Detcon TP-624C User Manual

Page 8

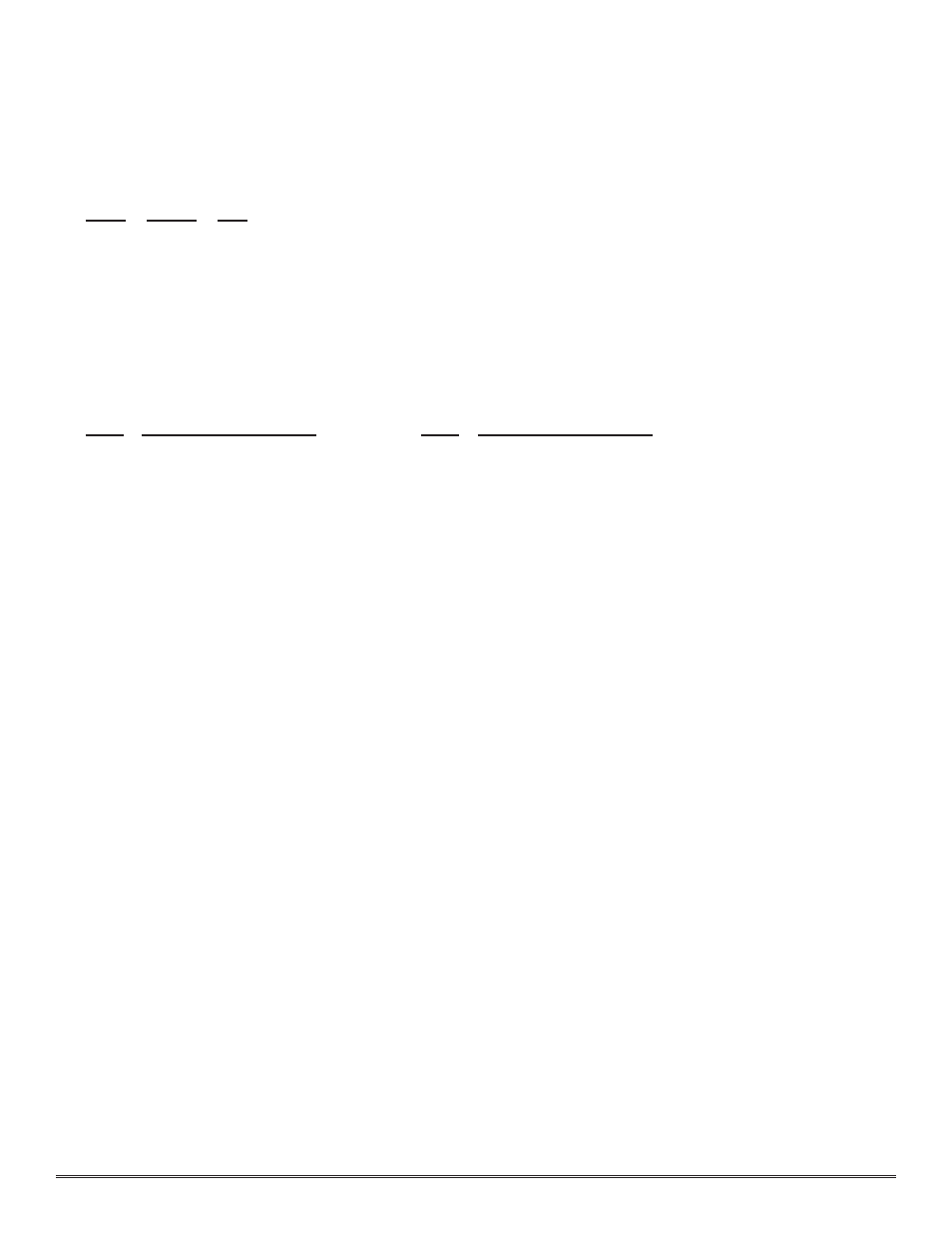

3.5.1 Field Wiring Table (4-20 mA output)

Detcon Model TP-624C solid state H2S sensor assemblies require three conductor connection between power sup-

plies and host electronic controllers. Wiring designators are + (DC), – (DC) , and mA (sensor signal). Maximum

single conductor resistance between sensor and controller is 10 ohms. Maximum wire size for termination in the

sensor assembly terminal board is 14 gauge.

AWG

Meters

Feet

20

240

800

18

360

1200

16

600

2000

14

900

3000

Note 1: This wiring table is based on stranded tinned copper wire and is designed to serve as a reference only.

Note 2:

Shielded cable may be required in installations where cable trays or conduit runs include high voltage

lines or other sources of induced interference.

Note 3:

The supply of power must be from an isolating source with over-current protection as follows:

AWG

Over-current Protection

AWG

Over-current Protection

22

3A

16

10A

20

5A

14

20A

18

7A

12

25A

The RS-485 (if applicable) requires 24 gauge, two conductor, shielded, twisted pair cable between sensor and host

PC. Use Belden part number 9841. Two sets of terminals are located on the connector board to facilitate serial loop

wiring from sensor to sensor. Wiring designators are A & B (IN) and A & B (OUT).

3.5.2 Sensor Location

Selection of sensor location is critical to the overall safe performance of the product. Five factors play an important

role in selection of sensor locations:

(1) Density of the gas to be detected

(2) Most probable leak sources within the industrial process

(3) Ventilation or prevailing wind conditions

(4) Personnel exposure

(5) Maintenance access

Density - Placement of sensors relative to the density of the target gas is such that sensors for the detection of

heavier than air gases should be located within 4 feet of grade as these heavy gases will tend to settle in low lying

areas. For gases lighter than air, sensor placement should be 4-8 feet above grade in open areas or in pitched areas

of enclosed spaces.

Leak Sources - Most probable leak sources within an industrial process include f langes, valves, and tubing connec-

tions of the sealed type where seals may either fail or wear. Other leak sources are best determined by facility engi-

neers with experience in similar processes.

Ventilation - Normal ventilation or prevailing wind conditions can dictate efficient location of gas sensors in a

manner where the migration of gas clouds is quickly detected.

Personnel Exposure - The undetected migration of gas clouds should not be allowed to approach concentrated per-

sonnel areas such as control rooms, maintenance or warehouse buildings. A more general and applicable thought

toward selecting sensor location is combining leak source and perimeter protection in the best possible configuration.

Maintenance Access

Consideration should be given to easy access by maintenance personnel as well as the consequences of close prox-

imity to contaminants that may foul the sensor prematurely.

Note: In all installations, the sensor element in SS housing points down relative to grade (Fig. 1). Improper sensor

orientation may result in false reading and permanent sensor damage.

Detcon Model TP-624C Hydrogen Sulfide Sensor PG.8