Check ball valve drawing – SANDPIPER S05 Non-Metallic User Manual

Page 19

s05conductiveacetal-rev0211

Model S05 Conductive Acetal Design Level 2 Page 17

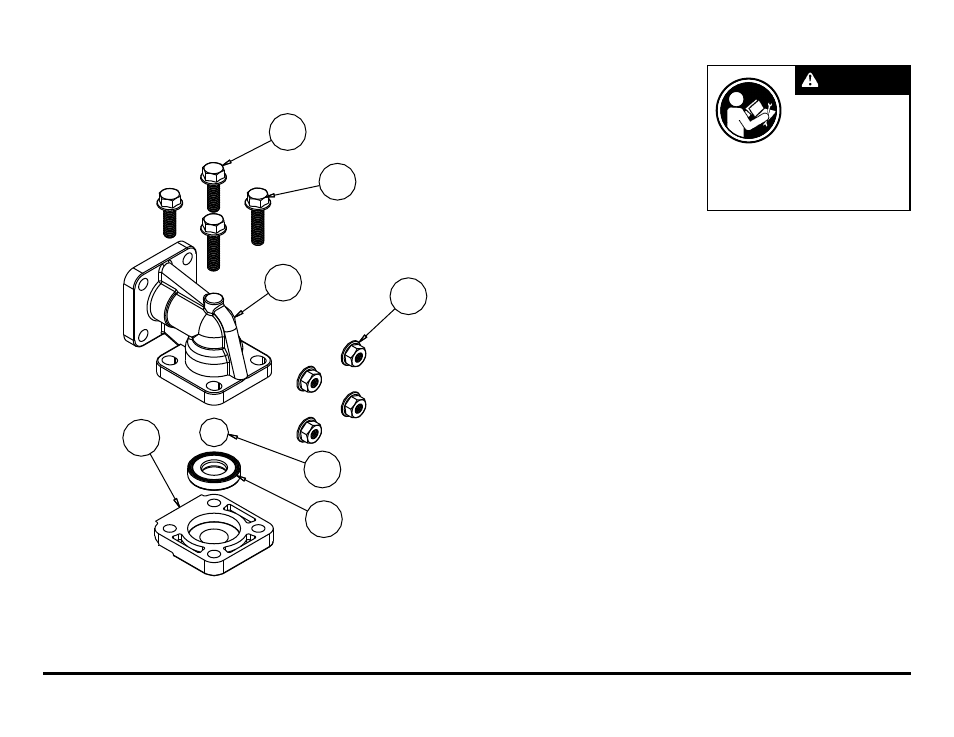

Check Ball Valve Drawing

34

2

25

14

18

10

9

MODULAr CheCk BALL VALVe

SerViCing

Before servicing the check valves,

first shut off the suction line and then

the discharge line to the pump. Next,

shut off the compressed air supply,

bleed air pressure from the pump, and

disconnect the air supply line from

the pump. Drain any remaining fluid

from the pump. The pump can now be

removed for service.

To access the modular check valve,

remove the elbows (items 16 and 17

from pump composite repair parts

drawing). Use a 1/2" wrench or socket

to remove the fasteners. Once the

elbows are removed, the modular check

valves can be seen in the cavities of the

outer chamber (items 13).

Inspect the check balls (items 2) for

wear, abrasion, or cuts on the spherical

surface. The check valve seats (items

33) should be inspected for cuts,

abrasive wear, or embedded material

on the surfaces of both the external

and internal chamfers. The spherical

surface of the check balls must seat

flush to the surface of the inner chamfer

on the check valve seats for the pump to

operate to peak efficiency. Replace any

worn or damaged parts as necessary.

re-ASSeMBLe The CheCk VALVe

Place a check ball (item 2) in the

ball cage of either the discharge elbow

or the outer chamber. Install a check

valve seat in the counter on each end

of the chamber. Refasten the elbows to

the chamber.

Read these instructions

completely, before in-

stallation and start-up.

It is the responsibility of

the purchaser to retain

this manual for reference. Failure to

comply with the recommendations stated

in this manual will damage the pump, and

void factory warranty.

iMPOrTAnT