Installation – Precision Control Systems 3629C User Manual

Page 9

MODEL 3629C

5

04/10/2007

INSTALLATION

MOUNTING

The 50 Amp model 3629C controller is convection cooled and must be mounted with the fins aligned vertically on a

flat surface so that air may pass over the fins. Although larger model 3629C controllers are forced air cooled, it is

recommended that all controllers be mounted vertically with power terminals on top.

Allow at least 3" of space

between controllers for air to enter and exit. The controller should be protected from dust and dirt, and must

be located in an environment that does not exceed 55°C.

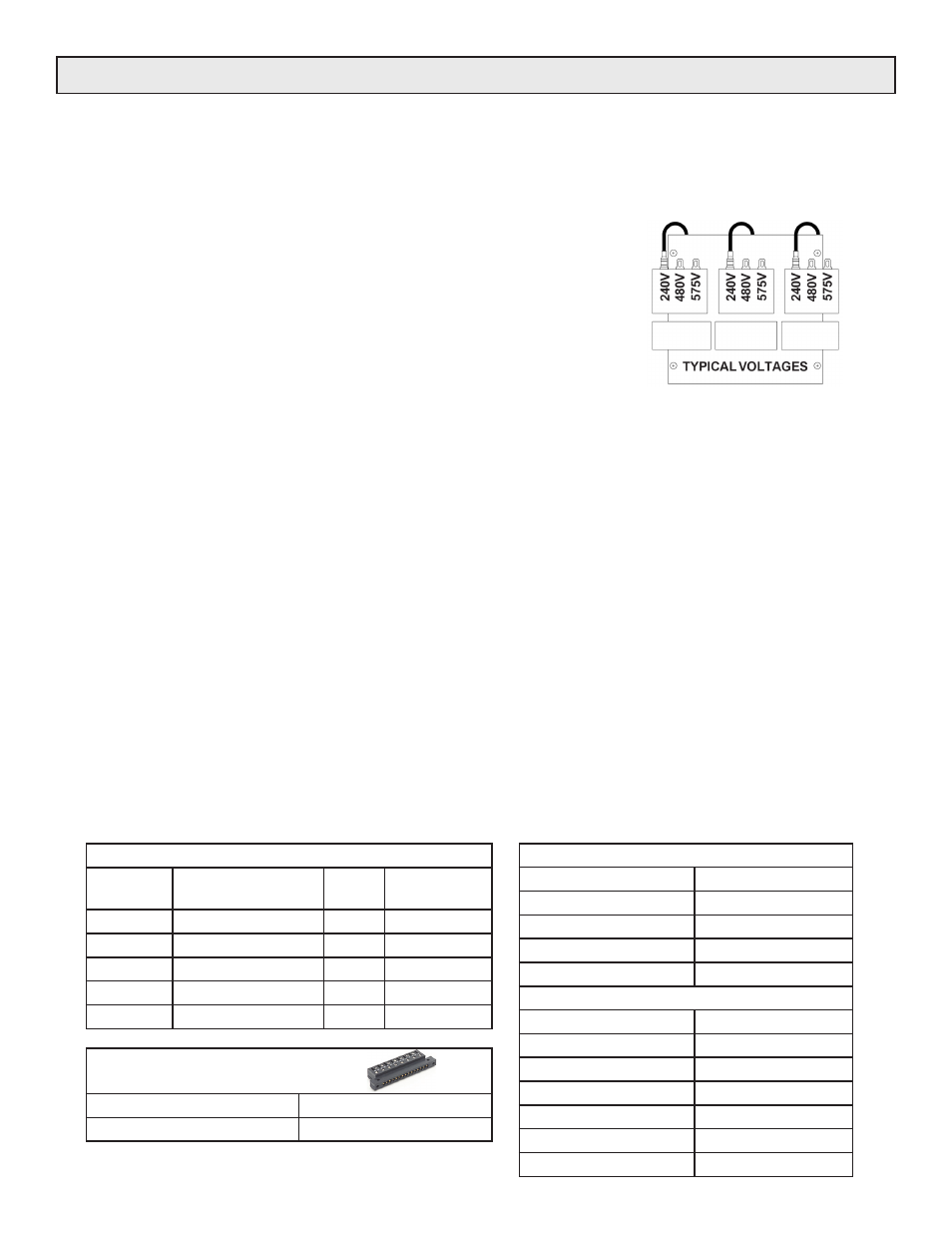

TRANSFORMER TAPS

If the line voltage input is to be changed, place the three fasten connectors

on the transformer taps to correspond with the voltage to be applied.

NOTE: The transformer may fail if all three of the connections to the taps

are not correctly placed. All fasten connectors must be moved to the same

corresponding voltage tab on each phase as shown in the sample illustration.

POWER CONNECTIONS

The line and load connectors on the various sizes of controllers are rated for use with copper conductors with 90°C or

higher insulation. The ratings are calculated for use in a 55°C ambient environment. Multiple connectors are provided

in larger controllers to use parallel conductors in each line and load. See

for the 'inline' and

'inside delta' line and load connections.

STARTUP

Before applying power, determine that the transformer taps are in the correct positions, that the power and load wiring

is correct, and electrical connections are tight. Set the command to zero and apply power to the controller. As the

command signal is increased, the load voltage.

It is recommended that the load and the controller be protected

with the proper rated fuses. See

section.

SCOTT-T TRANSFORMERS

Excessive voltage transients can occur when operating Scott-T transformers with an open or unloaded

secondary. It is recommended that Scott-T transformer be limited to 480 Volts maximum.

DELTA-WYE TRANSFORMERS

It is recommended that a Delta to 4-wire Wye transformer be used to power a 4-wire Wye load. Delta to 3-wire Wye

transformers are acceptable, but Wye to Wye transformers are not suited for use between the controller and load due

to transient conditions which may occur.

WIRE TERMINAL TORQUE RECOMMENDATIONS

TO AVOID FIRE OR DAMAGE TO EQUIPMENT, DETERMINE THAT WIRE CONNECTIONS ARE TIGHTENED TO

THE TORQUE SPECIFICATIONS BELOW AND THE CONNECTION SURFACES ARE FREE OF OXIDATION.

FRAME SIZE 50 & 80 AMPS

WIRE SIZE

INCH-LBS

14 to 10 ga

35

8 ga

40

6 to 4 ga

45

3 to 2 ga

50

FRAME SIZE 120 TO 1000 AMPS

WIRE SIZE

INCH-LBS

6 to 4 ga

100

2 to 1 ga

125

1/0 to 2/0

150

4/0 to 3/0

200

250 to 350 MCM

250

500MCM

300

WIRE LUG INFORMATION

FRAME

SIZE (A)

LUG

CONNECTIONS

LUG

WIRE SIZE

50-80

1 - per LINE/LOAD

USD

#2 - #14

120-160

1 - per LINE/LOAD

CA-6 250MCM - #6

200-425

2 - per LINE/LOAD

CA-6 250MCM - #6

500-750

2 - per LINE/LOAD

CA-7 500MCM - #0

1000

4 - per LINE/LOAD

CA-7 500MCM - #0

R

ECOMMENDED TIGHTENING TORQUE

FOR EDGE CARD CONNECTOR

:

W

IRE

S

IZE

(

AWG

)

T

ORQUE

14

TO

26

GA

4.4 - 5.5

IN

-

LBS