Troubleshooting, Caution – Lincoln Electric IM865 TANDEM MIG 800 AMPERAGE WELDING TORCH S22693-121,-122,-123,-124,-133 User Manual

Page 20

D-2

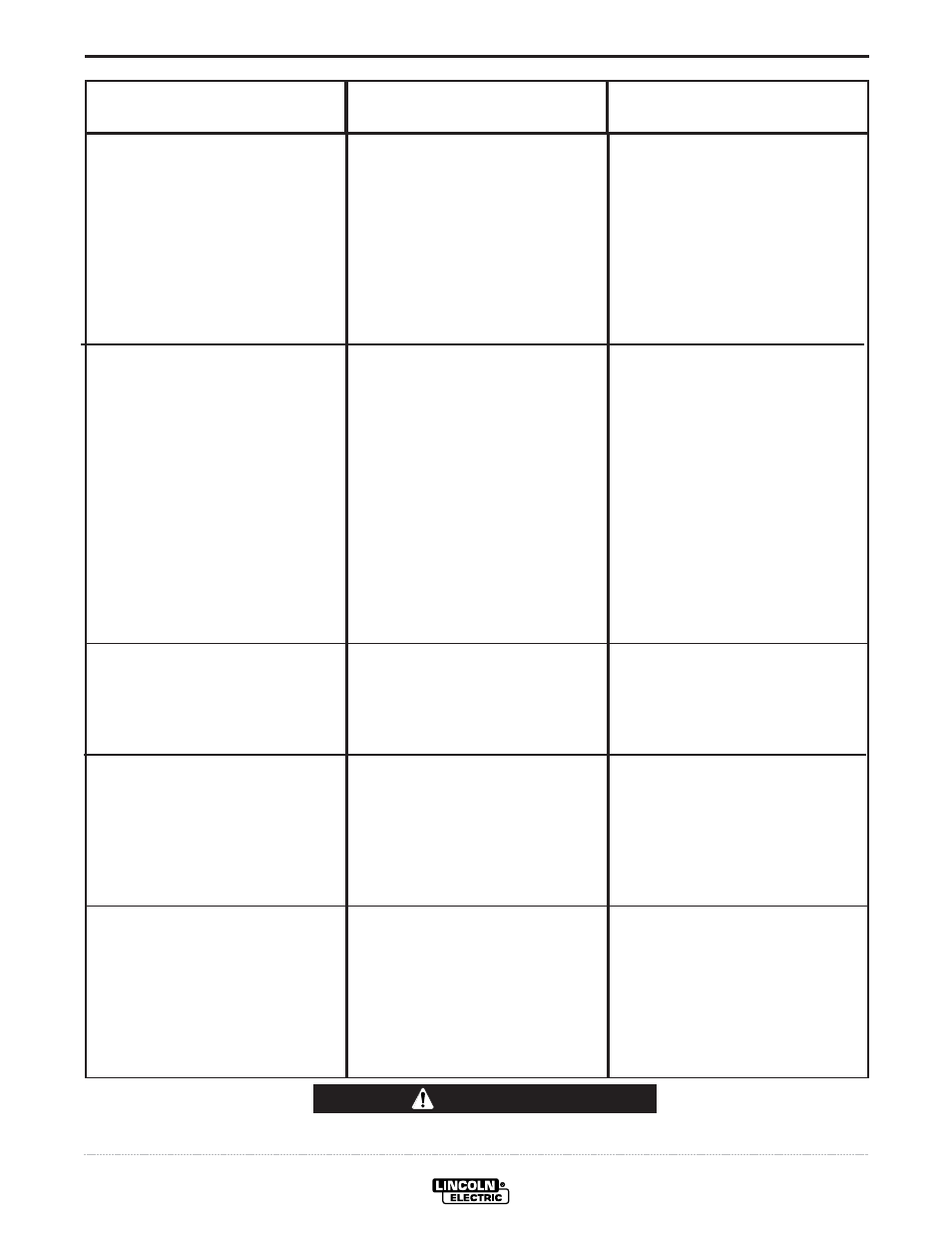

TROUBLESHOOTING

D-2

800 AMP TANDEM MIG TORCH

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility

for technical troubleshooting assistance before you proceed.

CAUTION

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

The drive rolls turn, but wire will

not feed or wire feeding is rough.

Porosity in the weld.

There is arcing in the nozzle.

The welding arc is inconsistent.

Inconsistent wire feeding.

1. Torch cable is kinked and /or twisted.

2. Wire jammed in torch or cable.

3. Incorrect or worn drive rolls and guide

tubes.

4. Partially flashed, melted or improper

contact tip size.

1. Welding surface is contaminated.

2. Insufficient gas coverage.

3. Excessive arc length.

4. Inoperative gas solenoid.

5. Contaminated shielding gas.

6. Excessive use of anti-spatter fluid.

1. Spatter build-up is bridging between

the nozzle and the contact tips, or

from contact tip to contact tip.

2. The torch is not insulated from part

tooling or fixture.

1. Worn or loose contact tip.

2. Loose connection in current path.

3. The wire conduit or liner is dirty or

worn.

1. Loose, worn or incorrect drive rolls.

2. Torch cable kinked or liner worn.

3. Wire pay-off dispenser malfunction-

ing.

1. Keep cable assembly as straight as

possible. Inspect cable and replace if

necessary.

2. Check for any obstructions in cable

assembly. Check liner, replace if nec-

essary.

3. Be sure the wire diameter being used

matches the drive rolls and guide

tubes size.

4. Replace contact tip.

1. Remove dirt, oil, moisture, mill scale

and miscellaneous contamination

from part.

2. Check for sufficient shielding gas flow

form source, or restriction in gas line.

Check for drafts that may force

shielding gas from welding arc.

3. Check weld procedures, arc length

should generally be less than 1/4"

and steady.

4. Check solenoid operation.

5. Check for leaks in gas hoses and gas

hose connections.

6. Check amount of anti-spatter being

applied and accumulation in nozzle.

1. Remove spatter build-up on regular

basis. Adjust weld procedure to

reduce spatter.

2. Make sure torch is properly insulated.

1. Inspect contact tip, tighten and

replace if necessary.

2. Check electrode and work cable con-

nections. Check torch connections at

wire feeder, diffuser and goosenecks.

3. Clean liner and conduit. Replace if

necessary.

1. Inspect drive rolls, tighten, clean or

replace as necessary.

2. Check cable for severe bends or

kinking. Check, and clean liner as

neccesary.

3. Check dispenser, make sure moving

parts are free from obstruction and

welding wire is properly routed.