Installation, 3 mounting – KROHNE OPTIBAR P 2010 C EN User Manual

Page 12

3

INSTALLATION

12

OPTIBAR P 2010 C

www.krohne.com

04/2014 - 4002622502 - MA OPTIBAR P2010C R02 en

3.3 Mounting

3.3.1 Installation steps for connections acc. to DIN 3852

• Ensure that the O-ring is positioned in the slot provided.

• Ensure that the raised face of the receiving part has a smooth surface.

• Screw the device into the thread by hand.

• Devices with wrench flats must be tightened with a wrench. For information on tightening

torque see the following table.

INFORMATION!

•

Handle this highly sensitive electronic measuring device with care, both in and out of the

packaging!

•

Only remove the packaging and any protection cap from the device immediately before

installing to prevent damage to the diaphrahm! Keep the supplied protection cap! Remove the

protection cap slowly and carefully to avoid any negative pressure on the diaphragm.

•

Handle the unprotected diaphragm with extreme care; it is very easily damaged.

•

A device with a gauge reference in the housing (small hole next to the electrical connection)

must be installed so that the gauge reference necessary for measurement is protected from

dirt and moisture. Should the pressure transmitter be exposed to fluid admission, the air

pressure compensation is blocked by the gauge reference. Accurate measurement in this

state is not possible. It can also result in damage to the pressure transmitter.

•

Ensure that no mechanical stress is applied to the pressure port during installation as this

may result in a shift in the characteristic curve. This applies in particular to very small

pressure ranges as well as to devices with plastic pressure ports.

•

With hydraulic systems, arrange the device so that the pressure port faces up (venting).

•

Provide cooling fins when using on steam lines.

CAUTION!

•

Prior to installing the pressure transmitter, it is essential to verify whether the version of the

device on hand completely fulfils the technical and safety requirements of the measuring

point. This applies in particular to the measuring range, overpressure resistance,

temperature, explosion protection and operating voltage.

•

Check the materials used for the wetted parts (e.g. gasket, process connection, separating

diaphragm etc.) for suitability as regards process compatibility.

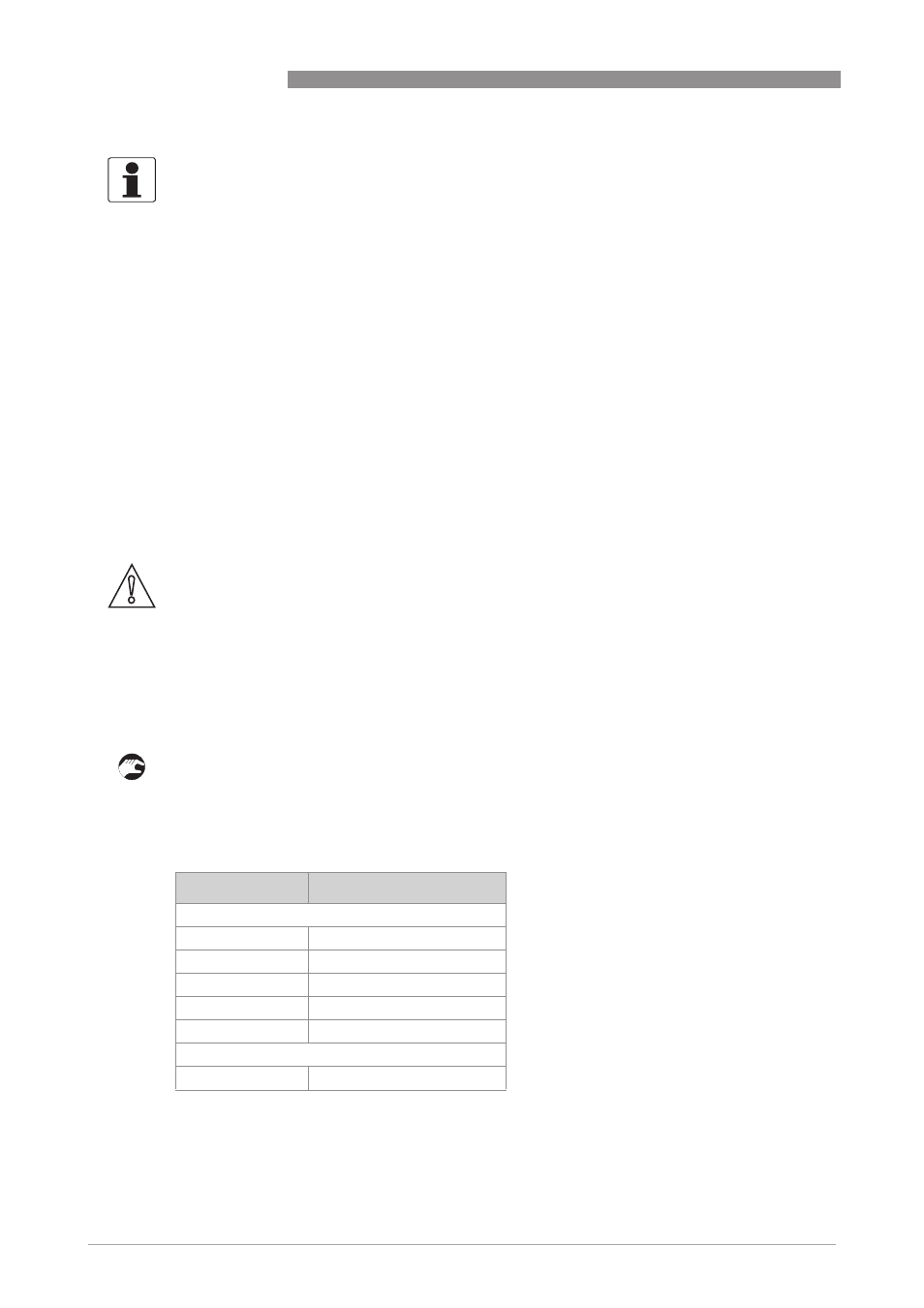

Wrench size

Tightening torque [Nm]

Wrench size of steel

Wrench size of steel

Wrench size of steel

Wrench size of steel

G¼"

approx. 5

G½"

approx. 10

G¾"

approx. 15

G1"

approx. 20

G1½"

approx. 25

Wrench size of plastic

Wrench size of plastic

Wrench size of plastic

Wrench size of plastic

All sizes

max. 3