Maintenance – Lincoln Electric IM949 SAE400 User Manual

Page 22

D-3

MAINTENANCE

D-3

GFCI RECEPTACLE TESTING AND RESET-

TING PROCEDURE

The GFCI receptacle should be properly tested at least

once every month or whenever it is tripped. To proper-

ly test and reset the GFCI receptacle:

• If the receptacle has tripped, first carefully remove

any load and check it for damage.

• If the equipment has been shut down, it must be

restarted.

• The equipment needs to be operating at high idle

speed and any necessary adjustments made on the

control panel so that the equipment is providing at

least 80 volts to the receptacle input terminals.

• The circuit breaker for this receptacle must not be

tripped. Reset if necessary.

• Push the "Reset" button located on the GFCI recep-

tacle. This will assure normal GFCI operation.

• Plug a night-light (with an "ON/OFF" switch) or other

product (such as a lamp) into the GFCI receptacle

and turn the product "ON".

• Push the "Test" button located on the GFCI recepta-

cle. The night-light or other product should go "OFF".

• Push the "Reset" button, again. The light or other

product should go "ON" again.

If the light or other product remains "ON" when the

"Test" button is pushed, the GFCI is not working prop-

erly or has been incorrectly installed (miswired). If your

GFCI is not working properly, contact a qualified, certi-

fied electrician who can assess the situation, rewire the

GFCI if necessary or replace the device.

SAE-400

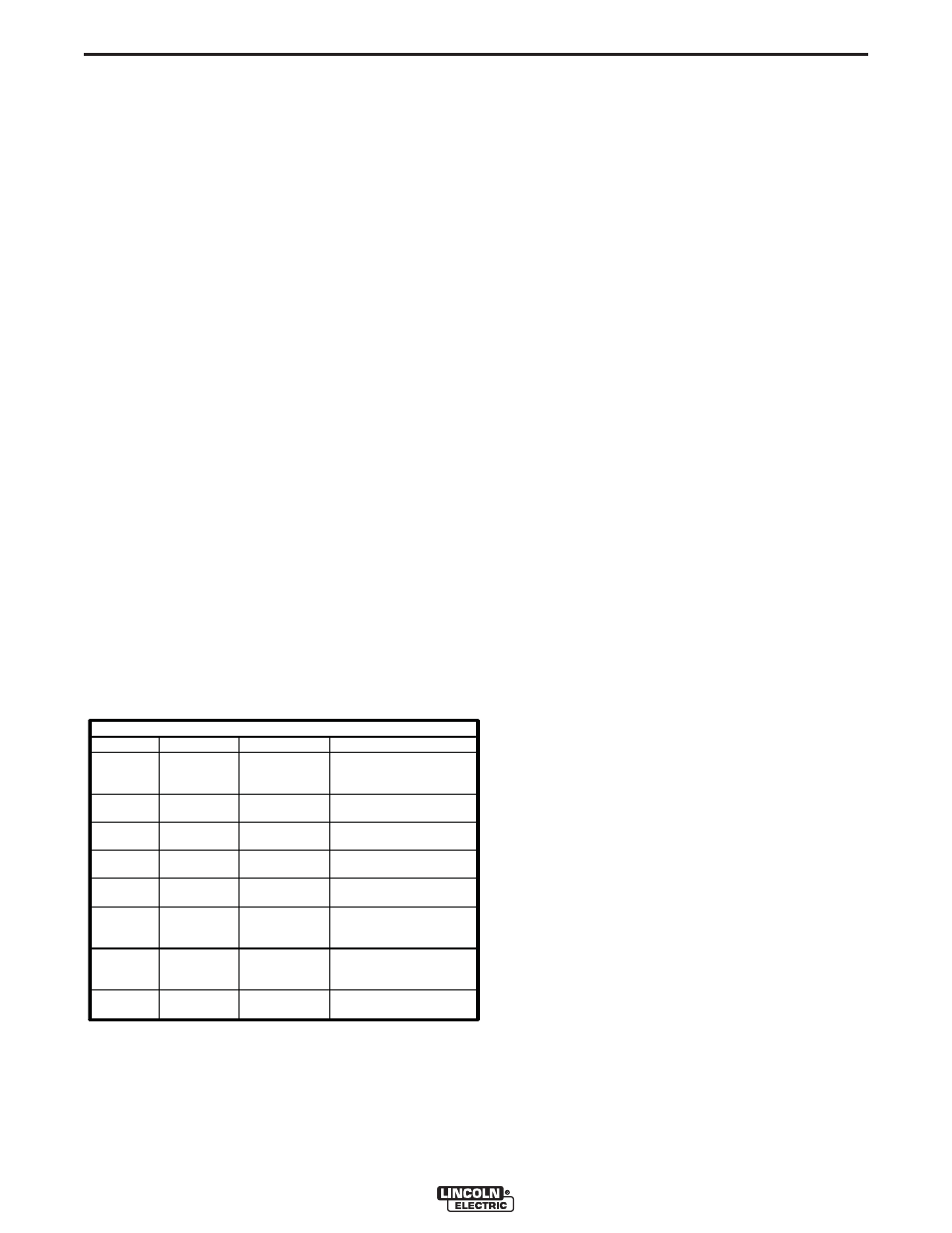

ENGINE AND COMPRESSOR MAINTENANCE

COMPONENTS

REPLACEMENT SERVICE ITEMS

ITEM

MAKE

PART NUMBER

SERVICE INTERVAL

AIR

CLEANER

ELEMENT

DONALDSON

P822768

CLEAN AS NEEDED.

REPLACE EVERY 200

HOURS

OIL FILTER

ELEMENT

DEUTZ

01182001

SEE DEUTZ MAINTANCE

DECAL

FUEL FILTER

ELEMENT

DEUTZ

01181917

SEE DEUTZ MAINTANCE

DECAL

FUEL PUMP

STRAINER

DEUTZ

X

SEE DEUTZ MAINTANCE

DECAL

FUEL

PRE-FILTER

LINCOLN

M21584

INSPECT EVERY 1000

HOURS

WATER

SEPARATOR

ELEMENT

LINCOLN

M21584-B

REPLACE EVERY 1000

HOURS

COOLING

BLOWER

BELT

DEUTZ

01182810

INSPECT EVERY 250

HOURS

BATTERY

X

BCI GROUP 24

INSPECT EVERY 500

HOURS

4. Slide the new element onto the grommet post on the

bottom of the filter header until the element no longer

easily moves up into the filter header. Now rotate the

element (may take almost 1 full turn) with a slight

upward pressure until the element begins to further

engage the header. With the proper orientation now

established apply additional pressure to seat the ele-

ment in the filter header. You should feel the element

“pop” into place when properly seated.

Note: The element will only go on one way. Never

use excessive force when mounting the element to

the header.

5. Slide the quick change ring up over the element and

rotate counter clockwise until an audible click or pop is

heard. If you do not hear the click you have not rotated

the ring far enough and the element is not in the locked

position. Another indication that the ring is in the locked

position is that one set (it doesnʼt matter which one) of

arrows located on the outside of the ring should be

located directly under the air vent valve.

6. Remove the see-through bowl from the old element

and install on the new element.

7. Open the fuel shutoff valve.

8. Open the air vent valve on the front of the filter header

until fuel emerges free of air bubbles and then close the

air vent valve.

Note: Consult your engine operation manual for

information on air bleeding the entire fuel system.