Trouble shooting guide, Flush the pump, Caution – SANDPIPER M02 Metallic User Manual

Page 7: Safety, Warning

520-263-000 5/03

Model M02, Metallic Design Level 1 Page 6

FLUSH THE PUMP

This pump was tested with water

containing an oil-based rust inhibitor.

If this solution could contaminate or

react with the fluid you are pumping,

flush the pump thoroughly with a

solvent/detergent to clean internal

components. The solvent/detergent

must be compatible with the pump

materials of construction. Care should

be taken to flush the pump each time

it is disassembled for maintenance or

repair.

CAUTION

Ensure that only the recommended grade

of lubricating oil is used. Marathon

M02 Model Pumps require a SAE 10

lubricating oil. Other grades of oil may

cause the Air Logic System to operate

intermittently, thereby causing a loss

of output and failure to operate.

If the pump accelerates or is running

too fast due to a lack of fluid, then

stop it immediately by shutting off the

air supply. A dry pump will accelerate

to a high speed causing wear to

elastomers.

If the fluid you are pumping tends to dry

up or set when it is not moving, then

flush the pump as often as necessary to

prevent the fluid from drying in the pump.

Drain the pump thoroughly before storing.

If feasible, invert pump to allow any fluid

to drain from the non-return valves.

SAFETY

Your Marathon Pump M02 Model

is a high performance unit capable

of achieving high outputs at high

efficiencies. However, as is common

with pneumatic equipment, the pump

efficiencies is reliant upon the air being

clean, dry and filtered. Failure to comply

with these requirements may lead to

loss of performance and reduced

component life and in extreme cases,

permanent damage to the pump.

To avoid leaks, ensure that all fluid

connections are tight. The use of PTFE

thread tape correctly applied should

ensure 100% leakproof connections.

Failure to ensure 100% sealability

of the suction connection could

adversely affect suction performance.

If you are pumping hazardous fluids,

or operating the pump in an enclosed

area, it is essential that the exhaust

from the pump is piped away to a safe

location. When pumping hazardous

fluids the above instructions must be

adhered to in order to ensure safe

operating procedures. (Under certain

operating conditions the failure of

internal components can lead to the

pumped fluid being exhausted via the

pump exhaust outlet). See Fig. 2.

WARNING

NEVER place your hands over or near the pump suction port.

Powerful suction could cause serious bodily injury.

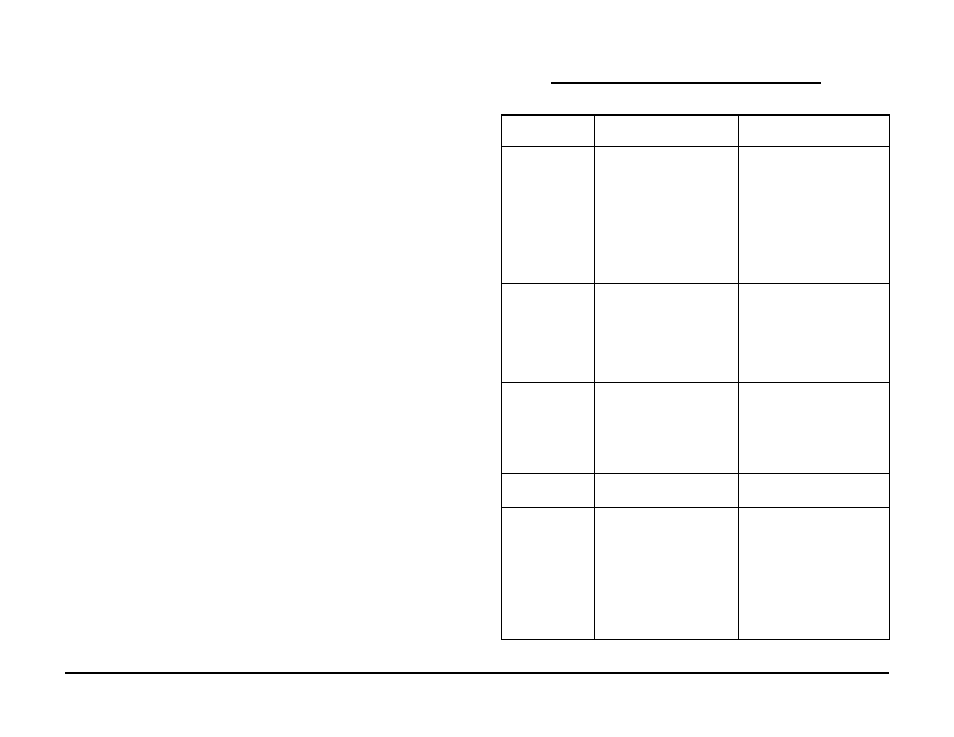

TROUBLE SHOOTING GUIDE

PROBLEM

CAUSE

SOLUTION

Pump will not start

Air valve assembly malfunction/

siezure.

Obstructed fluid line.

Obstructed diaphragm chamber.

Diaphragm failure causing fluid

& excessive air to be expelled

through the exhaust.

Diaphragm seal failure.

Air valve system malfunction.

Check carrier for freedom

of movement. Clean, oil & replace.

Clean line or increase line size.

Remove obstruction.

Replace diaphragm.

Replace shaft seals.

Check all seals in intermediate

bracket.

Erratic flow

Diaphragm failure on one side.

Valve ball not seating.

Suction leakage.

Diaphragm failure causing fluid

& excessive air to be expelled

through the exhaust.

Diaphragm seal failure.

Replace diaphragm.

Check and remove obstruction.

Check and correct.

Replace diaphragm.

Replace shaft seals.

Pump strokes but

will not discharge

Excessive suction lift.

Suction line leakage.

Valve ball not seating correctly

or damaged.

Suction line or strainer clogged.

Diaphragm failure.

Shorten suction line.

Check and correct.

Check and remove obstruction/

replace.

Clear.

Replace diaphragm.

Fluid discharged

from

Diaphragm failure.

Replace diaphragm.

Intermittent stroke

rate

Over lubrication.

Diaphragm rod seal failure.

Air valve system malfunction.

Valve ball not seating/partially

obstructed.

Shut-down pump. Remove air

connection into pump &

introduce a small quantity of

de-greasing agent into air

valve and replace line. Run

pump until clear.

Replace seals.

Check all seals in intermediate

bracket.

Clear obstruction.

NOTE: Check all solutions before dismantling the pump

.