KROHNE ALTOFLUX M 900 EN User Manual

Page 7

Installation and operating instruction ALTOFLUX M900 and 3080 K

7

5

Installation in the pipeline

• Installation material not included, to be provided by customer (stud bolts,

nuts, gaskets, etc.)

• Pipe flanges and operating pressure: refer to tables on “limits” in Section 11.

• Distance between pipe flanges

see fitting dimension “a”, in Section 10 “Dimensions and weights”.

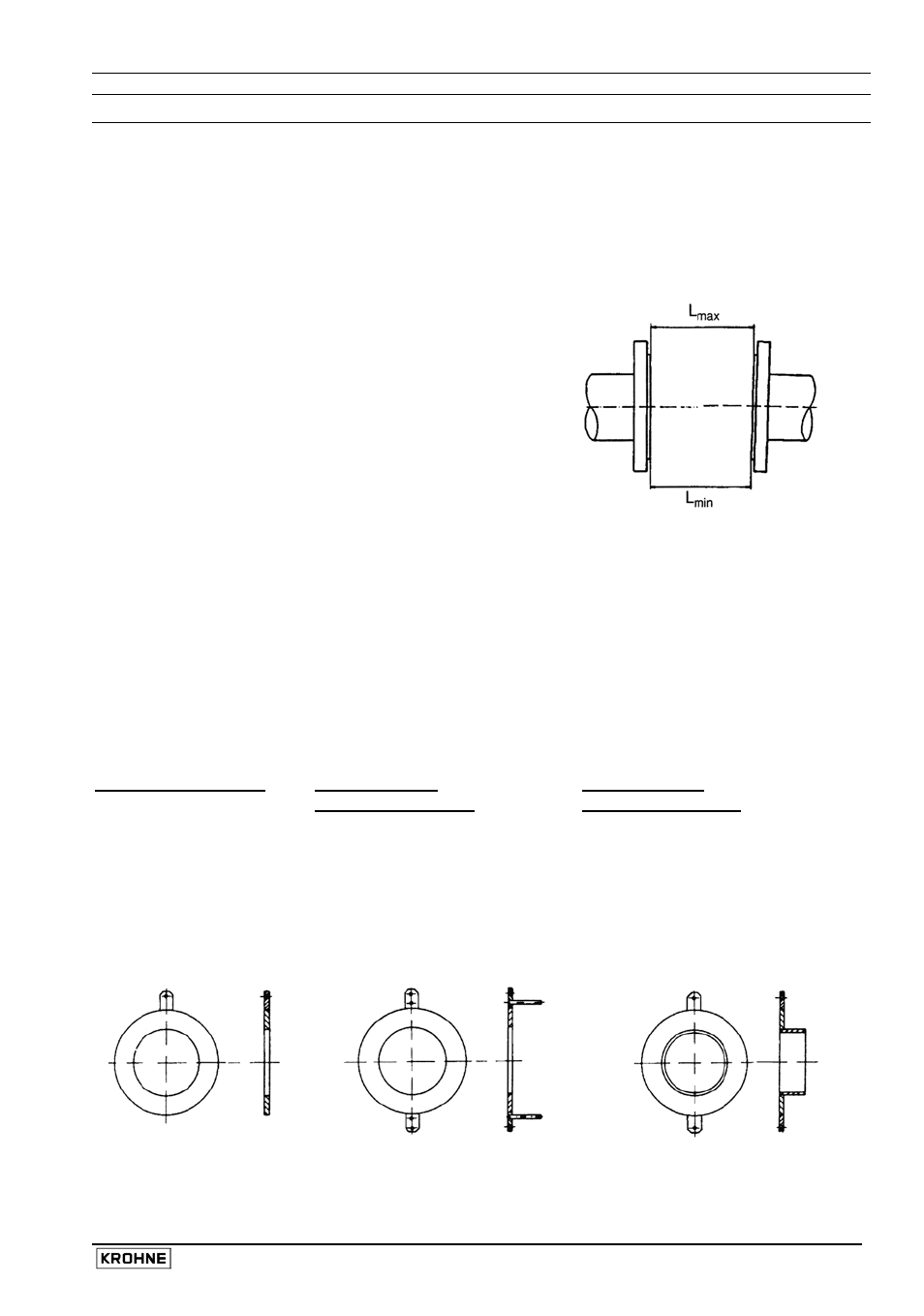

• Position of flanges

Install flowmeter in line with the pipe axis.

Pipe flange faces must be parallel to each other,

max. permissible deviation:

L

max

- L

min

≤ 0.5 mm

L

max

- L

min

≤ 0.02”

• Hard rubber liner

Please note the table on page 4 for temperature

limits of operation, storage and transport.

• Teflon

®

-PTFE liner

Install at the lowest point of the pipe run to avoid an excessive vacuum condition atthe meter.

Do not remove or damage liner, which is formed around the flange edges.

• Gaskets

Use gaskets suitable for the application and appropriate to the liner, not included with

flowmeter, to be provided by customer.

• Grounding rings / protective rings (option)

On plastic pipes and internally coated metal pipelines, grounding rings must form the

conductive connection with the fluid. Refer to Section 7 “Grounding for electrical connection.

Grounding ring, No. 1 Grounding

ring,

protective ring No. 2

Grounding ring,

protective ring No. 3

3 mm/0.12” thick

for flowmeters with

Teflon

®

-PTFE liner,

solidly fitted to the flanges,

3 mm/0.12” thick

with cylindrical neck, to protect

the liner particularly at the inlet

edge against abrasive products,

3 mm/0.12” thick

Length:

30 mm/1.18”, for

≤ DN 300, ≤ 12“

100 mm/3.94”, for

≥ DN 350, ≥ 14“

Teflon

®

is a registered trademark of Du Pont.