Troubleshooting – RIKON Power Tools 80-805 User Manual

Page 17

TROUBLESHOOTING

TO PREVENT INJURY TO YOURSELF or damage to the Bench Grinder, turn the switch to the

“OFF” position and unplug the power cord from the electrical receptacle before making any

adjustments.

Page 16

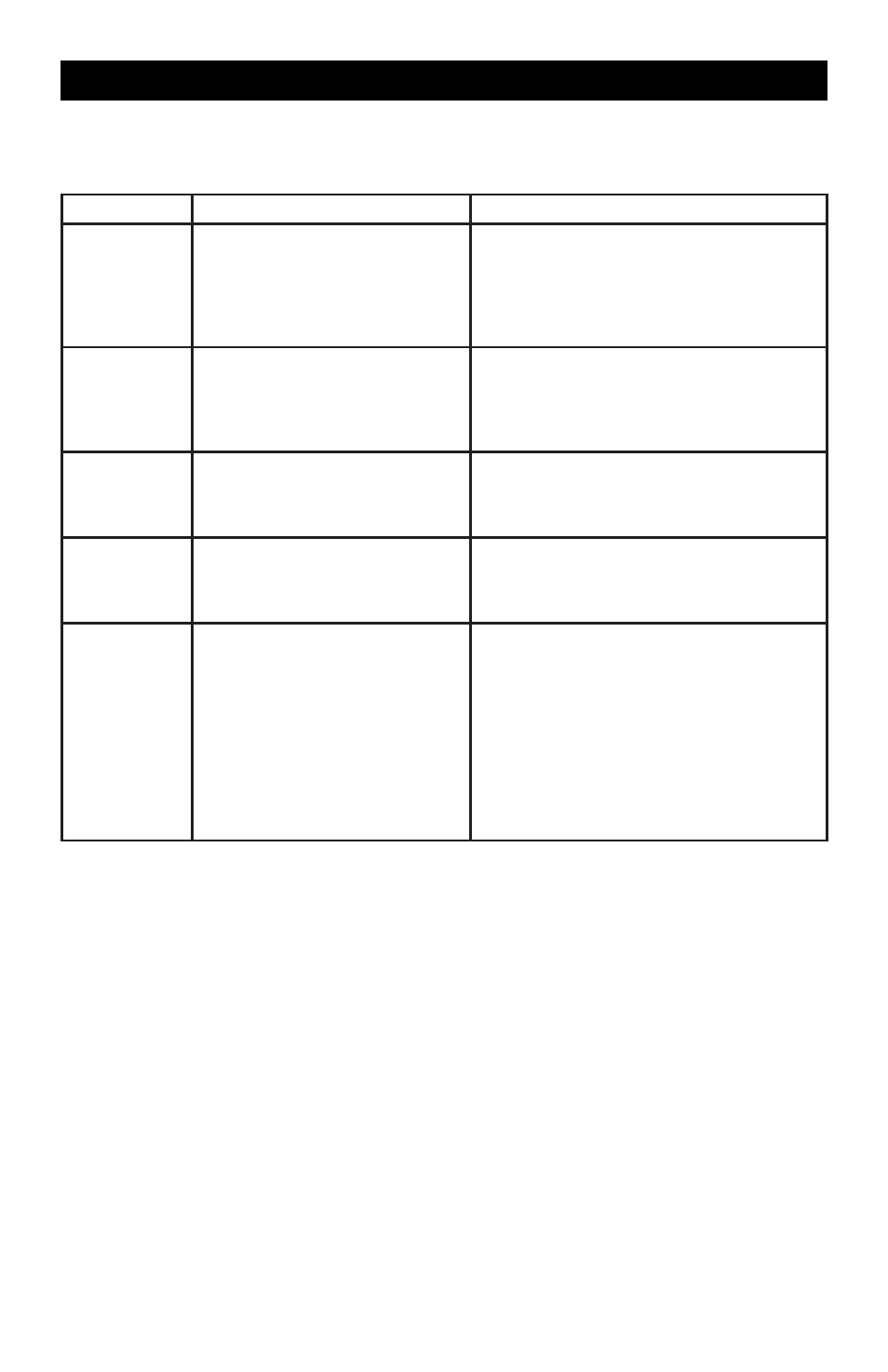

PROBLEM

LIKELY CAUSE(S)

SOLUTION(S)

Motor does

not run

1. Machine not plugged in

2. Power switch in “OFF” position

3. Power switch or cord is faulty

4. Fuse or circuit breaker are open

5. Material wedged between wheel

and tool rest or guard

1. Plug power cord into electrical receptacle

2. Lift switch to “ON” postion

3. Replace switch or power cord

4. Overloaded electrical circuit

5. Turn grinder off, unplug power cord and

remove material

Motor does

not have full

power

1. Incorrect line voltage

2. Motor capacitor has failed

1. Have a qualified electrican check circuit for

proper voltage

2. Replace motor capacitor

Motor runs hot

1. Motor is overloaded

2. Poor air circulation around motor

3. Overuse in high ambient

temperature room

1. Reduce pressure on workpiece

2. Remove any blockage around motor

3. Reduce runtime to 20 minutes or less

Motor stalls or

runs slow

1. Motor is overloaded

2. Incorrect line voltage

3. Motor capacitor has failed

1. Reduce pressure on workpiece

2. Have a qualified electrican check circuit for

proper voltage

3. Replace motor capacitor

Fuses blow or

circuit breaker

trips

1. Motor is overloaded

2. Overloaded electrical circuit

3. Undersized fuse or circuit breaker

4. Defective cord, plug or switch

creating a short circuit

5. Undersized or excessive length of

extention cord, see page 8

6. Material wedged between wheel

and tool rest or guard

1. Reduce pressure on workpiece

2. Reduce the amount of items on circuit

3. Replace with correct fuse or circuit breaker

4. Replace with new parts

5. Use correct size and length of extension cord

6. Turn grinder off, unplug power cord and

remove material

CORRECTING EXCESSIVE WHEEL WOBBLE

The performance of your bench grinder can be improved with just a little time performing a few

simple tune-up steps. Make sure the grinder is always unplugged during any adjustment or wheel

changes.

The stamped steel flange washers may not run perfectly true and can be adjusted by making a

reference mark on each flange washer and the wheel to record their original location. Next, loosen

the shaft nut and slightly rotate one flange washer clockwise and the other counterclockwise.

These movements should only be about one-half an inch at a time; then snug up the shaft nut by

hand and spin the wheel by hand. Observe any change. This rotation should minimize any

oscillation caused by flange washers. Now re-tighten the shaft nuts and dress the wheel. The

center bushings supplied by aftermarket grinding wheel manufacturers are designed to roughly

center the wheel on the shaft. The flange washers hold the wheel; dressing with a wheel dresser

will make the wheel run true.

If adjusting the flange washers does not make the wheel run without side-to-side oscillation, then

remove the wheel and flange washers and check the shoulder on the motor shaft at the point

where the flange washer seats against it. A slight burr on the edge of the shoulder can stop the

flange washer from seating properly. This can be removed by using a file to smooth the edge of

the shoulder. Look for any roughness on the surfaces of the flange washers and smooth these

spots on sandpaper placed on a flat surface. Then replace the wheel, re-adjust the flange

washers, and dress the wheel.