SANDPIPER ST25A User Manual

Page 3

520-005-000 1/04

Models ST1-A, ST25A Type 4 Page 3

Pumping Diaphragms:

It is recommended that the above procedure be followed to the point of removing

the pumping diaphragm assembly from the pumping unit. Remove eight hex nuts which

allow the outer diaphragm chamber to be lifted from the assembly exposing the PTFE

diaphragm. The PTFE diaphragm can now be lifted from the bolts. The black gasket

(Item 37) is designed to prevent movement and supplement the sealing of the PTFE

diaphragm to retain the driver liquid, and to seal the wetted chamber.

The reassembly should be in reverse as follows.

Install the rubber diaphragm gasket inside the hex head capsrews protruding through

inner chamber. Install PTFE diaphragm in place.

Snug down the outer diaphragm housing (Item 39) evenly torqued on all eight bolts,

alternating from one side to the other in the process. After this subassembly is completed

and reinstalled on the pump as it was removed, the pump should be tested prior to the

reinstallation on the job to make sure the capscrews and nuts are torqued down properly

to prevent leakage around the PTFE diaphragm surfaces. Do not overtighten these bolts.

PTFE has a tendency to cold flow. Torque at 200 inch/pounds (22.59 Newton meters).

A noTe ABoUT Air VAlVe lUBricATion

The SandPiPer pump’s pilot valve and main air valve assemblies are designed

to operate WITHOUT lubrication. This is the preferred mode of operation. There may

be instances of personal preference, or poor quality air supplies when lubrication of

the compressed air supply is required. The pump air system will operate with properly

lubricated compressed air supplies. Proper lubrication of the compressed air supply would

entail the use of an air line lubricator (available from Warren Rupp) set to deliver one drop

of 10 wt., non-detergent oil for every 20 SCFM of air the pump consumed at its point of

operation. Consult the pump’s published Performance Curve to determine this.

It is important to remember to inspect the sleeve and spool set routinely. It should

move back and forth freely. This is most important when the air supply is lubricated. If a

lubricator is used, oil accumulation will, over time, collect any debris from the compressed

air. This can prevent the pump from operating properly.

Water in the compressed air supply can create problems such as icing or freezing

of the exhaust air causing the pump to cycle erratically, or stop operating. This can be

addressed by using a point of use air dryer to supplement a plant’s air drying equipment.

This device will remove excess water from the compressed air supply and alleviate the

icing or freezing problem.

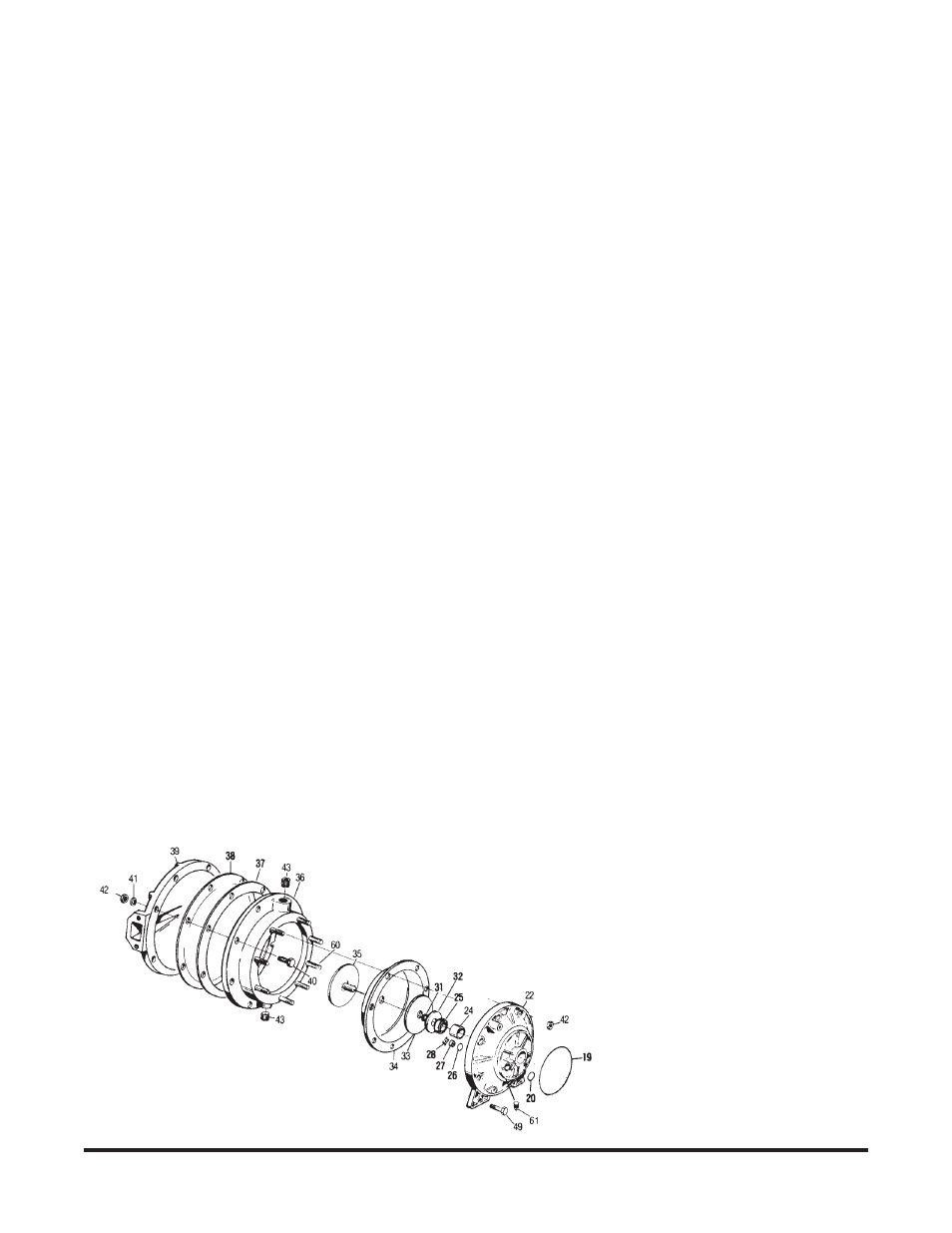

eSADS: eXTernAllY SerViceABle Air

DiSTriBUTion SYSTeM

Please refer to the exploded view drawing and parts list in the Service Manual

supplied with your pump. If you need replacement or additional copies, contact your

local Warren Rupp Distributor, or the Warren Rupp factory Literature Department at the

number shown below. To receive the correct manual, you must specify the MODEL and

TYPE in formation found on the name plate of the pump.