Troubleshooting, Caution – Lincoln Electric IM557 Synergic 7 and 7H User Manual

Page 39

E-6

TROUBLESHOOTING

E-6

SYNERGIC 7 & 7H

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

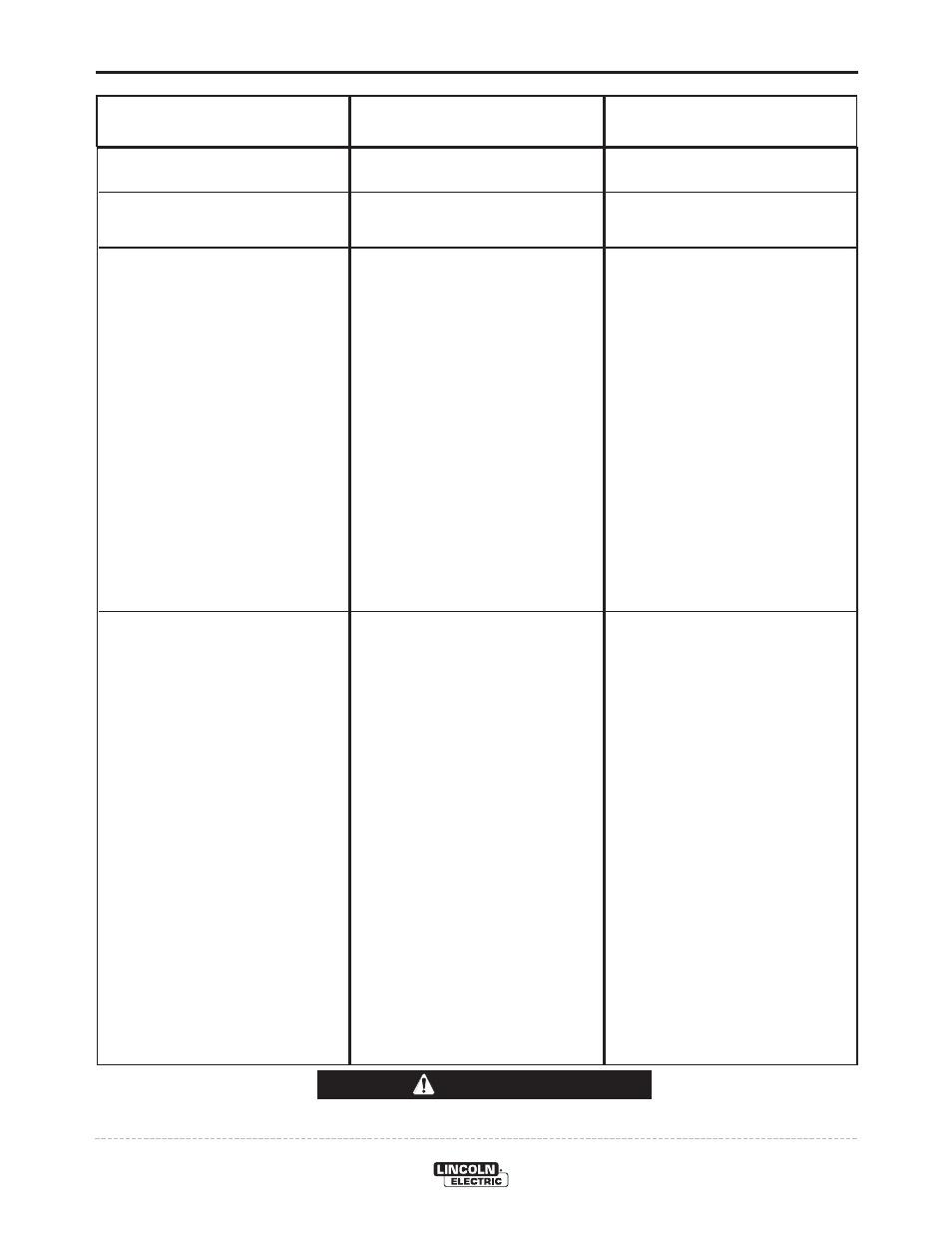

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

12. Arrow keys do not change Weld

speed or volts/trim.

13. WFS knob does not change

Run-in speed.

14. WFS and preset Volts/Trim para-

meters on wire feeder display do

not match those on power

source display.

15. Display does not change when

WFS and/or Volts/Trim knobs

are turned.

a. This is normal, as only the WFS and

volts/trim knobs will adjust these settings.

a. This is normal, as only the arrow

keys will adjust this setting.

a. Power source is defective.

b. Problem with serial communica-

tions in control cable.

c. Problem with wire feeder harness

or Control PCB.

a. A remote control kit is connected.

b. Broken harness wire(s) or harness

disconnected from Encoder

board(s) or Control board.

c. Defective Encoder boards and/or

Control board.

a. Refer to operation section of this manual

a. Refer to operation section of this manual.

a. If parameters on power source and wire

feeder display match when wire feeder is

connected to the other input receptacle (#1

or #2) of power source then power source

is defective.

b. Disconnect input cable from power source

and wire feeder. Check continuity between

socket G of 8-socket plug and pin G of 14

pin plug of the input cable. Check continu-

ity between socket H of 8-socket plug and

pin H of 14-pin plug of the input cable.

Replace cable if no continuity.

c. Remove molex plug P1 from J1 on Control

PCB. Check continuity from pin G of 8-pin

receptacle on wire feeder to pin 4 of plug

P1, and from pin H of 8-pin receptacle to

pin 3 of plug P1. If no continuity then repair

harness, otherwise replace Control PCB.

(See procedure for replacing PC boards.)

a. When a remote control kit is connected to

the Wire Feeder, the WFS and Volts/Trim

knobs of the Wire Feeder become inactive

and the WFS and Volts/Trim knobs of the

remote control kit must be used.

b. Check for continuity between correspond-

ing harness leads of molex plug P2 on

Control board and molex plugs P12 and

P13 on Encoder boards (refer to wiring dia-

gram). If any of these continuity tests fail,

repair or replace harness.

c. If b. is not the problem and neither the WFS

or Volts/Trim knobs are properly adjusting

then replace the Control board. If one of

the knobs is properly adjusting, plug the

harness, P12 or P13, from the working

board into the nonfunctional board. If the

previously nonfunctional board is now work-

ing then replace the Control board, other-

wise replace the nonfunctional Encoder

board. (See procedure for replacing PC

boards.)