Styles, Principles of operation, Models – DeFelsko PosiTector 6000 v.3.0 User Manual

Page 2: Power-up / power-down, How to take a measurement, Golden rule, Menu operation, Calibration

The

6000

hand-held, electronic Gage non-destructively

measures the thickness of coatings on metals, quickly and

accurately.

While all

6000

Gages look the same and behave in a

similar fashion, each model has specific abilities or features

as denoted by the model number (e.g. 6000 FNS3). The

model number is engraved on the back and is displayed

when the Gage is turned on.

Styles

Built-In Probe Gages have a permanent, built-in probe for

easy, one-hand operation.

Separate Probe Gages have the probe mounted at the end

of a cable and have an “S” suffix in the model number.

They allow greater accessibility onto small parts or into

hard-to-reach areas. These separate probes retain their

own unique calibration information and are completely

interchangeable. On power-up the

6000

automatically

determines what type of probe is attached, then self-

calibrates.

Principles of Operation

F models use the magnetic principle to measure the

thickness of non-magnetic coatings on ferrous metals.

N models use the eddy current principle to measure the

thickness of non-conductive coatings on non-ferrous

metals.

FN models combine the full abilities of both the “F” and

“N” models.

Models

1 BASIC- mils/microns, FLIPLCD and RESET features.

2 STANDARD- all BASIC features plus average, standard

deviation and user adjustable HiLo limits.

3 MEMORY- all STANDARD features plus storage &

printer/computer downloading for 5000 measurements

Power-up / Power-down

The

6000

powers-up when any button is depressed and

displays the last measurement. Gages with a Built-In probe

turn on automatically when the probe touches the surface.

To preserve battery life, the Gage powers-down after 60

seconds of no activity. There is no OFF button. All settings

are retained during power-down including the last

measurement. Always allow the Gage to power down

automatically before changing the batteries.

How To Take A Measurement

1. On Built-In probe models, slide the probe cover open

FULLY. It acts as a second "foot" to steady the Gage

when required.

2. Press any button to turn the Gage on. Built-In probe

models turn on automatically when the probe is placed

on a surface.

3. Place the probe FLAT on the surface to be measured

and HOLD STEADY. When a valid coating thickness

measurement is calculated, the Gage BEEPS and

BLINKS twice and displays the measurement.

Lift probe AT LEAST 2 INCHES (50 mm) from surface

between measurements - OR - leave probe in the same

location for continuous measurements every 5 seconds.

When finished, slide the Built-In probe cover FULLY shut to

prevent Gage from accidentally turning on and draining the

battery. Keep Separate probes away from metal so they

can power down automatically.

Golden Rule

Measure your uncoated part first! This quick zero-check

determines if any adjustment is needed for your particular

substrate. Zeroing compensates for deviations in shape,

diameter, composition, roughness, etc.

Menu Operation

Gage functions are menu controlled. To access this menu,

turn the Gage on and press

∅⊕ simultaneously to display

the first menu choice.

To answer "YES" press

⊕ and the current choice will be

selected.

To answer "NO" press

∅ and the next option will be

displayed.

After the last MENU option, the Gage re-displays the last

measurement.

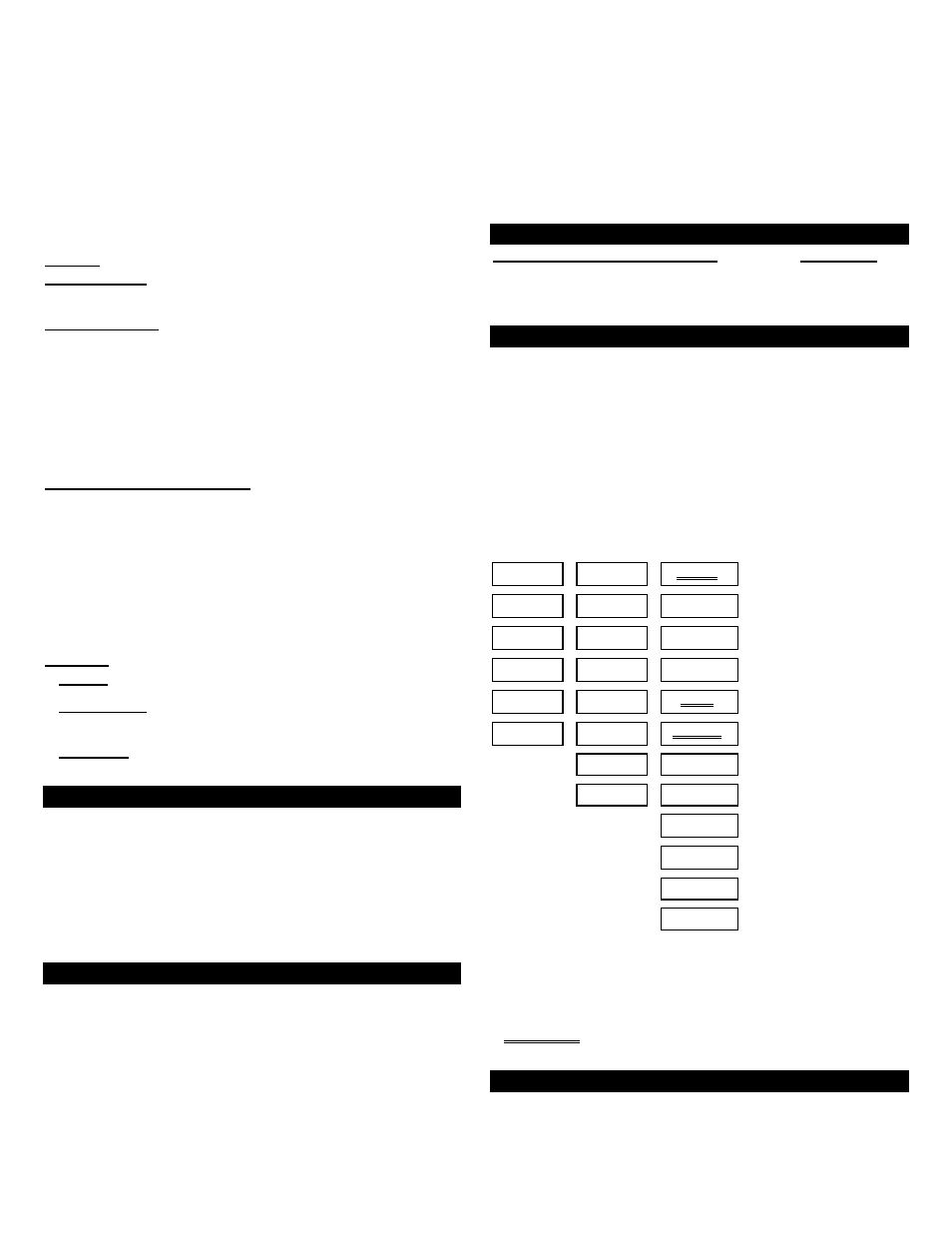

BASIC (1)

Models

STANDARD(2)

Models

MEMORY(3)

Models

ZERO?

STAT

ON?

STAT OFF?

B MARK?

↓

↓

↓

[ 2ND PNT? ]

HiLo

ON?

HiLo OFF?

MEM

ON?

MEM OFF?

↓

↓

↓

N LOCK?

FN AUTO?

ZERO?

STAT ON?

STAT OFF?

↓

↓

↓

MICRONS?

MILS?

[ 2ND PNT? ]

HiLo ON?

HiLo OFF?

↓

↓

↓

FLIPLCD?

N

LOCK?

FN AUTO?

PRINT?

↓

↓

↓

RESET?

MICRONS?

MILS?

CLR MEM?

↓

↓

FLIPLCD?

ZERO?

↓

↓

RESET?

[ 2ND PNT? ]

↓

N LOCK?

FN AUTO?

↓

MICRONS?

MILS?

↓

FLIPLCD?

↓

RESET?

◊ N LOCK/FN AUTO for FN models.

◊ [Bracketed options] appear only on FA & FHS Gages and

microprobes.

◊ ZERO? and 2ND PNT? do not appear in MEMORY,

STATS or HiLo modes.

◊ Underlined options appear only if readings are stored in

memory

Calibration

Calibration is instant and automatic. The 6000 uses

stored N.I.S.T. (National Institute of Standards and

Technology) calibration data and no further calibration is

required. Just ZERO on your uncoated substrate then

measure.