KROHNE CAPAFLUX IFM 5080 K Datasheet EN User Manual

Page 3

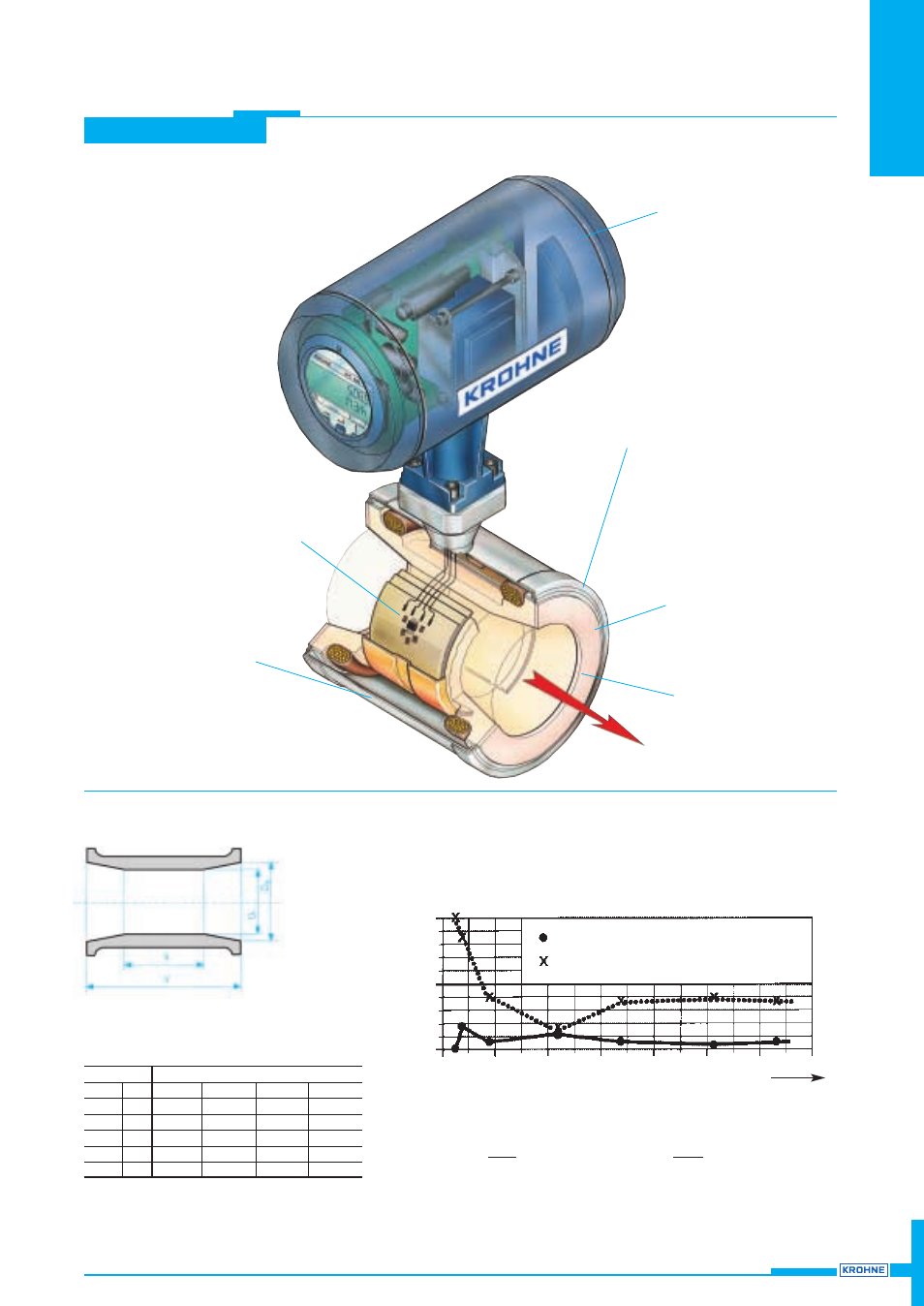

CAPAFLUX

3

CAPAFLUX

Highlights

Capacitive electrodes for

non-contact measurement

Hazardous-duty version,

flameproof enclosure

Self-supporting ceramics

measuring tube,

press-fitted into stainless

steel housing

Meter sizes DN 25 -100 or 1”- 4”

Measuring error

≤ 0.5% of the measured value,

‘sandwich’ design, easy installation,

reliable and safe operation

Electrical conductivity

≥ 0.05µS/cm,

e.g. ultrahigh-purity water, alcohols,

glycerols, glycols, etc.

Dimensionally stable measuring tube,

very good thermal and long-time stability,

no flow, creep and no abrasion,

as is usually the case with plastic liners

No crevices, no blind spots in the

measuring tube, conforms to food

standards, extremely smooth,

surface roughness < 0.8 µm

Design

Flow profile influence

(± SE) as % of measured value

Example for DN 80 (3’’) with quarter bend, straight inlet run

5

× DN (= 400mm = 16’’) from quarter bend to electrode plane

Pressure drop:

∆P = ρ × v

2

(in mbar)

800

ρ = product density in (kg/m

3

)

v = flow velocity in m/s

∆P = ρ × v

2

(in psig)

550

ρ = specific gravity (e.g. water = 1)

v = flow velocity in ft/s

0

0.5

1.0

1.5

2.0

2.5

3.0 [m/s] 3.5

v

0

1.5

3.0

4.5

6.0

7.5

9.0 [ft/s]10.5

CAPAFLUX IFM 5080 K-CAP

Conventional flangeless flowmeter

1.0

± SE

[%]

0.5

0

Meter size

Dimensions in mm (inches)

DN mm

inches D

a

D

i

X

Y

25

1

24 (0.95)

20 (0.79)

26 (1.02)

55 (2.17)

40

1

1

/

2

37 (1.46) 30 (1.18)

36 (1.42)

80 (3.15)

50

2

49 (1.92)

40 (1.57)

51 (2.01) 100 (3.94)

80

3

78 (3.06) 60 (2.36)

70 (2.76) 150 (5.91)

100

4

98 (3.84)

80 (3.15)

103 (4.06) 200 (7.87)