Operation, Changing machine over to feed other wire sizes, Welding with gmaw (mig) – Lincoln Electric IM787 PRO-MIG 135 User Manual

Page 19: Welding with fcaw (innershield), Overload protection

B-6

OPERATION

B-6

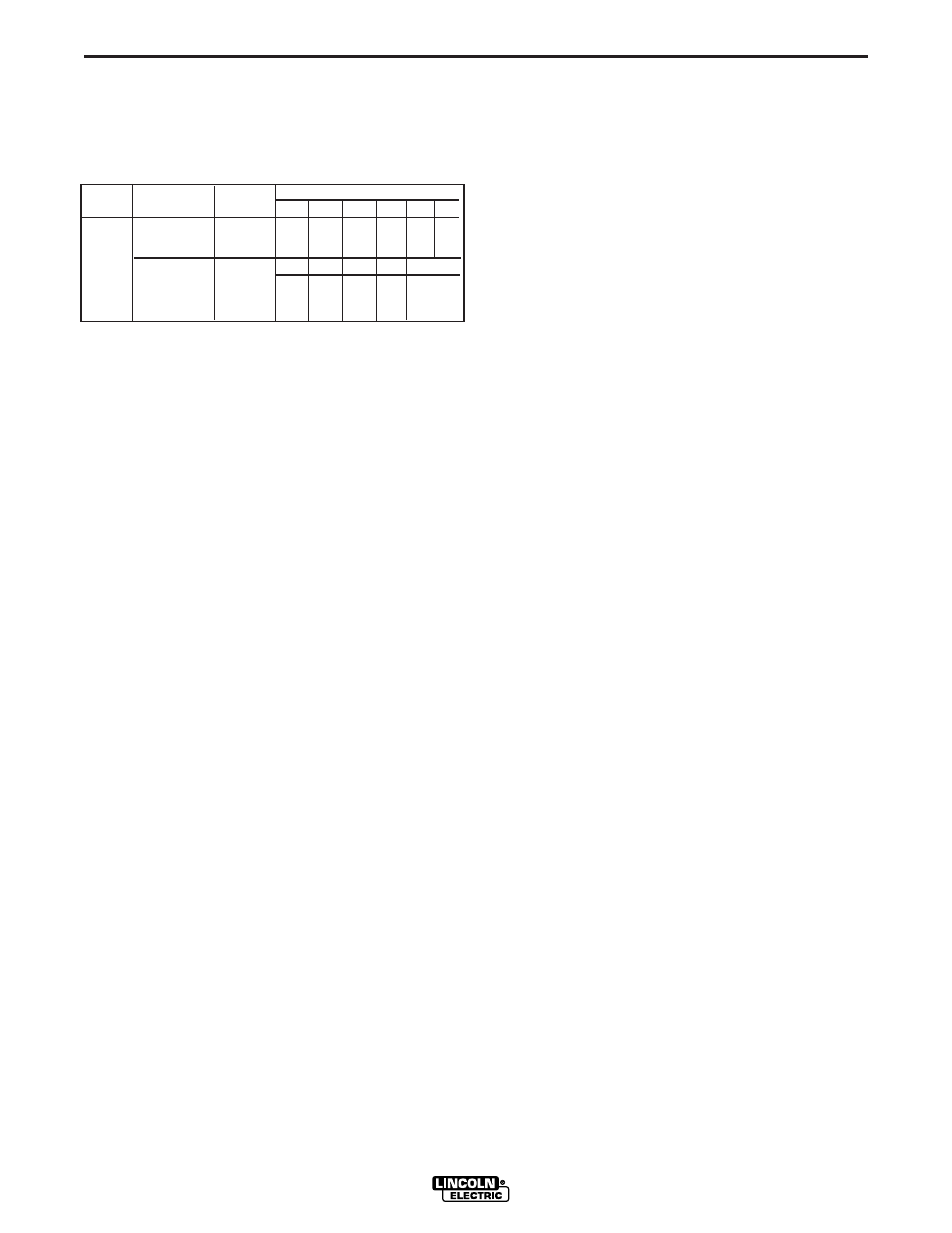

The Pro-MIG 135 is suitable for .035" aluminum wire

and .030" stainless wire. Refer to Table B.1 for recom-

mended procedure settings.

TABLE B.1

NOTE:

NR - Not Recommended

CHANGING MACHINE OVER TO

FEED OTHER WIRE SIZES

The Pro-MIG 135 is shipped from the factory ready to

feed .023”-.025” (0.6 mm) diameter wire. To operate

the Pro-MIG 135 with other sizes of wire, it is neces-

sary to change the contact tip and change the drive

roll over to other sizes. Refer to Changing the Contact

Tip and Changing the Drive Roll, in the MAINTE-

NANCE section, for specific information on these pro-

cedures.

WELDING WITH GMAW (MIG)

Shielding Gas

When using the GMAW process, obtain and install a

gas regulator and hose kit. If using CO2 a CO2

adapter is required, sold separately.

1. For CO2, open the cylinder very slowly. For argon-

mixed gas, open cylinder valve slowly a fraction of

a turn. When the cylinder pressure gauge pointer

stops moving, open the valve fully.

2. If using a regulator with an adjustable flow meter,

close the gun trigger and adjust the flow to give 15

–

20 cubic ft per hour (CFH) (7 – 10 I/min.) [use 20

–

25 CFH (10 – 12 I/min.) when welding out of

position or in a drafty location for CO2]. For argon

mixed gas, trigger to release gas pressure, and

adjust the flow to give 25 – 30 CFH (12 – 14

I/min.).

3. Keep the cylinder valve closed, except when using

the Pro-MIG 135. When finished welding:

a) Close the cylinder valve to stop gas flow.

b) Depress the gun trigger briefly to release the

pressure in the gas hose.

c) Turn off the Pro-MIG 135.

WELDING WITH FCAW (Innershield)

When using the FCAW process, the correct drive roll

and electrode polarity must be used. See Work Cable

Installation in INSTALLATION section for changing

the polarity.

Innershield welding kit K549-1 (for .035" / 0.9mm) is

also available.

OVERLOAD PROTECTION

Output Overload

The Pro-MIG 135 is equipped with a circuit breaker

and a thermostat which protects the machine from

damage if maximum output is exceeded. The circuit

breaker button will extend out when tripped. The cir-

cuit breaker must be manually reset.

Thermal Protection

The Pro-MIG 135 has a rated output duty cycle of

20%. If the duty cycle is exceeded, a thermal protector

will shut off the output until the machine cools to a

reasonable operating temperature. This is an auto-

matic function of the Pro-MIG 135 and does not

require user intervention. The fan continues to run

during cooling.

Electronic Wire Drive Motor Protection

The Pro-MIG 135 has built-in protection for wire drive

motor overload.

Pro-MIG 135

Shielding

Voltage/Wire Speed

Process Welding Wire Gas 22 ga 16 ga 12 ga 1/8

”

3/16

”

1/4

”

.035 Dia(0.9mm 100% Argon A-4.5 C-8.5 D-10

NR

NR

NR

4043 Aluminum

Wire

MIG DC+

16 ga 14 ga 12 ga 10 ga

.030 Dia 98% Argon/ A-3 C-6

D-7.5 D-7.5

308L Stainless 2% Oxygen

Steel Wire