0 maintenance, 1 maintenance schedule – Seed Hawk GRANULAR AND LIQUID TANKS 2009 User Manual

Page 38

6.0 MAINTENANCE

Seed Hawk Manual

Granular and Liquid Tanks

Page 36

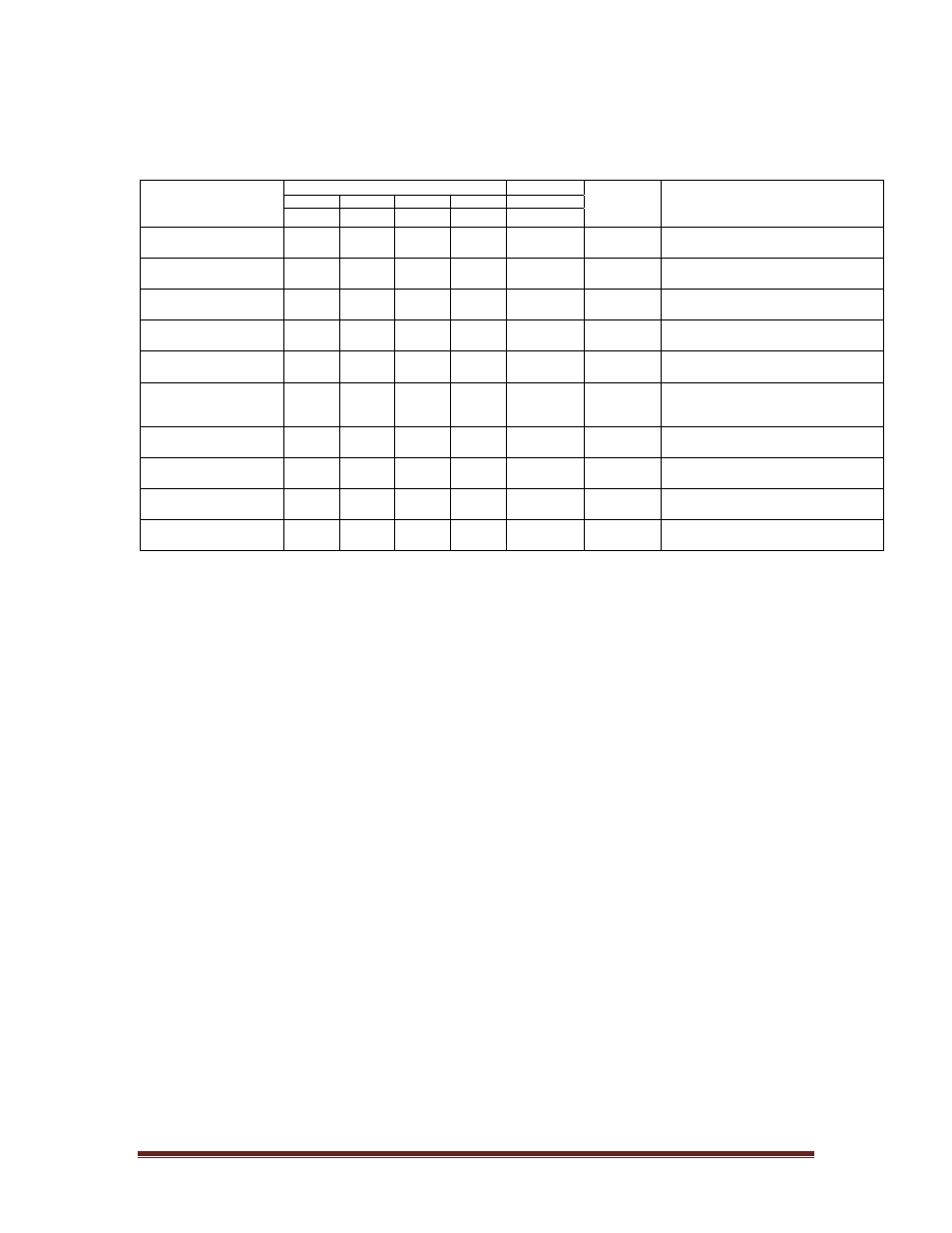

6.1 MAINTENANCE SCHEDULE

Procedure Frequency

check lube clean

change hours

Item

9

6

S

5

Reference Notes

Wheel Hubs

main frame

6

100

100 hr or annually

re-pack bearings or 2 pumps grease

Metering System

sprockets and chains

6

25

25 hr or every 2 days

use dry graphite lubricant

Metering Components

Seed Hawk

®

100

100 hr, or, before seeding, or,

between product changes

Fan System

intake

9

10

10 hr or daily

remove accumulated debris

Fan System

fan blades

9

10

10 hr or daily

must be intact and clean

Fill Auger System

10 in

100

when changing between products,

or,

when stored for long periods of time

Fill Auger System

pillow block bearings

6

10/100

10 hr or daily, and,

100 hr or annually

Fill Auger System

universal joints

6

10/100

10 hr or daily, and,

100 hr or annually

Tank Return Line

open - drain in pail

9

100

at end of seeding season, or,

when stored for long periods of time

Tires

air pressure

9

10

10 hr or daily

inflate to proper pressure

NOTE: The HEX BORE bearings on each Stainless Steel meter are sealed.

DO NOT GREASE THESE BEARINGS.