Adjustments, Fig. 27, Fig. 26 – RIKON Power Tools 23-400H User Manual

Page 16

16

ADJUSTMENTS

FIG. 27

10. When all belts have been checked and any mainten-

ace has been done, replace and secure the side panel

and speed control knob back to their positions with the

screws that were previously removed (In steps 2 & 3).

REPLACING THE DRIVE BELTS

1. To replace the

Cutterhead Drive Belt (#145, FIG.

26, A), follow the same steps, #2-6 above (page 15) to

remove the side panel and access the belts and pulleys.

Loosen the tension until both the Cutterhead Drive Belt

and the Feed Roller Belt (#152, B) can be easily removed

from both their pulleys.

The small Panel (#150, c) that surrounds the speed con-

trol arbor must be removed to slide the two used belts off

of the motor arbor. Once removed, reverse the steps to

install and re-tension the new belts on their pulleys.

2. To replace the

Feed Roller Belt (#152, B), the small

Panel (C) must first be removed. With the motor loose

and lifted, there should be enough slack to install a new

Feed Roller Belt. If not, the tensioning Spring (#184, D)

can also be un-hooked to allow the Cam Wheel Bracket

(#244) to swing loose. Re-fastened the spring once the

belt has been installed. Then reverse the steps to install

the drive belt and re-tension it on the pulleys.

3. When all work on the belts has been done, replace the

small panel, cabinet side panel, and the speed control

knob and secure them in position with the same screws

that were previously removed.

Drive Belt Adjustment continued from page

15

THE PLANER MUST NOT BE

PLUGGED IN AND THE POWER SWITCH MUST BE

IN THE OFF POSITION UNTIL ADJUSTMENTS ARE

COMPLETE.

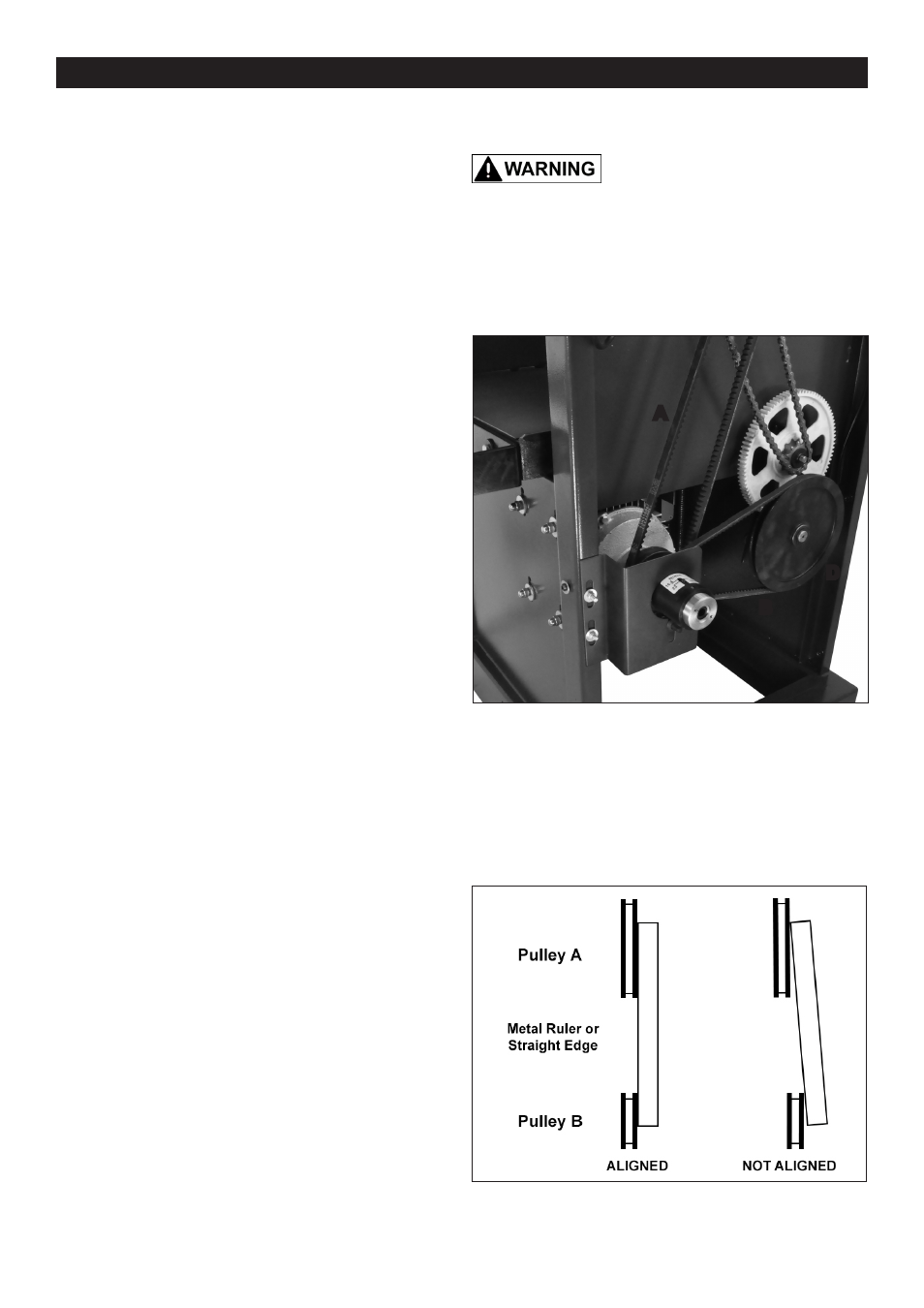

ALIGNING THE PULLEYS

The pulley positions for the belts are pre-set at the

factory for proper alignment to each other. If they are not

set correctly, excess wear to the belts and power transfer

may be reduced. While the side panel is open, the

pulleys should be checked to make sure that no move-

ment has occured during use.

1. With a metal straight edge, or perfectly flat board,

place the straight edge against the faces of the two

pulleys that are connected by the same belt. FIG. 27.

2. If the straight edge does not lie flat on both of the

pulley faces, one or both of the pulleys must be moved to

correct this miss-alignment.

3. Loosen the pulleys' set screws and shift the pulleys

along their shafts until they are properly aligned.

4. Tighten the pulley set screws and them re-check the

belt tension as described on page 15.

FIG. 26

A

B

C

D

MOTOR

MOUNT