4 module 4 - s, No spsel, 2hys-n – NOSHOK 1950 Series Compact Smart System 5-Digit Process Meter User Manual

Page 10: 0 tof-n, 0 ton-n, Auto rst-n, No enb-2, Hi-ub act-n

Enter the reset action of the output. See figure for details.

Auto

= Automatic action; This action allows the output to automatically reset off

at the trigger points per the Setpoint Action shown in Setpoint Output

Figures. The “on” output may be manually reset (off) immediately by the

front panel

RST

button or user input.The output remains off until the trigger

point is crossed again.

LAtCH

= Latch with immediate reset action; This action latches the output on at

the trigger point per the Setpoint Action shown in Setpoint Output Figures.

Latch means that the output can only be turned off by the front panel

RST

10

6.4 MODULE 4 - S

ETPOINT

O

UTPUT

P

ARAMETERS

(

4-SPt

)

PARAMETER MENU

The Setpoint Output Parameters are only active when an optional output

module is installed in the meter.

Enter the setpoint (output) to be programmed. The

n

in the following

parameters will reflect the chosen setpoint number. After the chosen setpoint

is completely programmed, the display will return to

SPSEL

. Repeat steps for

each setpoint to be programmed. Select

NO

to exit the module. The number of

setpoints available is setpoint output card dependent.

SETPOINT SELECT

SP-2

SP-1

NO

ª

«

NO

SPSEL

ª

«

2

HYS-n

HYSTERESIS VALUE

ª

«

0.0

tOF-n

ª

«

0.0

tON-n

OFF TIME DELAY

ON TIME DELAY

OUTPUT RESET ACTION

LAtCH

Auto

L-dLY

0.0

to

599.9

Sec

0.0

to

599.9

Sec

ª

«

Auto

rSt-n

1

to

59999

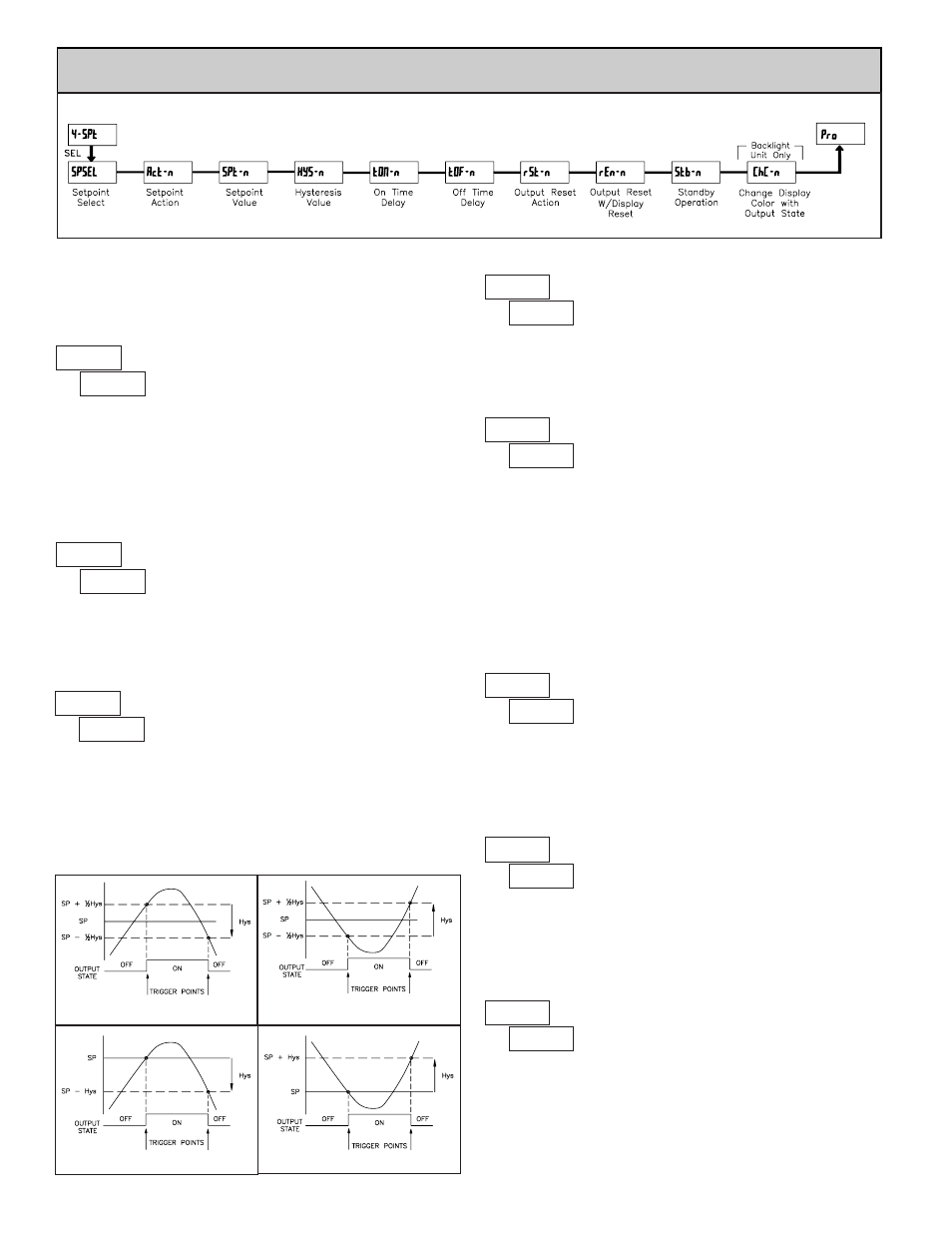

Enter desired hysteresis value. See Setpoint Output Figures for visual

explanation of how setpoint output actions (balanced and unbalanced) are

affected by the hysteresis. When the setpoint is a control output, usually

balanced hysteresis is used. For alarm applications, usually unbalanced

hysteresis is used. For unbalanced hysteresis modes, the hysteresis functions on

the low side for high acting setpoints and functions on the high side for low

acting setpoints.

Note: Hysteresis eliminates output chatter at the switch point, while time delay

can be used to prevent false triggering during process transient events.

Enter the time value in seconds that the output is delayed from turning on

after the trigger point is reached. A value of 0.0 allows the meter to update the

output status per the response time listed in the Specifications.

Enter the time value in seconds that the output is delayed from turning off

after the trigger point is reached. A value of 0.0 allows the meter to update the

output status per the response time listed in the Specifications.

Select

YES

to enable Setpoint 2 and access the setup parameters. If

NO

is

selected, the unit returns to

SPSEL

and setpoint 2 is disabled.

SETPOINT 2 ENABLE

NO

YES

ª

«

NO

Enb-2

Enter the action for the selected setpoint (output). See Setpoint Output

Figures for a visual detail of each action.

SETPOINT ACTION

ª

«

HI-Ub

Act-n

LO-Ub

HI-Ub

LO-bL

HI-bL

LO-Ub

=

HI-Ub

=

LO-bL

=

HI-bL

=

Low Acting, with unbalanced hysteresis

High Acting, with unbalanced hysteresis

Low Acting, with balanced hysteresis

High Acting, with balanced hysteresis

High Acting (Balanced Hys) =

HI-bL

Low Acting (Unbalanced Hys) =

LO-Ub

Low Acting (Balanced Hys) =

LO-bL

High Acting (Unbalanced Hys) =

HI-Ub

SETPOINT VALUE

Enter the desired setpoint value. The decimal point position for the setpoint

and hysteresis values follow the selection set in Module 1.

-19999

to

99999

ª

«

10000

SPt-n