WycoTool Hydraulic Paving Vibrators User Manual

Page 13

11

Wyco Tool Company

CHAPTER 4

SERVICE A D ASSEMBLY I STRUCTIO S

a) Maintenance

interval

It is recommended that Wyco vibrators be

maintained at regular intervals. The

recommended maintenance interval for

vibrators operated between 8,000 VPM and

10,800 VPM is 600 hours. The recommended

maintenance interval for vibrators operated

under 8,000 VPM is 1,200 hours. These

instructions should be followed for

preventative maintenance, which includes

bearing and hydraulic motor seal replacement.

b) Special

Tools

Required

33 inch pipe wrench

2 inch Girth-Grip toothless pipe wrench

(straight vibrators)

3 inch Girth-Grip toothless pipe wrench (angle

vibrators)

Punch Lock clamp set

Tapered guide (used for hydraulic motor seal

installation, Wyco Tool #419754)

Large crescent wrench which opens to

2-3/8"

c) Bearing

replacement

1) Head Housing Removal

See figure 1 or 2 for illustrations of item

numbers listed in parentheses.

Clamp the hydraulic motor housing (13)

in the pipe jaws of a vise. Using a large

crescent wrench, loosen the square head

housing (1) from the motor housing

(right hand threads). Unscrew until the parts

can be easily turned by hand.

2) Rotor

Assembly

Removal

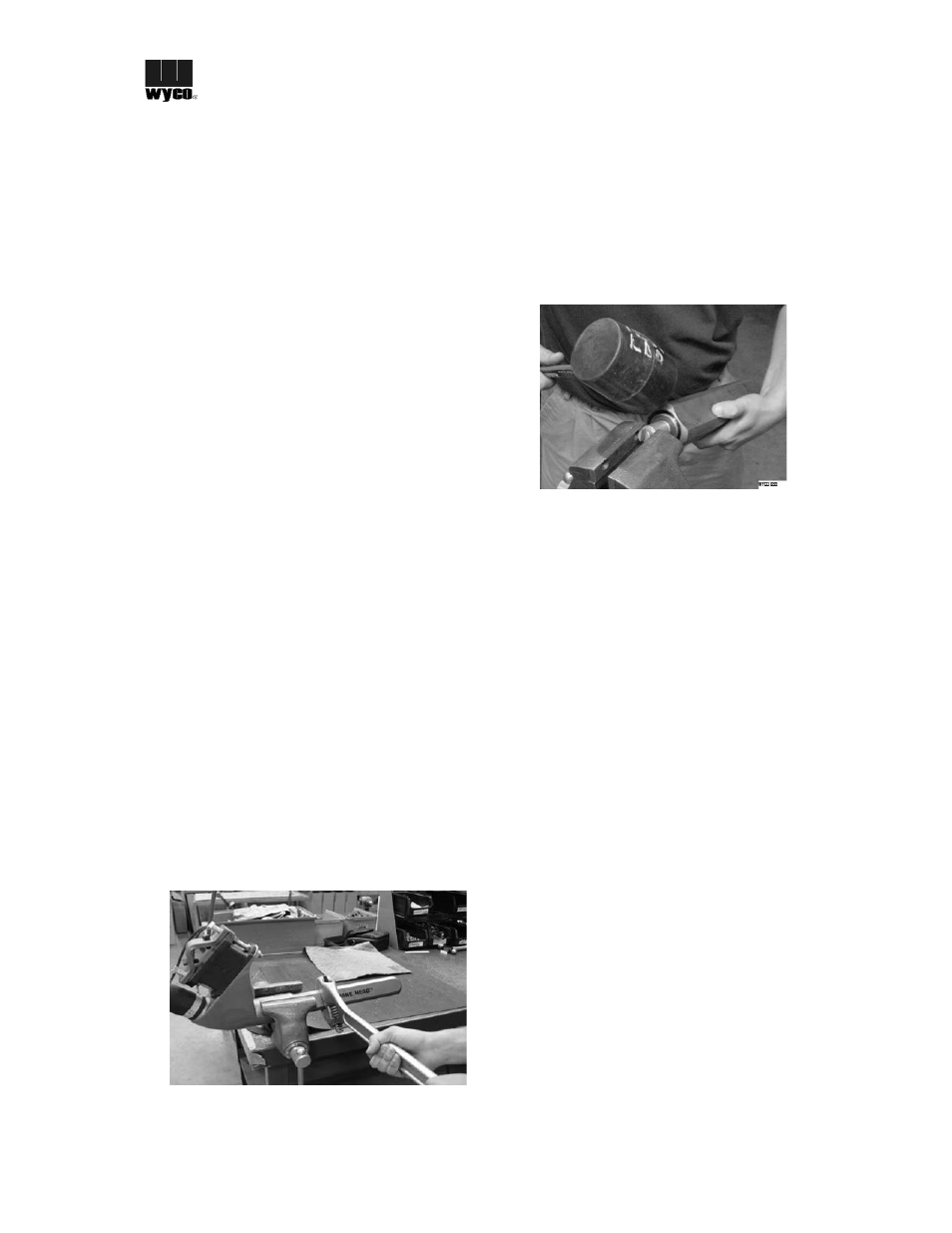

Clamp the flats of the driver sleeve (9) in a

vise. Pull the head housing (1) off of the

rotor assembly.

ote: If there is hydraulic oil in the head,

the seal on the hydraulic motor (14) needs

to be changed as described in Section d.

If the hydraulic motor shaft cannot be turned

by hand, the motor may be locked and may

require replacement, as described is Section e.

If the rotor does not come out by hand it needs

to be tapped off. Tap on the open end of the

square head housing (1) with a rubber

hammer while rotating the housing 90 degrees

every couple of taps. Do not damage the end

of the head housing by hitting it directly with

a hammer. If the rotor is stuck in the housing,

a piece of wood can be used to protect the

head housing threads while using a hammer to

dislodge the rotor assembly.

11