Grounding the pump, Warranty, Warning – SANDPIPER MSA2-C User Manual

Page 7

msa2dl5sm-rev0614

Models MSA2 MSA2-B MSA2-C Page 5

PROBLEM: Pump will not cycle. (Note: Always disconnect air supply to relieve air

pressure before disassembling any portion of pump.)

POSSIBLE CAUSES:

A. Discharge hose or line plugged, or discharge head requirement greater than air

supply pressure. (Disconnect discharge line to check.)

B. Spool in air distribution valve not shifting. (Remove end cap and check spool —

must slide freely.)

C. Diaphragm ruptured. (Air will escape out discharge line in this case.)

D. Blockage in diaphragm chamber preventing movement. (Shut off air supply and

reopen after pressure is relieved.)

PROBLEM: Uneven discharge flow. (Indicates one chamber not operating properly.)

POSSIBLE CAUSES:

A. Check valve not sealing properly in one chamber.

B. Diaphragm failure in one chamber.

C. Air leak at suction manifold joint or elbow flange one side.

For additional information, see the Warren Rupp Troubleshooting Guide.

WARRANTY:

This unit is guaranteed for a period of five years against defective material and

workmanship.

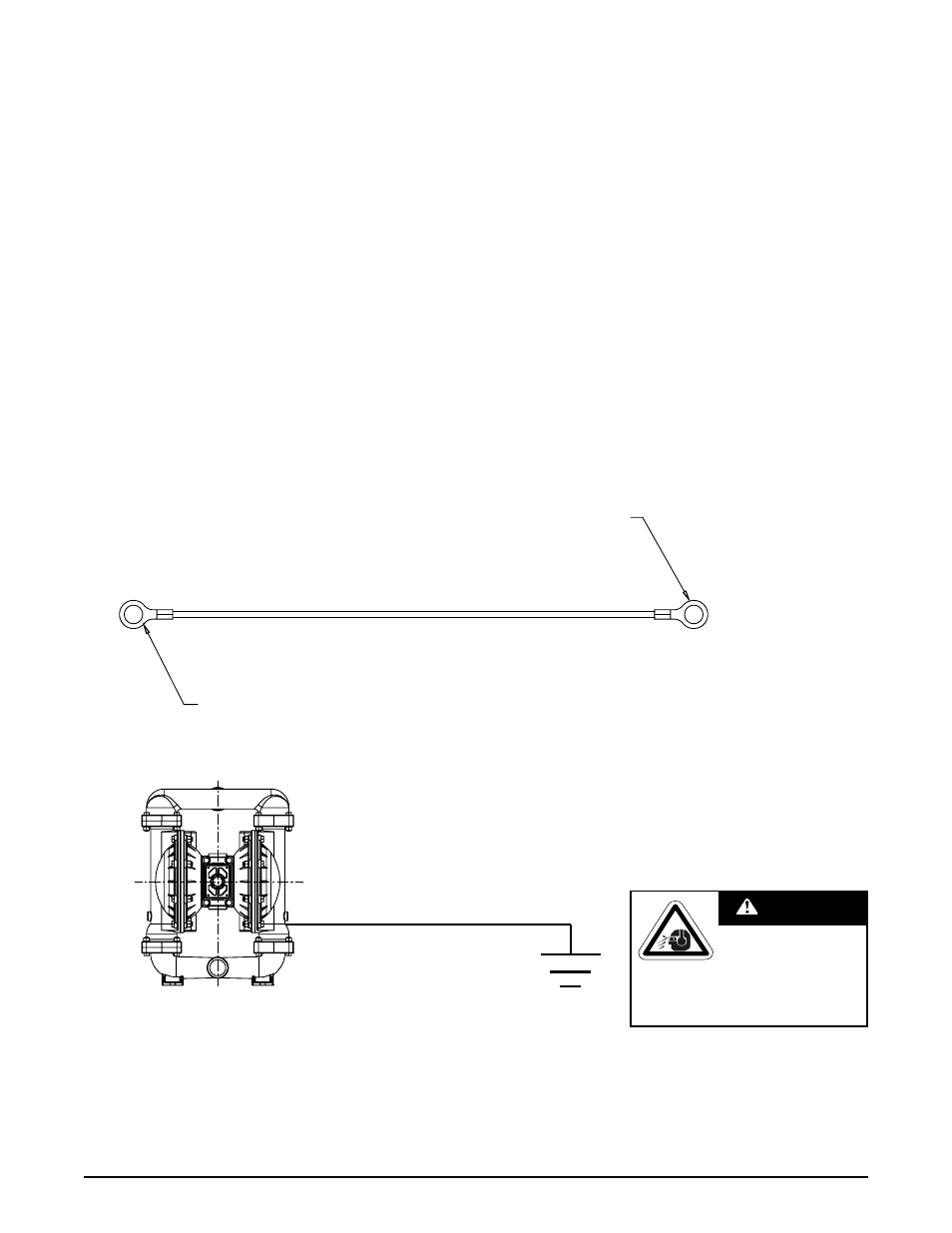

This 8 foot long (244 centimeters)

G r o u n d S t r a p , p a r t n u m b e r

920-025-000, can be ordered as a

service item.

To reduce the risk of static electrical

sparking, this pump must be grounded.

Check the local electrical code for

detailed grounding instruction and the

type of equipment required.

Grounding The Pump

ONE EYELET IS INSTALLED TO A TRUE EARTH GROUND.

(REQUIRES A 5/16 OR 8MM MAXIMUM DIAMETER BOLT)

ONE EYELET IS FASTENED TO THE PUMP HARDWARE.

WARNING

Take action to prevent static

sparking. Fire or explosion

can result, especially when

handling flammable liquids. The pump,

piping, valves, containers or other

miscellaneous equipment must be

grounded.