Explanation of pump nomenclature, hdb2, Materials, Ii 2gd t5 – SANDPIPER HDB2 User Manual

Page 4: Your serial, Model, Your model

hdb2smdl3sm-rev0614

Model HDB2 Page 2

Materials

Operating Temperatures

For specific applications, always consult “Chemical Resistance Chart" Technical Bulletin

Nitrile General purpose, oil-resistant. Shows good solvent, oil, water and hydraulic fluid resistance. Should

not be used with highly polar solvents

like acetone and MEK, ozone, chlorinated hydrocarbons and nitro hydrocarbons.

EPDM Shows very good water and chemical resistance. Has poor resistance to oil and solvents, but is fair in

ketones and alcohols.

NEOPRENE All purpose. Resistant to vegetable oils. Generally not affected by moderate chemicals, fats,

greases and many oils and solvents. Generally

attacked by strong oxidizing acids, ketones, esters, nitro hydrocarbons and chlorinated aromatic hydrocar-

bons.

HYTREL

®

Good on acids, bases, amines and glycols at room temperature.

PTFE Chemically inert, virtually impervious. Very few chemicals are known to react chemically with

PTFE: molten alkali metals, turbulent liquid or gaseous fluorine and a few fluoro-chemicals such as

chlorine trifluoride or oxygen difluoride which readily liberate free fluorine at elevated temperatures.

FKM (Fluorocarbon) shows good resistance to a wide range of oils and solvents; especially all aliphatic,

aromatic and halogenated hydrocarbons, acids, animal

and vegetable oils. Hot water or hot aqueous solutions (over 70°F) will attack FKM.

Santoprene

®

Injection molded thermoplastic elastomer with no fabric layer. Long mechanical flex life. Excel-

lent abrasion resistance.

Maximum

Minimum

‡

CF-8M Stainless Steel equal to or exceeding ASTM specification A743 for corrosion resistant iron chro-

mium, iron chromium nickel, and nickel based alloy castings for general applications. Commonly referred

to as 316 Stainless Steel in the pump industry.

190°F

-10°F

88°C

-23°C

280°F

-40°F

138°C

-40°C

200°F

-10°F

93°C

-23°C

220°F

-20°F

104°C

-29°C

220°F

-35°F

104°C

-37°C

350°F

-40°F

177°C

-40°C

275°F

-40°F

135°C

-40°C

Maximum and Minimum Temperatures are the limits for which

these materials can be operated. Temperatures coupled with

pressure affect the longevity of diaphragm pump components.

Maximum life should not be expected at the extreme limits of

the temperature ranges.

ALLOY C CW-12MW equal to or exceeding ASTM A494 specification for nickel and nickel alloy castings.

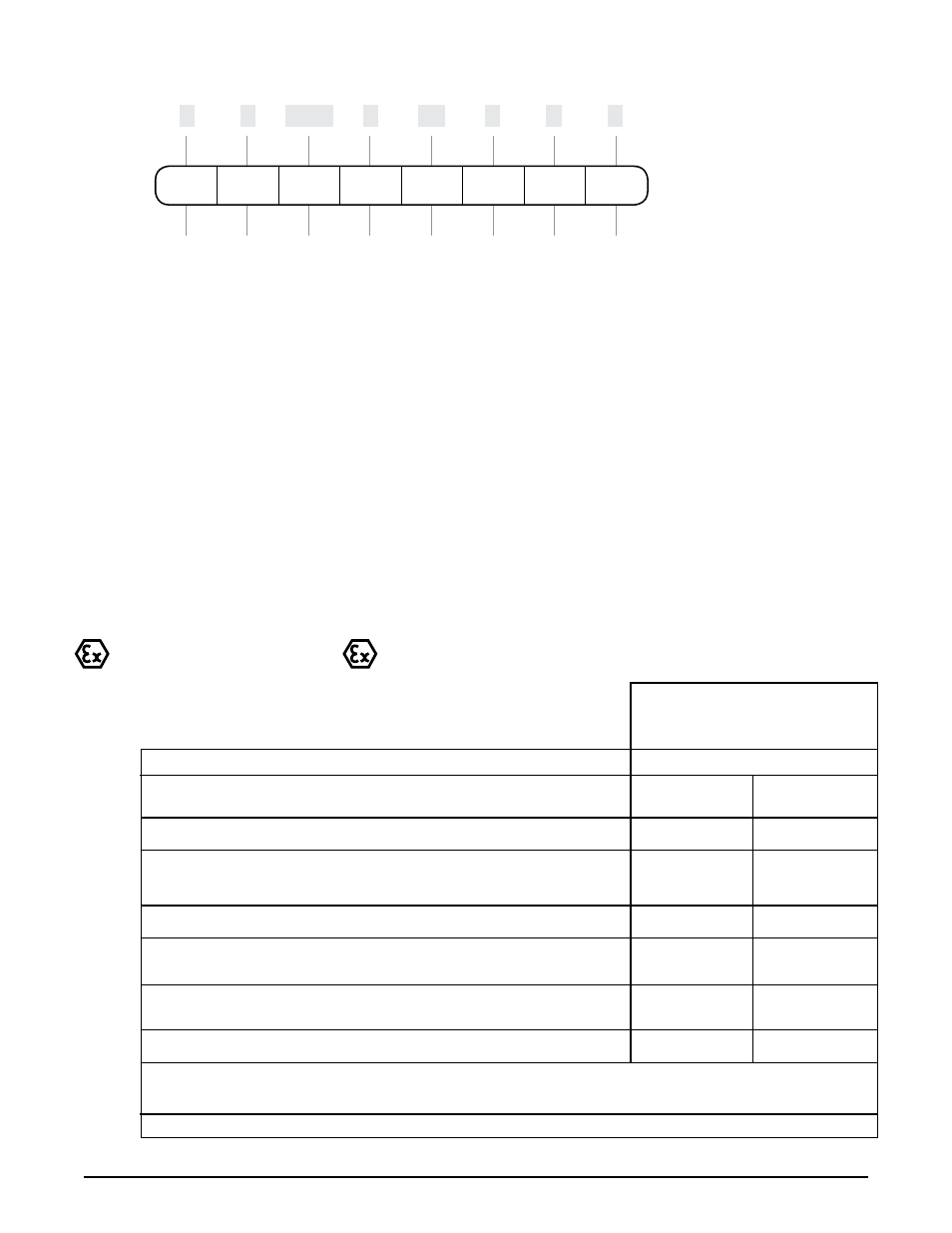

Explanation of Pump Nomenclature, HDB2

II 2GD T5

II 1 G c T5

II 3/1 G c T5

II 1 D c T100oC

I M1 c

I M2 c

Models equipped with

Cast Iron, Stainless

Steel, or Alloy C wetted

parts, and Cast Iron mid-

section parts. See page

19 for ATEX Explanation

of EC-Type Certificate.

II 2 G c T5

II 3/2 G c T5

II 2 D c T100oC

II 2GD T5

All models, including

pumps equipped with

Aluminum wetted and

midsection parts.

See page 19 for ATEX

Explanation of Type

Examination Certificate.

Diaphragm Check Valve Materials

B Nitrile

C FKM with PTFE

F FDA Accepted White Nitrile

GN Neoprene Backup with PTFE Overlay

and PTFE Check Balls

GR Hytrel Backup w/

PTFE Overlay/PTFE Balls

GZ PTFE/Nitrile Bonded

One-Piece/PTFE Balls

H EPDM with PTFE

N Neoprene

R Hytrel

S Santoprene

U Santoprene with PTFE

V FKM

Design Level

3

Construction

A Aluminum Wetted, Aluminum Air

SI Stainless Steel Wetted, Cast Iron Air

SS Stainless Steel Wetted, Aluminum Air

HC Alloy-C Wetted, Aluminum Air

HI Alloy-C Wetted, Cast Iron Air

Options

P1 Intrinsically Safe ATEX Compliant

Pulse Output

Pump Series

S SANDPIPER

®

Pump Design

B Soilid Ball

Pump Size

2 2"

Discharge Porting Position

D Bottom

S Side

ET Dual Top

ES Dual Side

Your Serial #:

(fill in from pump nameplate)

_____________________________________

__ __

_____

__ ___ __ __ __

Pump Pump Pump Options Discharge Diaphragm/ Design Construction

Series

Design

Size

Porting

Valve Level

XX X

XXXX,

X XX X XX X

Model #:

(fill in from pump

nameplate)

Your Model #: