Site preparation, Frame assembly, Assembly instructions – Rhino Shelter EXT ROUND-12WX24LX8H User Manual

Page 3

Assembly Instructions

Extended Round Style 12 x 24 x 8

V2.2

Please Do NOT Return Assembly to Dealer or Store. For All questions or Shortages please call MDM Products directly

Customer Service 800-447-7079 or 203-877-7070

3

SITE PREPARATION

Select a level or as close to level as practical location for

your Rhino Shelter unit. The unit should be placed on a

base of materials suitable for the storage load to be

protected. The unit should not be located under trees,

which will shed hard fruit such as apples, walnuts, or

heavy pine cones. The cover of your unit will protect

against normally leaves and light debris, however large

branches or other falling items may cause puncture or

tears in the cover material.

Take notice of drainage around your intended location.

Water draining from the surrounding terrain should be

planned so that it does not run into the unit. As well, rain

or melting snow that comes off the unit should be

drained away rather than accumulate and pool around

the unit.

Check to be certain that adequate clearance is allowed

for entry and exit from ends of unit. As unit has doors on

both ends, ideally vehicle or equipment can be inserted

or removed from either end.

FRAME ASSEMBLY

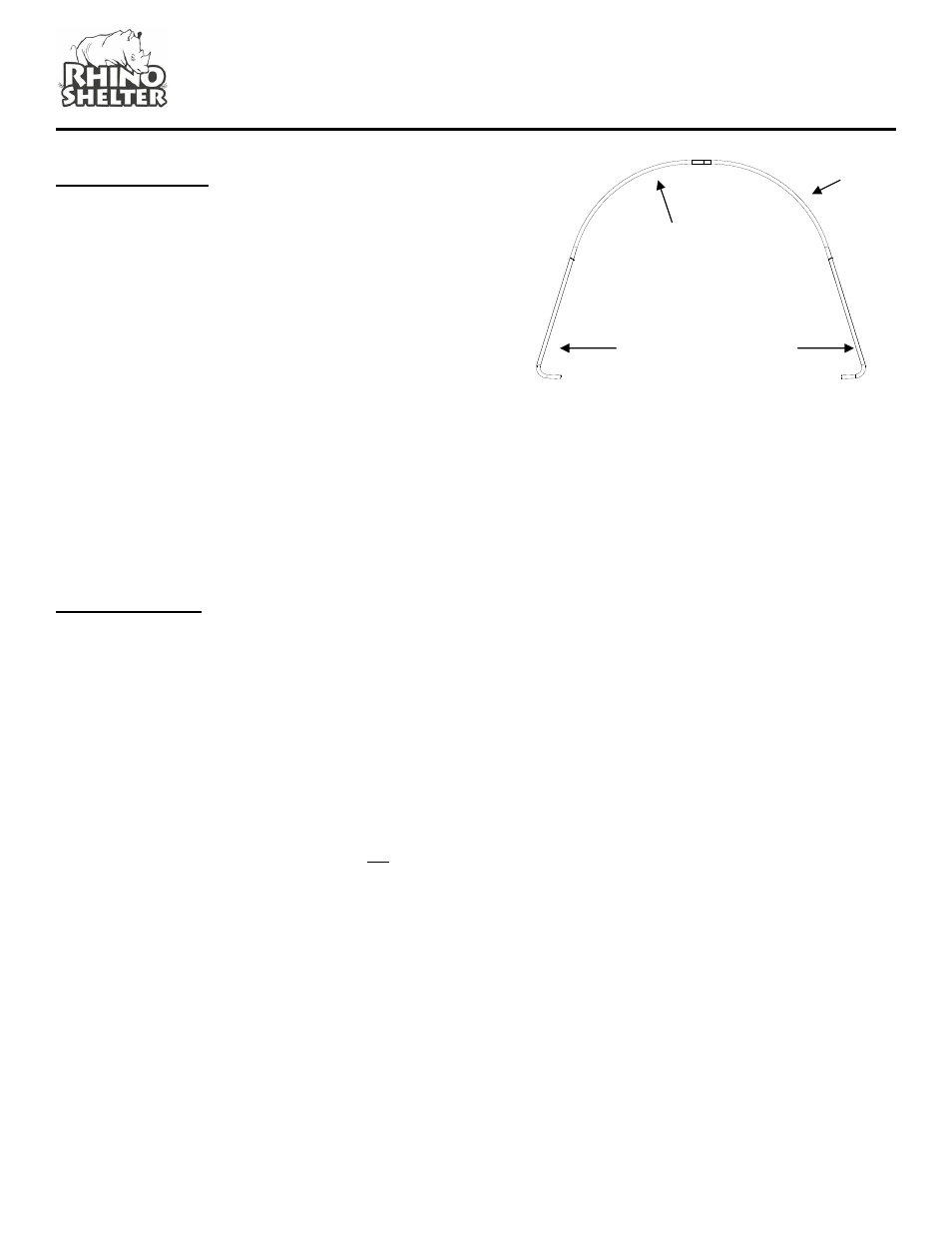

Step1. Assemble the two End Arch Assemblies. Each

consists of (1) Right Side Crest Tube RC-3020, (1) Left

Side Crest Tube LC-3021 and (2) End Upright w/Foot

EUL-4021 for each one. Assemble as shown below.

The swedged ends slip into the plain end pipe of the

adjoining frame member. Use (4) CBN-3005-3 carriage

bolts with nuts and curved washers through pre-drilled

holes in frame members.

Be certain to insert carriage bolts from the outer edge

into the interior of the unit, with the washers and nuts on

the inside of the arches. This will avoid tearing the fabric

on doors and main cover when installed. Do not tighten

the nuts completely until the frame is completed and set

in place.

Step 2. Attach the (2) Corner Wind Braces CW-1800

(flattened ends) to the End Upright w/Foot EUL-4021 to

the first of the End Arch assemblies. Use a CBN-3005-2

Carriage Bolt with Washer and Nut to secure the braces

loosely to the Upright, into the hole just below the side

cross rail. Do not tighten completely.

Step 3. Assemble the Five Interior Arch Assemblies

using (1) Right Crest Tube RC-3020, (1) Left Crest Tube

LC-3021, and (2) Center Straight Upright CSU-4020 for

each. Use CBN-3000-3 carriage bolts with washers and

nuts in the pre-drilled holes, aligned to form each arch.

Place aside for the moment.

Step 4. Support an End Arch with Wind Braces CW-

1800 temporarily in the vertical position. Connect (4)

ECR-2031 Plain End Cross Rails to the inside of the End

Arch onto the (4) CBN-3005-3 carriage bolts that

assembled the interior arch members. The Cross Rails

should be put into the bottom and side hole of each arch

upright. These will begin the Base Cross Rails and Side

Cross Rails on each side of the frame assembly. Again,

don’t tighten the hardware until the next arch and cross

rails are assembled.

Step 5. Stand an Interior Arch Assembly up vertically

approximately 48” from the End Arch Assembly with

cross rails. Align the cross rails from the End Arch with

the carriage bolt holes in the Interior Arch. Remove the

(4) nuts and washers on the carriage bolts, and connect

the cross rails between the End Arch and the first Interior

Arch. Connect the (2) Wind Braces #CW-2005

diagonally across the end and interior arch as shown in

the frame illustration.

RC-3020 Right

Crest Tube

LC-3021 Left

Side Crest Tube

EUL-4021 End Upright

With Foot