Assembly and adjustments, Continued), Base to column – WEN 4210 10 Variable Speed Drill Press User Manual

Page 10: Table to column

4212

WENPRODUCTS.COM

10

Assembly and adjustments

(continued)

WARNING: If any part is missing or damaged, do not plug the drill press in until the missing or

damaged part is repaired or replaced, and assembly is complete.

The column assembly (column, column support, rack, rack collar, and table support bracket) must be attached to

the base. The table and table support handles must be attached to the table support bracket. The motor housing

must be attached to the column.

Tools needed for assembly

• Adjustable wrench

• Screwdriver

• Hammer and block of wood

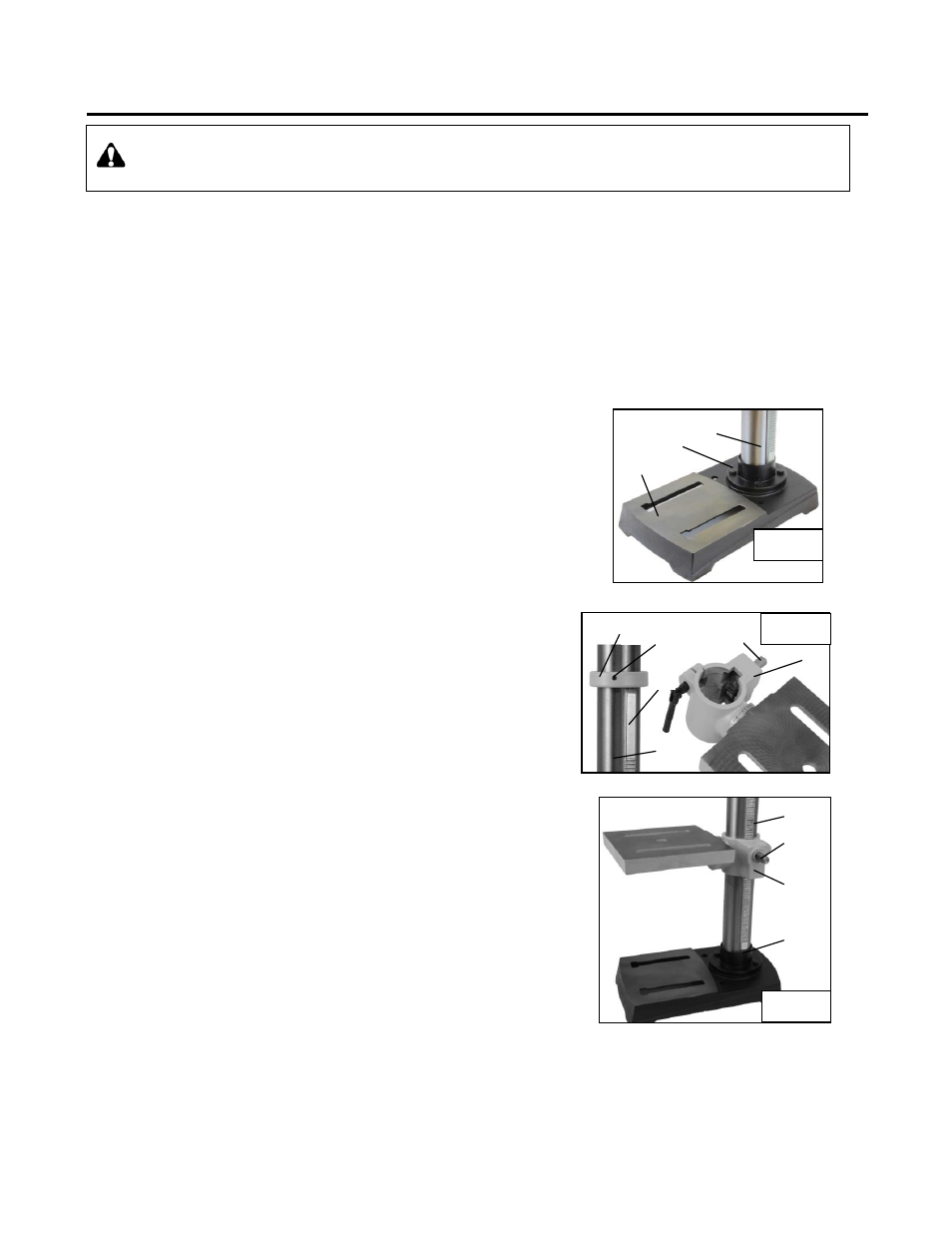

Base to column

(Fig. 2)

1. Set the base (1) on the floor.

2. Place the column tube (2) on the base (1), align the column

support holes with the base holes.

3. Install a bolt (3) in each column support hole and tighten with the

wrench.

Table to column

(Fig. 3–5)

1. Loosen set screw (2) in rack collar (1) and remove the collar.

2. Remove the rack (3) from the column (4).

3. Insert worm shaft (5) into the hole of the table support crank

handle (6) from inside the table support. The worm shaft (5)

should extend outside the housing about 1” (25 mm).

4. Insert the rack (3) into the geared groove of the table support

(6). Make sure the worm shaft (5) on the inside of the table

support is engaged with the teeth of the rack. The table support

should sit at the center of the rack.

5. Slide the table support and rack assembly (3, 5, and 6) down

together onto the column. Insert the bottom edge of the rack

into the lip (7) of the column support. Hold in this position until

step 6 is completed.

6. Place the collar (1) bevel side down over the rack. Tighten the

set screw (2) with the 3 mm Allen wrench to hold the rack in position. (Fig. 3)

1

3

2

Fig. 2

Fig. 3

1

2

3

4

5

6

3

5

6

7

Fig. 4