Operation, Constant current (cc-stick) welding, B-5 tig welding – Lincoln Electric IM976 VANTAGE 300 User Manual

Page 23: Typical vantage® 300 fuel consumption

B-5

OPERATION

B-5

TIG WELDING

The TOUCH START TIG setting of the MODE switch is

for DC TIG (Tungsten Inert Gas) welding. To initiate a

weld, the OUTPUT CONTROL dial is first set to the

desired current and the tungsten is touched to the work.

During the time the tungsten is touching the work there is

very little voltage or current and, in general, no tungsten

contamination. Then, the tungsten is gently lifted off the

work in a rocking motion, which establishes the arc.

When in the TOUCH START TIG mode and when a

Amptrol is connected to the 6-Pin connector the OUT-

PUT CONTROL dial is used to set the maximum cur-

rent range of the current control of the Amptrol.

The ARC CONTROL is not active in the TIG mode. To

STOP a weld, simply pull the TIG torch away from the

work. When the arc voltage reaches approximately 30

Volts the arc will go out and the machine will reset the

current to the Touch Start level.

To reinitiate the arc, retouch the tungsten to the work

and lift. Alternatively, the weld can be stopped by

releasing the Amptrol or arc start switch.

VANTAGE® 300

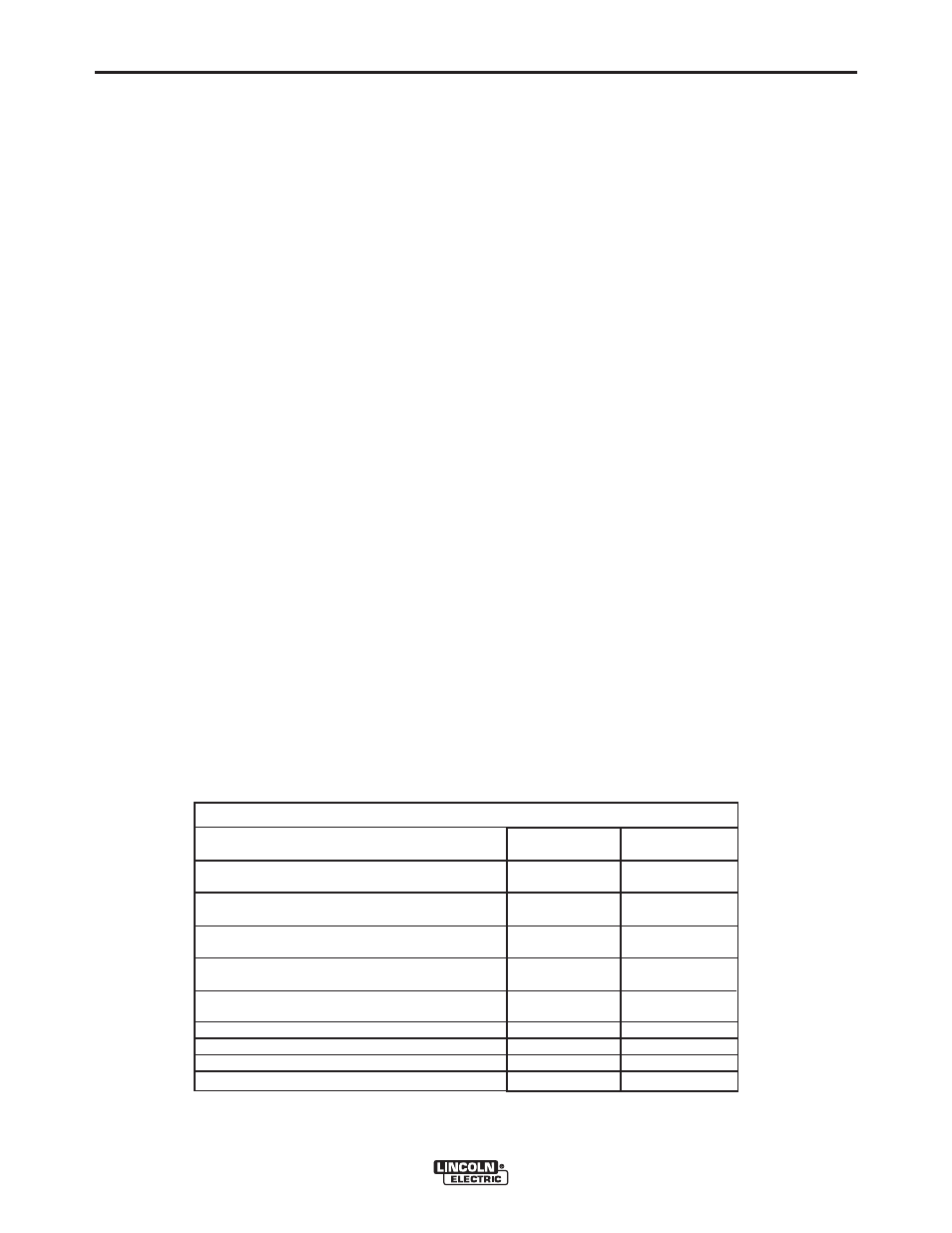

TYPICAL VANTAGE® 300 FUEL CONSUMPTION

TABLE B.1

Deutz D2008 L4

Gal./Hr (Liters/Hr)

---------

.34 (1.30)

---------

.46 (1.75)

-----------

.64 (2.41)

-----------

.86 (3.24)

-------------

1.22 (4.62)

1.10 (4.15)

.89 (3.36)

.73 (2.75)

.58 (2.18)

Running Time for

15 gallons - (Hours)

--------

43.81

--------

32.46

--------

23.54

--------

17.52

--------

12.28

13.67

16.88

20.65

26.07

1400 R.P.M.

1800 R.P.M.

DC Weld Output 150 Amps @ 20 Volts

DC Weld Output 250 Amps @ 24 Volts

DC Weld Output 300 Amps @ 32 Volts

10,000 Watts

7,500 Watts

5,000 Watts

2,500 Watts

NOTE: This data is for reference only. Fuel consumption is approximate and can be influenced

by many factors, including engine maintenance, environmental conditions and fuel quality.

CONSTANT CURRENT (CC-STICK) WELDING

The CC-STICK position of the MODE switch is designed

for horizontal and vertical-up welding with all types of elec-

trodes, especially low hydrogen. The OUTPUT CONTROL

dial adjusts the full output range for stick welding.

The ARC CONTROL dial sets the short circuit current

(arc-force) during stick welding to adjust for a soft or crisp

arc. Increasing the number from -10(soft) to +10(crisp)

increases the short circuit current and prevents sticking of

the electrode to the plate while welding. This can also

increase spatter. It is recommended that the ARC CON-

TROL be set to the minimum number without electrode

sticking. Start with the dial set at 0.

DOWNHILL PIPE Welding

This slope controlled setting is intended for "out-of-posi-

tion" and "down hill" pipe welding where the operator

would like to control the current level by changing the arc

length.

The OUTPUT CONTROL dial adjusts the full output range

for pipe welding.

The ARC CONTROL dial sets the short circuit current

(arc-force) during stick welding to adjust for a soft or more

forceful digging arc (crisp). Increasing the number from -

10(soft) to +10(crisp) increases the short circuit current

which results in a more forceful digging arc.Typically a

forceful digging arc is preferred for root and hot passes. A

softer arc is preferred for fill and cap passes where weld

puddle control and deposition (“stacking” of iron) are key

to fast travel speeds. This can also increase spatter.

It is recommended that the ARC CONTROL be set to the

minimum number without electrode sticking. Start with the

dial set at 0.

Low Idle - No Load

High Idle - No Load