KROHNE ACM 500 EN User Manual

Page 16

ACM 500

02/2013

16

8

Product description

8.1

Range of application

The compact inductive conductivity sensor allows determination of the electrical conductivity of

liquids. The small size of the measuring head allows installation in pipes sized DN40 and higher.

The high-sensitivity resolution of 1 µS/cm together with a fast response time ensures reliable

detection of media even with only minor differences in conductivity (e.g. beer – beer).

8.2 Functional

principle

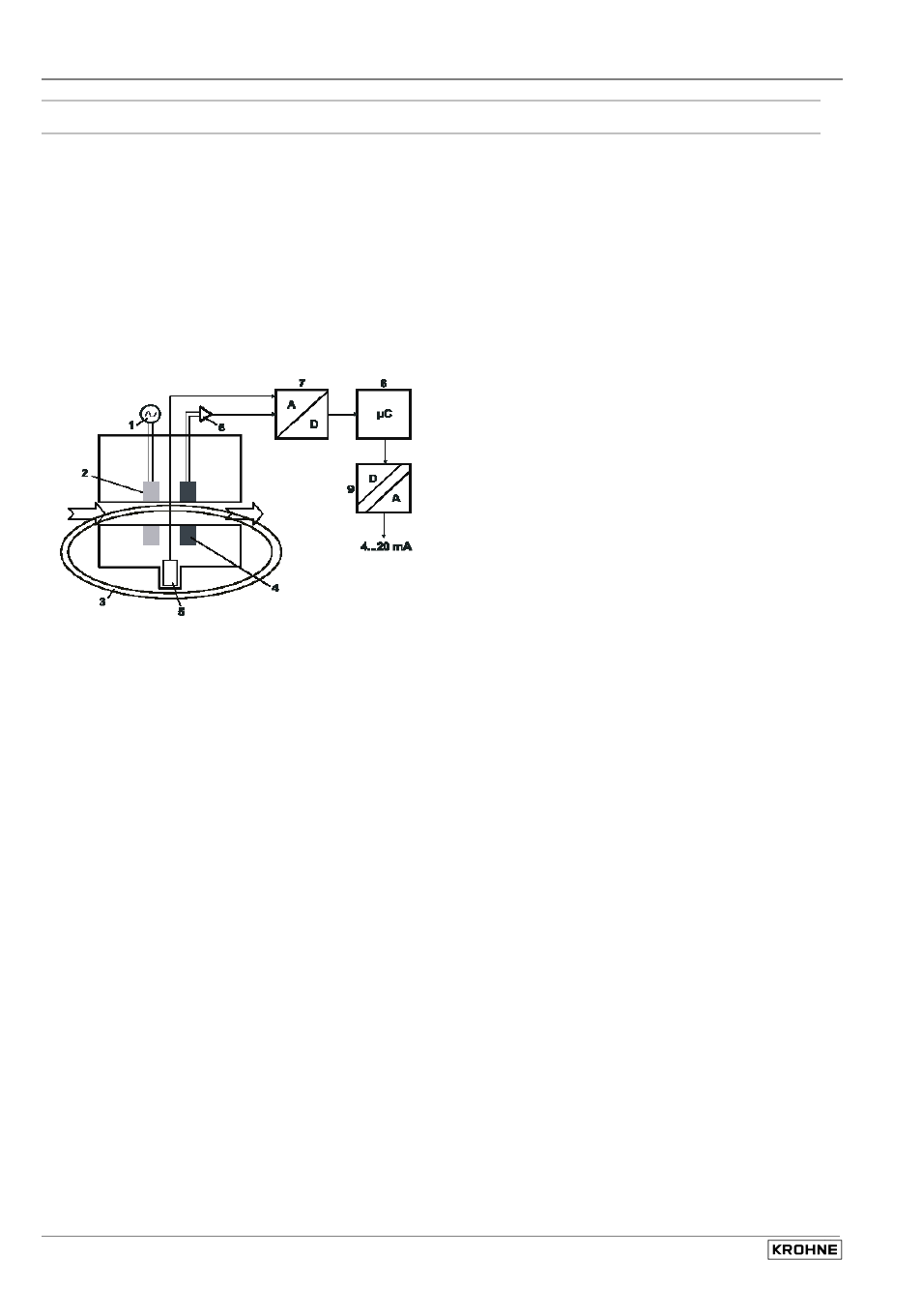

Inductive conductivity measurement is based on the principle of two series-connected toroidal-

core transformers. The primary side of the first transformer (2) is controlled by an AC voltage

generator (1).

The link between the secondary side of the first transformer and the primary side of the second

transformer (4) is formed by the conductor loop, which in turn is formed by the liquid flowing

through the channel bore in the measuring head (3). The better the conductivity of the liquid, the

greater is the measurable current on the secondary side of the second transformer. This signalling

current is processed by a measuring amplifier (6), is digitized (7), further processed by a

microcontroller (8), and forwarded to the digital-to-analogue converter of the galvanically isolated

current output stage (9).

The fast-response precision temperature sensor (5) in the tip of the measuring head is used for

computational compensation of the heavily temperature-dependent conductivity of liquids.

The specially developed signal processing unit (patent applied for) revolutionizes the classic

functional principle and offers you maximum accuracy and reliability.

8.3 Configuration

The associated weldable sleeve of stainless steel ensures installation conforming to hygiene

standards. The evaluation electronics are fully integrated in the stainless steel connection head.

It supplies a 4...20-mA signal, galvanically isolated from supply, for the measured values of

conductivity and temperature. The integrated display unit, together with the jog-shuttle (control

button with turn and touch function), allows simple local assignment of parameters. Measured data

can be read at all times through the viewing window in the screw-down cover.