1general, 2technical specifications – KROHNE H250 M9 PROFIBUS PA EN User Manual

Page 2

2

Supplement to Installation and Operating Instructions H 250/ESK3-PA

1

General

This is a supplement to the Installation and Operating Instructions H250 and merely

provides additional information for connecting and operating an ESK3-PA off a

PROFIBUS-PA field bus. The details in these Instructions, especially the safety instructions,

have not been modified by this supplement, and must continue to be observed.

The signal converter ESK3-PA is designed in the context of the modular concept to be

installed exclusively in the M9 display component. Installation and attachment are identical

to the signal converter ESKII (refer to Installation and Operating Instructions H250).

Scope of delivery

In addition to the standard scope of delivery, this supplement, along with a floppy contain-

ing all the available device master files of KROHNE devices, is supplied for the variable area

flowmeter H250/.../M9/ESK3-PA with the PROFIBUS-PA interface.

2

Technical specifications

PROFIBUS-DP, bis 12 Mbit/s

Leitsystem (SPS)

Master Klasse 1

Analog I/O Module

PROFIBUS-PA

4-20 mA

HART Gerät

K RO H N E

1

2

3

4

5

6

PROFIBUS-PA

KR O H NE

1

2

3

4

5

6

Segment-

koppler/Link

Bediensystem

Master Klasse 2

1 000

9 00

8 00

7 00

6 00

5 00

4 00

3 00

2 00

k g/h

1 00

R P

K R O H N E

H2 50

S N

5 86 6 7 7 / 01 - 0 3

M C

H 250/RR /M9/K2/ES K-Z

C

K25.2

1.4 5 7 1

F

C IV

25 1 . 4 5 7 1

M D

1 9 9 7

C 2H5 0H

D

0 . 93 kg / l

V

2 . 5

m P a . s

T

2 3 . 5

C

P

0 . 4

M P a

F IA 10 25

k g

0

3

6

8

7

2

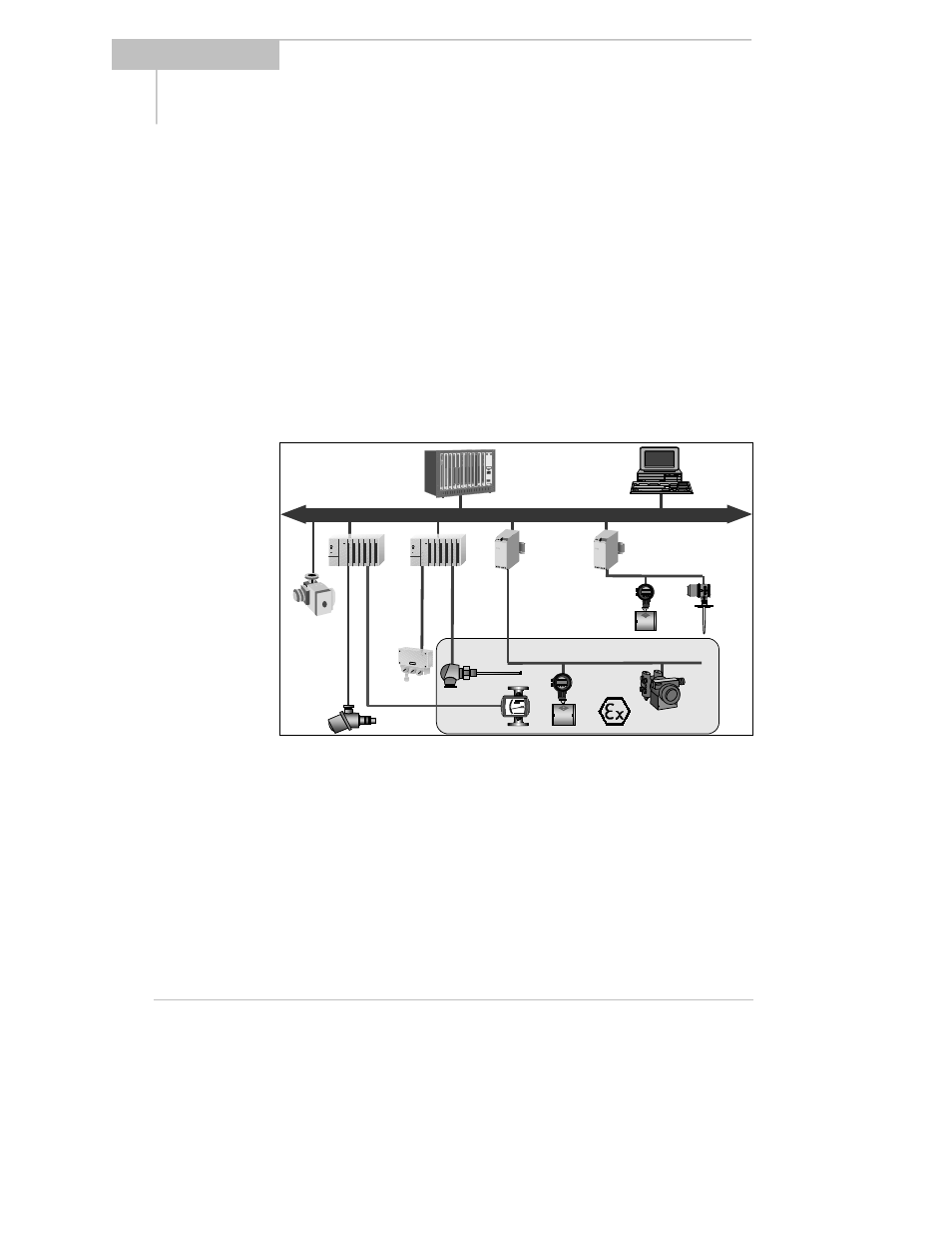

The above illustration shows a typical instrument set-up with PROFIBUS-PA devices in

the hazardous and non-hazardous areas, as well as the connection of conventional non-

PROFIBUS devices.

The PROFIBUS-PA is usually connected to a segment coupler which, among other duties,

performs the conversion to the PROFIBUS-DP. Special care should be taken to ensure that

the segment coupler on the DP side is normally set to a defined baud rate.

You can find more information about planning and operating PROFIBUS-PA networks in the

KROHNE brochure entitled “PROFIBUS-PA Networks”.

Operating system

Master Class 2

PLC

Master Class 1

Analog I/O Modules

Segment

coupler/Link

HART device

PROFIBUS-DP, up to 12 Mbit/s