NOSHOK 2000 Series Smart System NEMA 4/IP65 2000 Smart System Enclosure User Manual

Technical manual, Noshok, Enclosures

TECHNICAL MANUAL

2000ENCTM-09

NOSHOK

2000-5000

ENCLOSURES

Corporate Headquarters

1010 West Bagley Road

Berea, Ohio 44017

Ph: 440.243.0888

Fax: 440.243.3472

E-mail: [email protected]

Web: www.noshok.com

INCORPORATED

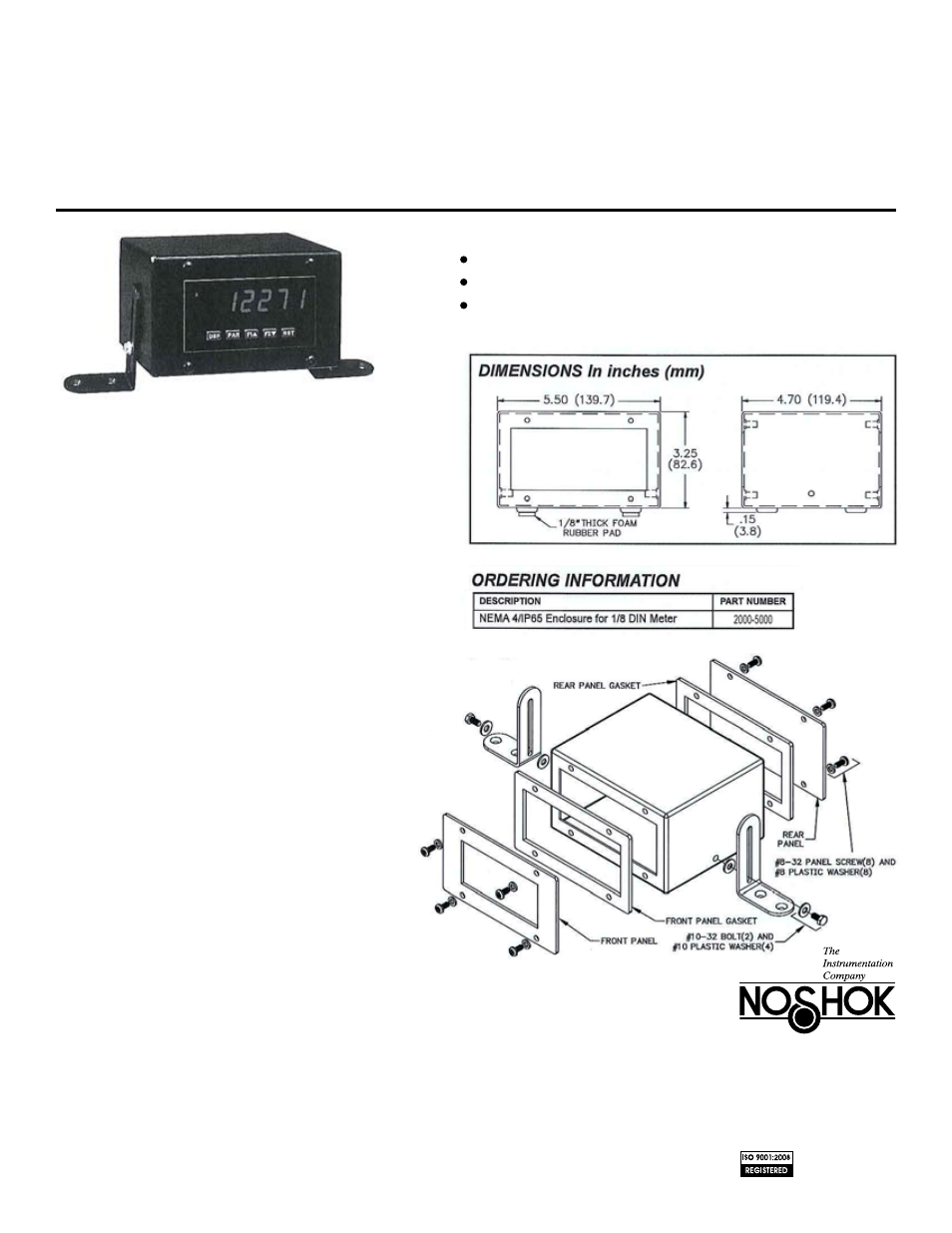

DESCRIPTION

The NOSHOK 2000-5000 Enclosure is fabricated of formed steel with all

seams welded to withstand NEMA 4/IP5 wash-down applications. The kit is

coated with a durable flat black polyurethane finish.

Electrical connections to the enclosed instrument are easily made through

a removable access panel at the rear of the enclosure. The panel must be

drilled to accept conduit fittings or other types of wiring connectors.

The enclosure can be used free-standing or securely fastened to a

mounting surface with brackets which are provided with each enclosure.

The brackets also allow the enclosure to be raised and/or tilted from the

mounting surface in order to achieve the most favorable operating position.

Self-stick rubber pads are provided which can be applied to the bottom of

the enclosure. These rubber pads will protect the mounting surface and are

particularly useful for free-standing installations.

2000-5000 INSTALLATION

1. Mark the location on the rear panel for your wire connector or conduit

fitting, and drill the necessary hole. Connect your wire connector or

fitting to the rear panel.

2. Remove the center sections of the front and rear panel gaskets.

These centers contain the optional foam rubber feet for the

enclosure.

3. Apply the adhesive side of the panel gasket to the front and rear

openings of the enclosure. DO NOT APPLY THE ADHESIVE SIDE

OF THE GASKET TO THE FRONT OR REAR PANELS.

4. Install the unit to the front panel according to the standard panel

installation instructions found in the product literature.

5. Route the wires to be connected to the unit from the conduit fitting

through the rear of the enclosure and out the front.

6. Connect the necessary wires to the unit for the application desired.

7. Attach the front and rear panels to the enclosure with the screws and washers

provided. Alternately tighten each screw to ensure uniform gasket compression.

Visually inspect the sponge rubber gasket. The gasket should be compressed to about

75 to 80% of its original thickness.

8. For a free-standing enclosure, apply the self-stick foam rubber pads to the features on

the bottom of the enclosure to protect the mounting surface.

9. To securely mount the enclosure, attach the adjustable mounting brackets to the enclosure using the

washers and bolts provided. Secure the mounting brackets to the desired mounting location. The

mounting screws to attach the brackets to your surface are not provided due to the variety

of installation options available.

RUGGED STEEL CONSTRUCTION

COMPLETELY SEALED FOR NEMA 4/IP65 WASH DOWN

VERSATILE MOUNTING OPTIONS FOR MACHINE OR DESKTOP