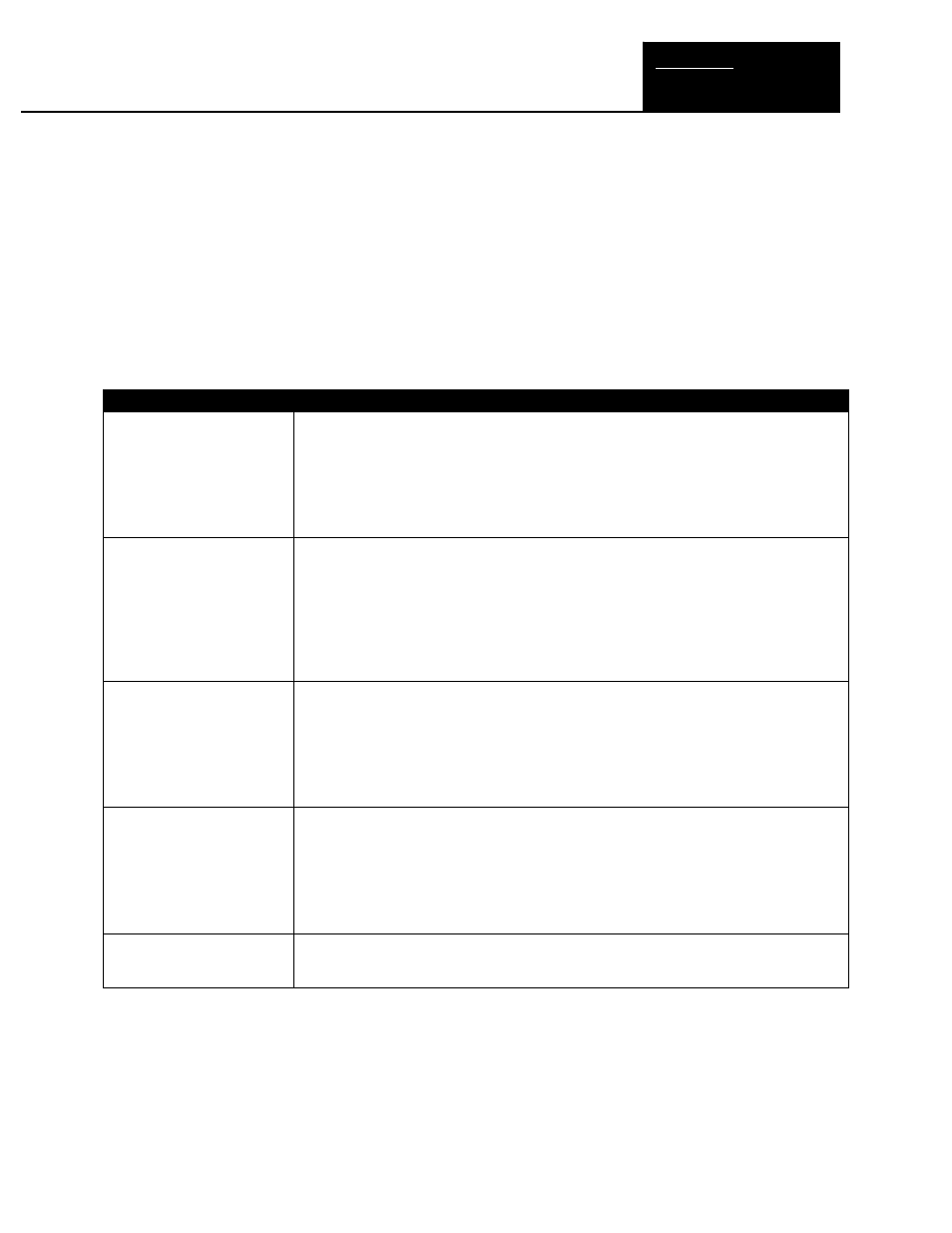

Troubleshooting

Symptom

Action

Heater Contactor will not

energize

1. Verify line voltage is applied to the main disconnect switch.

2. Verify remote heater open, remote process interlocks or water flow

switches (if used) are closed.

3. If not using remote heater enable interlocks or water flow switches,

verify the 2 pin jumpers are installed between TB 100 pins 2 to 3, 10

to 11, and 14 to 15.

4. Check fuses FU 1050, FU 1051, FU 107, FU 108 and TB 100 pin 1.

No output to load,

heaters, or lamps.

Setpoint switch is in

LOCAL mode.

1. Verify a 0-10 VDC signal is present on pins 2 and 3 of the 4-pin

power controller connector. This voltage is proportional to the setting

of the local setpoint potentiometer.

2. Verify that 24 VAC is present on the 2-pin connector of the power

controller.

3. If the COMMAND led on the power controller is not lit and the local

setpoint potentiometer is set greater than 100, refer to the power

controller manual regarding repairs.

No output to load,

heaters, or lamps.

Setpoint switch is in

REMOTE or AUTO.

Operation O.K. with

setpoint switch in

LOCAL.

1. Verify the polarity of the remote input. TB 100 pin 16 is positive, and

17 is negative.

2. Units with Temperature control option: Place temperature controller in

manual mode with 50 percent output. Verify 2.5VDC at TB 100 pins

16 and 17. Refer to the temperature controller manual regarding

repairs.

Full voltage cannot be

obtained.

1. Verify the line voltage. Load voltage maximum is approximately 98

percent of the line voltage.

2. Test in LOCAL setpoint mode. Set the ‘Local Setpoint’ potentiometer

to 900. The voltage should be 108 (120 volt line), 216 (240 volt line),

or 432 (480 volt line). Adjust the SPAN potentiometer of the power

controller as necessary.

3. Refer to the power controller manual regarding repairs.

Load voltage will not go

to zero.

1. Test in LOCAL setpoint mode. Set the ‘Local Setpoint’ potentiometer

to 000 dial divisions. Adjust the zero potentiometer until the voltage is

0 volts.

Section 5