Operation, Process guidelines – Lincoln Electric IM810 PRO-MIG 175 User Manual

Page 18

B-5

B-5

OPERATION

Making A Weld

1. See “Process Guidelines” in this section for selec-

tion of welding wire and shielding gas and for

range of metal thicknesses that can be welded.

2. See the Application chart on the inside of the wire

feed compartment door for information on setting

the Pro-MIG 175 controls. Refer to Table B.1 for

aluminum and stainless wire.

3. Set the Voltage (“V”) and Wire Speed (“olo’”) con-

trols to the settings suggested for the welding wire

and base metal thickness being used, refer to

3.

Applications chart on the inside of the wire drive

compartment door.

4. Check that the polarity is correct for the welding

wire being used and that the gas supply, if

required, is turned on.

5. When using Innershield electrode, remove the gas

nozzle and install the gasless nozzle. This will

improve visibility of the arc and protect the gas dif-

fuser from weld spatter. Refer to the MAINTE-

NANCE section for details on nozzle replacement.

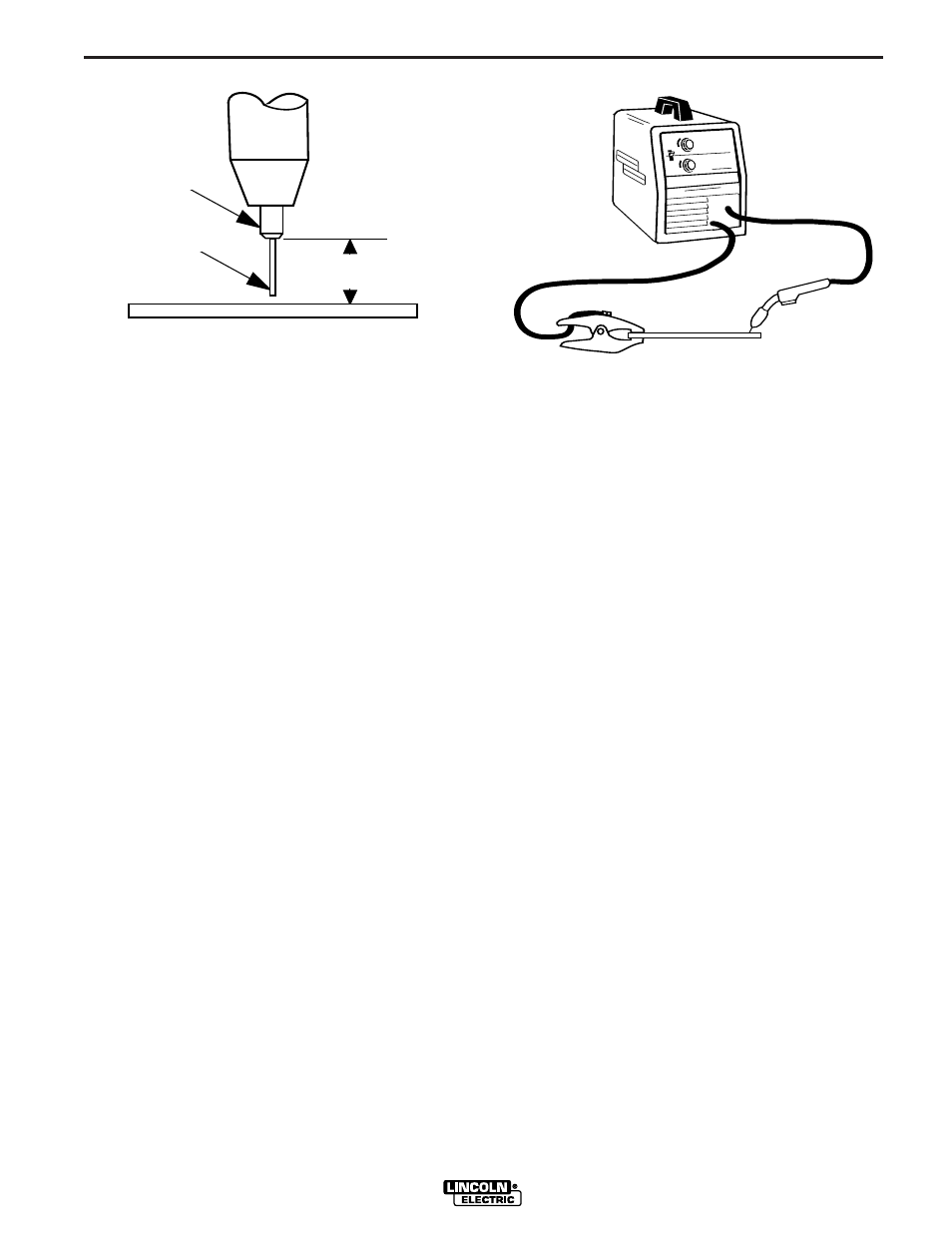

6. Refer to Figure B.7. Connect work clamp to metal

to be welded. Work clamp must make good elec-

trical contact to the workpiece. The workpiece

must also be grounded as stated in “Arc Welding

Safety Precautions” in the beginning of this manu-

al.

7. Position gun over joint. End of wire may be lightly

touching the work.

8. Lower welding helmet, close gun trigger, and

begin welding. Hold the gun so the contact tip to

work distance is about 3/8 inch (10 mm).

9. To stop welding, release the gun trigger and then

pull the gun away from the work after the arc goes

out.

FIGURE B.6

10. When no more welding is to be done, close valve

on gas cylinder (if used), momentarily operate gun

trigger to release gas pressure, and turn off the

Pro-MIG 175.

Cleaning Tip And Nozzle

Clean the contact tip and nozzle to avoid arc bridging

between the nozzle and contact tip which can result in

a shorted nozzle, poor welds and an overheated gun.

Hint: Anti-stick spray or gel, available from a welding

supply distributor, may reduce buildup and aid in spat-

ter removal.

PROCESS GUIDELINES

The Pro-MIG 175 can be used for welding mild steel

using the GMAW, single pass, process which requires

a supply of shielding gas or it can be used for the self-

shielded, Innershield

®

process (FCAW).

The recommended gases and electrodes for GMAW

are welding grade CO

2

gas or an argon-CO

2

blended

gas (75 to 80% argon and 25 to 20% CO

2

) and .025"

(0.6 mm) diameter Lincoln Super Arc L-56 mild-steel

welding wire. The blended gas is recommended for

welding on heavier steel, 14 gauge (2.0 mm), for

example.

The recommended electrode for the self-shielded

process is Lincoln Innershield

®

NR-211-MP. This elec-

trode is available as .035" (0.9 mm) and .045" (1.2

mm) NR-211-MP for all position welding of 18 gauge

(1.2 mm) through 5/16" (8.0 mm) steel. Thickness of

1/4" (6.4 mm) and 5/16" (7.9 mm) require multiple

passes. both wire sizes can also be used for the weld-

ing of galvanized coated sheet metal.

Contact Tip

Wire Electrode

FIGURE B.7

WORKPIECE

GUN CABLE

ARC

WORK CLAMP

Pro-MIG 175

3/8"– 1/2"(10-13mm) Contact

Tip to Work Distance(CTWD)