RIKON Power Tools 10-308 User Manual

Page 13

13

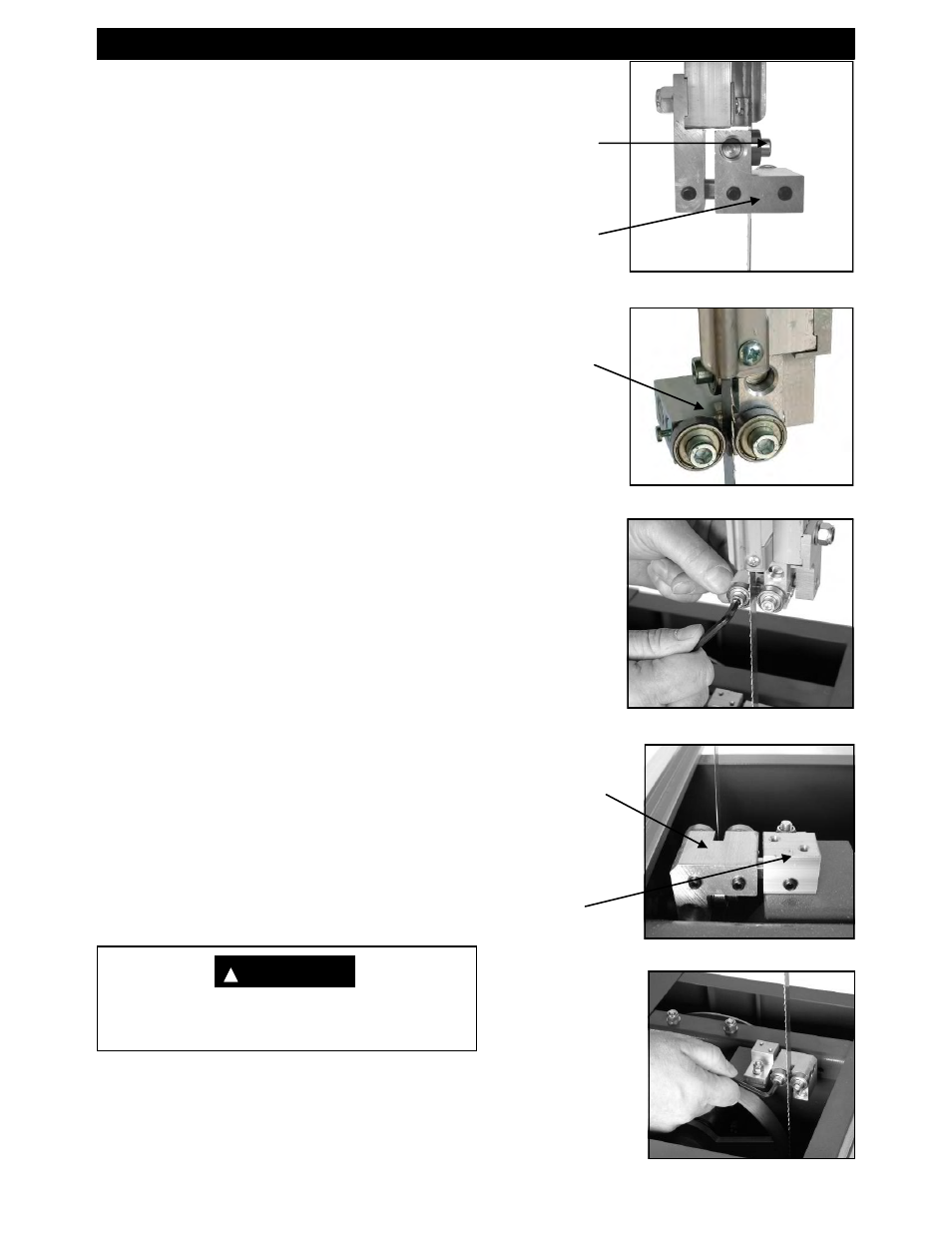

Thrust Bearing

Cap Screw

Bearing Block

A

B

C

Block

G

E

F

Block

Bearing Block

Loosening Side

Bearing Cap

Screws

Loosening

Side Bearing

Cap Screws

Side Blade

Bearings

D

Adjustments

Blade Guide Adjustment

Proper guide adjust is important to the proper opera-

tion of the bandsaw and will extend the life of the

bandsaw blade.

In general the guide bearings should be close

enough to guide the bandsaw blade to control deflec-

tion during the cut but not tight against the blade.

Positioning the bearings too close against the blade

causes too much friction and can work

-harden the

blade causing premature blade failure.

Upper Blade Guide

The set screws on the back of the upper guide A, B,

and C are used to position the guide assembly along

a shaft.

A moves the entire bearing block and B & C are used

to center the bearing block to the blade.

First make sure the shaft is flush with the block.

Loosen A make flush and lock.

To center the thrust bear behind the back of the

blade loosen set screws B & C center bearing

block and tighten.

To adjust the thrust bearing loosen the cap screw

and move the bearing so it is approximately .015”

away from the back of the blade and tighten.

(Folding a piece of paper 4 times is close).

Adjust the side bearings by loosening the corre-

sponding cap screws and by moving the adjust-

ment pins (D), to position the bearings

within .004” of the blade and tighten. (Single pa-

per thickness is fairly close).

Lower Blade Guide

The lower blade guide adjustments work in similar

fashion as the upper guide. The block holds the bear-

ing block in place along a shaft.

The bear block assembly can be adjusted along

the shaft by loosening the set screw G position-

ing and then re-tightening.

Loosen the set screws E & F. Center the bearing

block to the blade and tighten.

Adjust the side blade bearings by loosening the

corresponding cap screws and slide the bearings

to within .004” of the blade and tighten. (Single

paper thickness is fairly close).

Make sure the bandsaw is disconnected from the

power source before making any adjustments.

WARNING

!