Reassembly, Warranty, Permanent installations – SANDPIPER SMA3-A User Manual

Page 2

Warren Rupp, Inc. A Unit of IDEX Corporation P.O. Box 1568 Mansfield, Ohio 44901-1568 USA (419) 524-8388 Fax (419) 522-7867 • www.warrenrupp.com

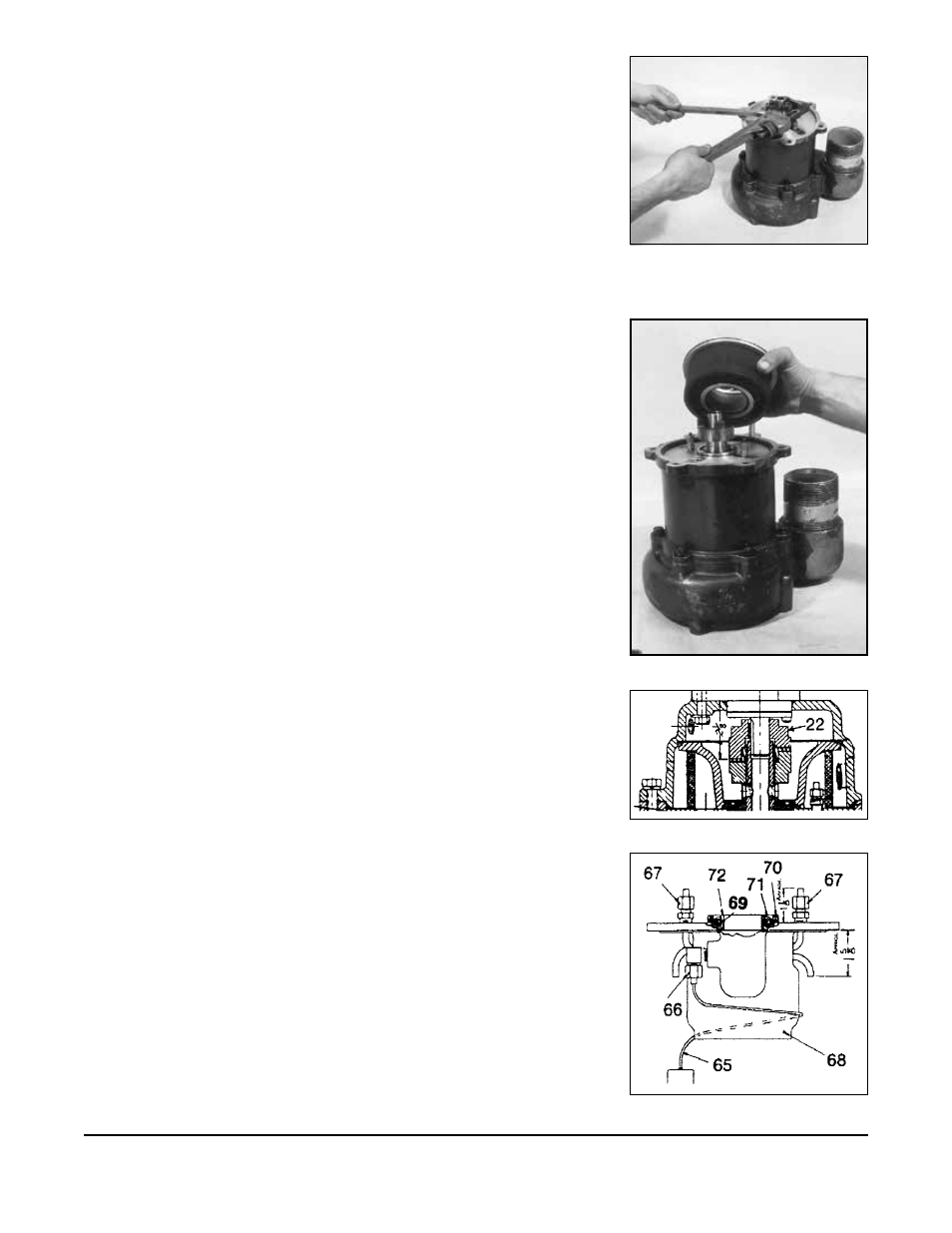

Remove strainer assembly secured with four cap nuts. Impeller is removed by

inserting block of wood, hammer handle, or similar object between impeller vane and

pump casing (see Figure 2) to prevent rotation and turn shaft counterclockwise from

air motor end with drift pin inserted through hole in shaft. Remove shaft assembly

from volute casing by removing snap ring above oil seal, bump shaft and bearing from

casing. Rotating portion of shaft seal can now be removed from shaft and stationary

seal seat can be removed from casing.

REASSEMBLY

When installing shaft seal on shaft use a lightweight oil and locate seal at extreme

end of shaft so that carbon face of seal will contact seal seat before bearing enters

housing bore during assembly. This eliminates the possibility of carbon washer falling

out of position in seal cage while bumping shaft and bearing assembly into correct

position. Push oil seal and retainer into bore above bearing and install snap ring. Install

governor weights, spool and spring if removed. Lay o-ring into casing bore and install

intermediate housing. Install o-ring and drop governor housing into position and push

down into place. Slide sleeve and spacer onto shaft with spacer and shaft holes in

alignment. Install coupling and tighten securely with drift pin and pipe wrench with

same procedure as removal. (See Figure 3.) Insert o-ring into filter housing bore and

press filter element and housing into position as shown. (See Figure 4.) Install o-ring

into intermediate bore and o-ring on to counter bore at upper end of filter housing.

Assembly is now ready to receive air motor and housing assembly. If coupling half

on air motor shaft is removed, make certain coupling is relocated to correct posi-

tion as indicated dimensionally in Figure 5. Line up coupling jaws for engagement

by using bolt holes of castings as a reference. Rubber spider should be installed in

lower coupling half. Lower air motor and housing into place slowly to feel for correct

coupling engagement. When coupling is properly engaged, assembly can be pushed

down by hand.

DO NOT FORCE ASSEMBLY TOGETHER WITH BOLTS. If air motor

assembly is lifted back up in attempting to engage blind coupling, make certain that

o-ring on top end of filter housing is still in position. If o-ring is out of position during

this blind assembly, air will by-pass the governor and over-speeding can occur. Fill

with recommended oil and run unit without pumping to check for possible oil leakage

at shaft seal or o-ring joints. Turn air supply on slowly to make certain that governor

is operating properly.

WARRANTY

This unit is guaranteed for a period of five years against defective material and

workmanship.

PERMANENT INSTALLATIONS

NOTE: As mentioned, the SMA3-A pump does require that oil be in the reservoir

for bearing and motor lubrication. For permanent installations remove item 66, then

plug the hole with a

1

/

8

" pipe plug, part number 618-002-330. Fill the reservoir and

make sure that an in-line oiler (type oil as recommended) is used in the air supply to

the pump. Set lubricator at a usage rate of 1 pint (473 cc) every 50 hours. The motor

will then be lubricated by the in-line oiler and the bearing by the oil in the reservoir.

Figure 3

Figure 4

Figure 5

Figure 6

sma3dl1sm-REV0714

Model SMA3-A Page 2