Dimensions: msb1 & msb25 metallic, Materials, Operating temperatures – SANDPIPER MSB25 User Manual

Page 5: Maximum minimum

msb1dl5sm-rev0813

Models MSB1 & MSB25 Page 3

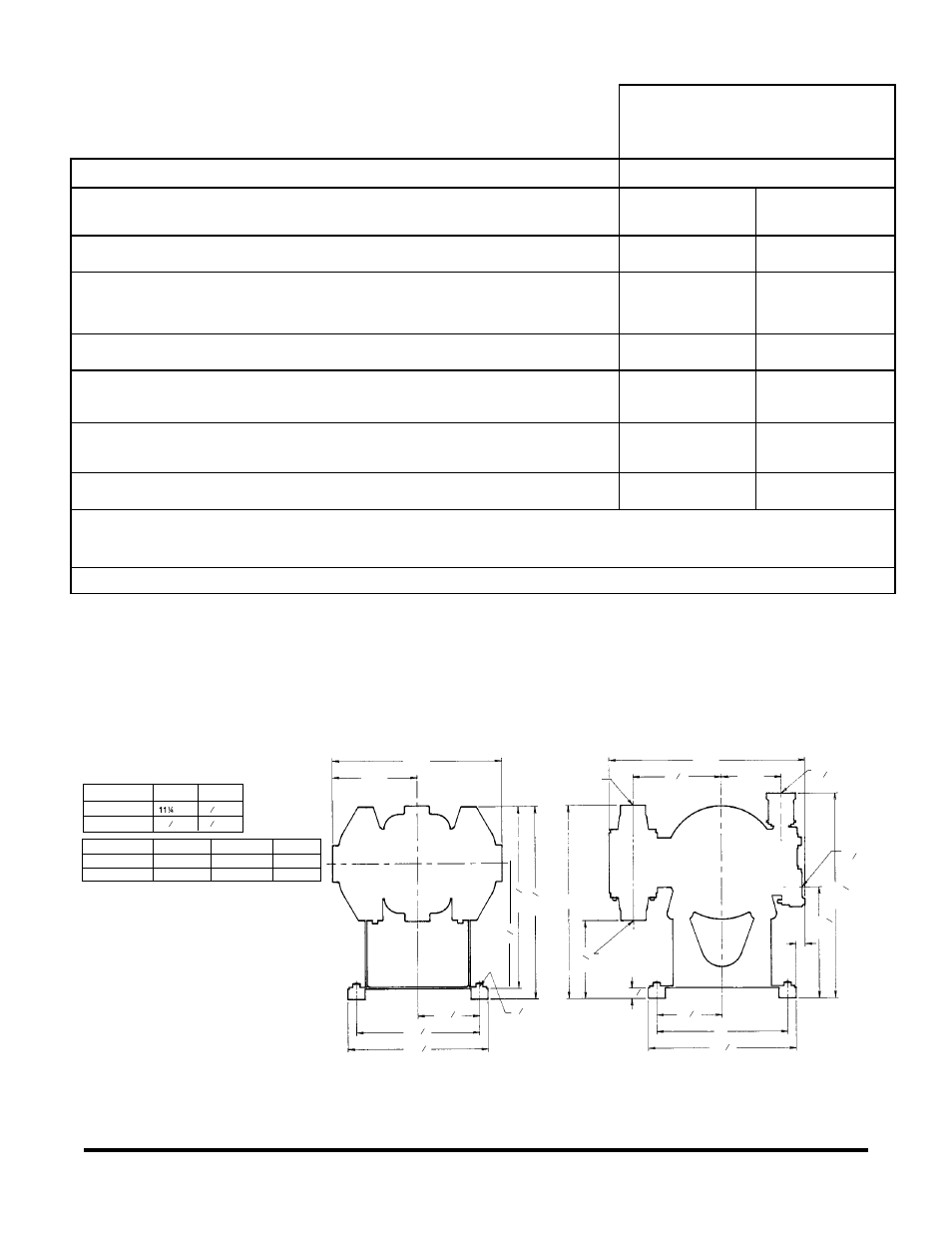

NOTE: UNIT FURNISHED WITH FEET

AS STANDARD. FOR STATIONARY

BOLT DOWN USE, RUBBER FEET CAN

BE REMOVED.

D

AIR INLET

1 2

" NPT(F)

5

7 8

C

(149)

(114)

(229)

9

(260)

AIR EXHAUST

3 4

" NPT(M)

DISCHARGE PORT

1" NPT(F)

1" BSP(F) (25)

SUCTION PORT

1" NPT(F)

1" BSP(F) (25)

11 16

(17)

7

5

8

(194)

E

14

7

16

(367)

(330)

(133)

(333)

13

1

8

12

7

16

(316)

8

9

16

(217)

9 32

" DIA.

MOUNTING HOLES

TYP. (4) PLACES

4

9 32

(109)

8

9 16

(217)

9

3 4

(248)

13

Dimensions are 1/8"

Figures in parenthesis = millimeters

"B"

"A"

Models

"A"

"B"

SST & Alloy "C"

(286)

5

5 8

(143)

All Others

11

3 4

(298)

5

7 8

(149)

Model MSB1 features NPT threaded connections.

Model MSB25 features British Standard Pipe (BSP)

Tapered threaded connections

Dimension C

D

E

Std. Pump

4.3/32" (104) 13.9/32" (337) 5/8" (16)

Pulse Output Kit 4.17/32" (115) 13.23/32" (348) 1.1/16" (27)

4

1 2

10

1 4

5

1

4

*

*16 7/16 With Metal Muffler

MSB1: 1" NPT(F) SUCTION AND DISCHARGE • ½" NPT(F) AIR INLET PORT • ¾" NPT(F) AIR EXHAUST PORT (NOT SHOWN)

MSB25: 1" BSP(F) TAPERED SUCTION AND DISCHARGE • ½" NPT(F) AIR INLET PORT • ¾" NPT(F) AIR EXHAUST PORT (NOT SHOWN)

Dimensions: MSB1 & MSB25 Metallic

Materials

Operating Temperatures

For specific applications, always consult “Chemical Resistance Chart" Technical Bulletin

Nitrile General purpose, oil-resistant. Shows good solvent, oil, water and hydraulic fluid resistance. Should

not be used with highly polar solvents

like acetone and MEK, ozone, chlorinated hydrocarbons and nitro hydrocarbons.

EPDM Shows very good water and chemical resistance. Has poor resistance to oil and solvents, but is fair in

ketones and alcohols.

NEOPRENE All purpose. Resistant to vegetable oils. Generally not affected by moderate chemicals, fats,

greases and many oils and solvents. Generally

attacked by strong oxidizing acids, ketones, esters, nitro hydrocarbons and chlorinated aromatic hydrocar-

bons.

HYTREL

®

Good on acids, bases, amines and glycols at room temperature.

PTFE Chemically inert, virtually impervious. Very few chemicals are known to react chemically with

PTFE: molten alkali metals, turbulent liquid or gaseous fluorine and a few fluoro-chemicals such as

chlorine trifluoride or oxygen difluoride which readily liberate free fluorine at elevated temperatures.

FKM (Fluorocarbon) shows good resistance to a wide range of oils and solvents; especially all aliphatic,

aromatic and halogenated hydrocarbons, acids, animal

and vegetable oils. Hot water or hot aqueous solutions (over 70°F) will attack FKM.

Santoprene

®

Injection molded thermoplastic elastomer with no fabric layer. Long mechanical flex life. Excel-

lent abrasion resistance.

Maximum

Minimum

‡

CF-8M Stainless Steel equal to or exceeding ASTM specification A743 for corrosion resistant iron chro-

mium, iron chromium nickel, and nickel based alloy castings for general applications. Commonly referred

to as 316 Stainless Steel in the pump industry.

190°F

-10°F

88°C

-23°C

280°F

-40°F

138°C

-40°C

200°F

-10°F

93°C

-23°C

220°F

-20°F

104°C

-29°C

220°F

-35°F

104°C

-37°C

350°F

-40°F

177°C

-40°C

275°F

-40°F

135°C

-40°C

Maximum and Minimum Temperatures are the limits for which

these materials can be operated. Temperatures coupled with

pressure affect the longevity of diaphragm pump components.

Maximum life should not be expected at the extreme limits of

the temperature ranges.

ALLOY C CW-12MW equal to or exceeding ASTM A494 specification for nickel and nickel alloy castings.

Materials