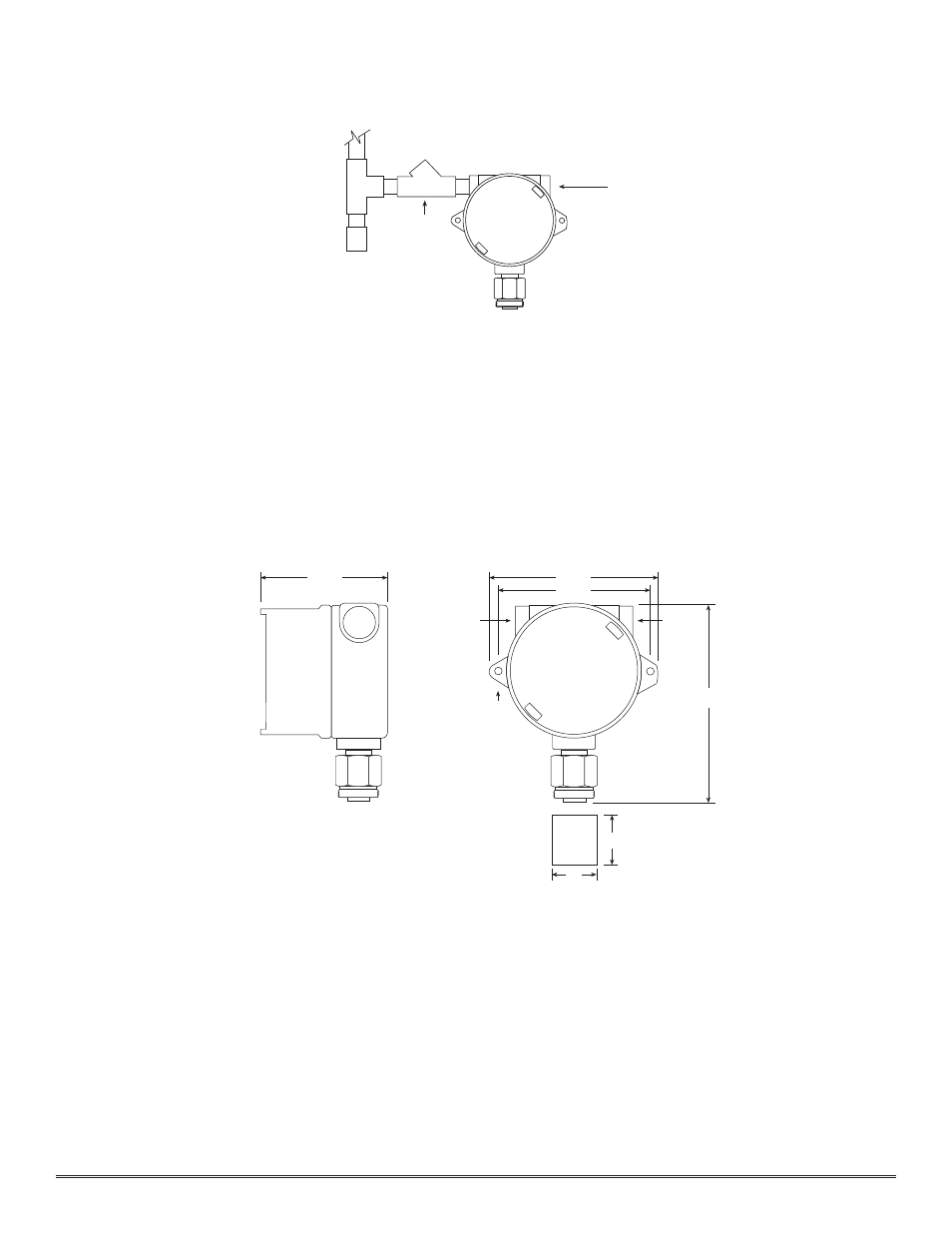

Figure #2, Figure #1 – Detcon FP-524HT User Manual

Page 9

imity to contaminants that may foul the sensor prematurely.

Note: In all installations, the sensor element in SS housing points down relative to grade (Fig. 1). Improper sensor

orientation may result in false reading and premature sensor damage.

3.5.4 Local Electrical Codes

Sensor and transmitter assemblies should be installed in accordance with all local electrical codes. Use appropriate

conduit seals. Drains are required at the bottom of vertical conduit runs. The sensor assemblies are designed to

meet NEC and CSA requirements for Class I; Div. 1; Groups B, C, D, environments.

Note: An appropriate conduit seal must be located within 18" of the sensor assembly. Crouse Hinds type EYS2,

EYD2 or equivalent are suitable for this purpose.

3.5.4 Installation Procedure

a)

Remove the junction box cover and un-plug the control circuit by grasping the two thumb screws and pulling outward.

b)

Securely mount the sensor junction box in accordance with recommended practice. See dimensional drawing (Fig. 2).

c)

Observing correct polarity, terminate 3 conductor field wiring to the sensor base connector board in accordance

with the detail shown in Figure 3.

d)

Use a 3/4 NPT plug to block the unused port.

e)

Replace the plug-in transmitter circuit and replace the junction box cover.

3.5.5 Remote Mounting Applications

Some sensor mounting applications require that the gas sensor head, such as the HT Sensor head to be remotely

mounted away from the sensor transmitter. This is usually true in instances where the gas sensor head must be

mounted in a location that is diff icult to access. Such a location creates problems for maintenance and calibration

activities.

Model FP-524HT Combustible Gas Sensor PG.9

4 3/4"

3/4" NPT

1/4" Dia.

Mounting Holes

7 1/4"

6 1/8"

5 1/2"

3/4" NPT

Rainshield/

Splashguard

2"

2 1/8"

Figure #2

EYS

Seal

Fitting

Drain

“T”

Plug any unused ports.

Figure #1