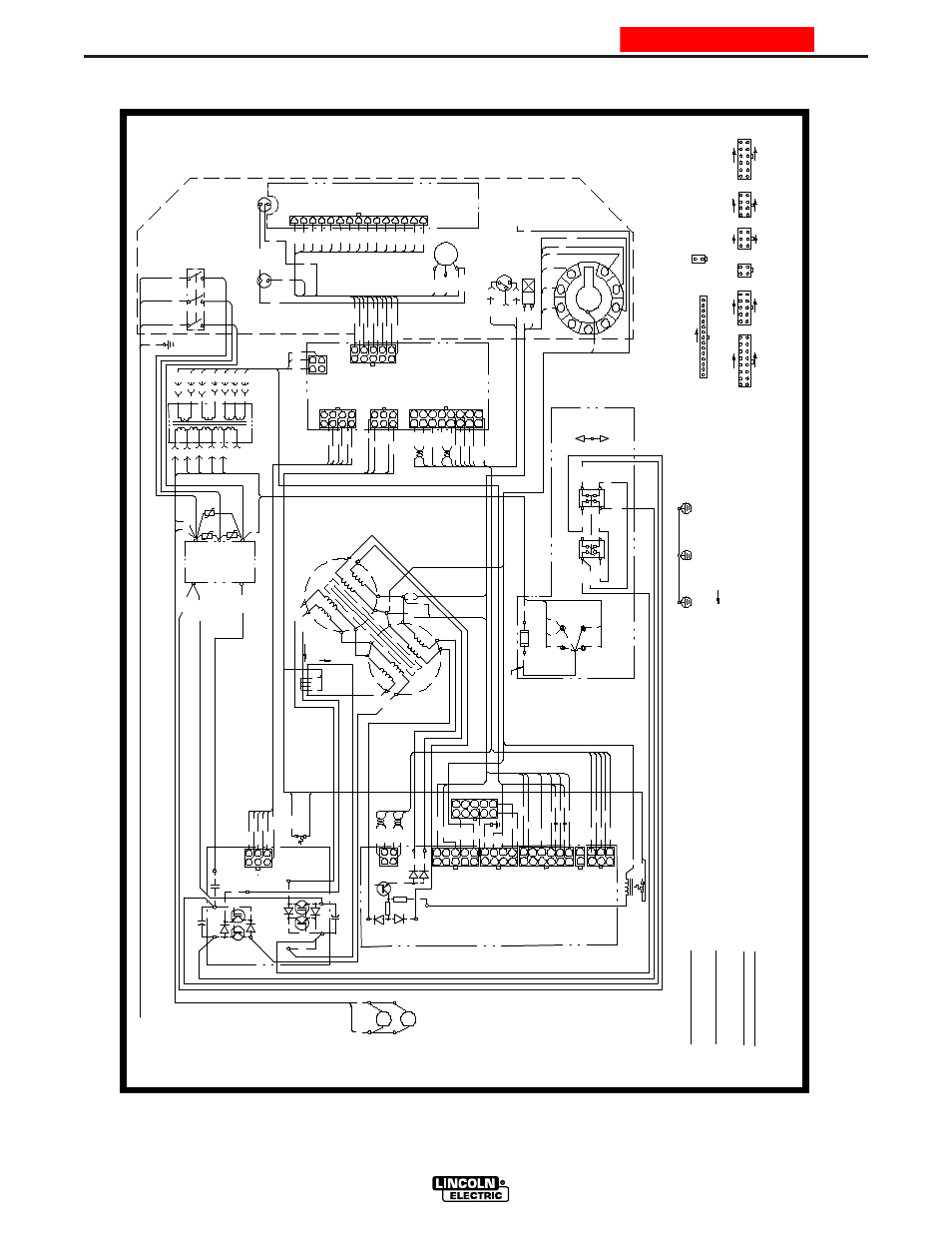

Diagrams, Enhanced diagram, Pro-cut 55 – Lincoln Electric IM637 PRO-CUT 55 User Manual

Page 34: Electrical symbo ls per e1537

F-4

DIAGRAMS

F-4

PRO-CUT 55

EL

EC

ELEC

xxxxxx

x

CONT

ROL

S4

PRIMARY

LEFT SI

D

E

OF

MA

C

H

IN

E

36

0

J3

3

J37

S2

R

ESE

T

J5,J22,J3

6

15

14

217

21

6

J3

5

223

J4,J1

0,

S3

PSI_SE

T

J1,J2

0,

J33

54

B

U

R

S1

V

W

R

POWER

W

53

8

12V

N

56

H1

R

N

51

2

24V

20

3A

20

6

C1

1200/450

POWER

4

1

5

2

6

3

50

3

T3

27

7A

22

1

400-

460

VAC

200-

ELECTRICAL SYMBO

LS PER E1537

RECON

NE

CT

L12066

12

3

4

13

4

6

1

5

4

1

8

7

6

12

N

E

18V

15

5

10

1

6

8

1

16

1

9

INPUT

WIRING DIAGRAM (CODES 11011, 11012, 11015 & 11016)

AUXILIARY TRA

NSFO

RME

R

J22

T2

4

H6

+

-

S

A

22

0-

23

0V

01/

2

6/

20

04

460

V

200

-

208

V

H4

38

0-

41

5V

BK

-O

UT

BK

-IN

6

W

R

21

9

R =

RED OR PI

NK

(VIEW

ED FRO

M CO

M

P

ONENT SIDE OF

BOARD)

W =

WHITE

CONNECTOR CAV

ITY NU

M

BERING

S

EQUENCE

G = GREE

N

B = BLACK OR G

RAY

COLOR CO

DE:

DISPLAY

W

ORK

36

4

36

9

2

2W

10K

4

CW

(M

A

X)

27

7

276

R1

R

W

Y

36

6

361

J20

J3

8

1

2

U = BLUE N = B

ROWN

Y =

YEL

LO

W

X4

0

X1

0

W

X2

0

X3

0

X3

X2

7

3

XFM

R

2

MAIN

T1

6

0.6A

+

D

SLOW BLOW

F

-

20

7

11

4

5

5

6

7

1

2

3

1

2

3

4

10

3

2

1

12

13

5

11 T

R

IGGE

R

12 GND

3 I

G

B

T

J3

2,

6 P

S

I S

W

IT

C

H

10

EL

EC

SO

L

9 AI

R

SO

L

CT

TS

TA

T

RE

LA

Y

++V

O

LT

P_

XF

MR

B

S

BASE

FR

-O

UT

PROTECTIVE BONDING CIR

CUIT

CASE FRONT

BK

-IN

I

BK

-O

UT

I

64

61

62

Y

22

1

22

3

27

5

277

27

6

275

30

2

215

21

4

213

21

2

20

2

210

218

206

217

216

20

3

20

7

20

3

J1

20

2

202

A

R

W

31

2

H5

J21

61

U

W

62

U

64

9

TP3

H1

5

TP2

TP1

H1

B

C

D1

INPUT BRIDGE

20

9

207

A

4

FR

ON

TO

FM

AC

HIN

E

1.

FOR MA

C

HINE

S SUPPLIED WI

TH INP

UT CABLE

FOR SINGLE PH

ASE INPUT: CON

NECT GRE

EN LEA

D TO GROUN

D PE

R NATION

AL ELECTRIC CO

DE.

CON

NE

CT BLACK & WHITE LEADS TO SUPPLY CIRC

UIT.

WRAP RE

D LEAD WITH TAPE TO PROVIDE 60

0V.

INS

ULATION.

FOR TH

RE

E PHA

SE INP

UT: CON

NE

CT GRE

EN LEAD TO GROU

N

D

PE

R

NATION

AL ELECTRIC CODE.

CON

NE

CT BLACK, R

ED & WHITE LEADS TO SUPPLY CIRC

UIT.

2.

FOR MA

C

H

INE

S NOT SUPPLIED WI

TH INP

UT CABLE

FOR SINGLE PH

ASE INPUT: GROUN

D MA

C

HINE PER NATION

AL AND LOCAL ELECTRI

CAL CODE

S.

CON

NE

CT TERMINALS U & W TO SUPPLY

CIRC

UIT.

FOR TH

RE

E PHA

SE INP

UT: GROU

N

D

MA

CHI

NE PE

R

NATION

AL AND LOCAL ELECTRICAL CO

DES.

CO

N

NECT TERMINALS U, V & W T

O

SUPPLY CIR

C

UIT.

THE INTE

R

C

HANGEA

BILI

TY OF A COMPLETE BOAR

D, THIS DIAGRA

M MAY NOT SHOW THE EXA

CT

COM

PONE

NTS OR

CIR

C

UITRY HAVI

NG A CO

MMO

N CO

DE N

U

MBE

R.

N.B. SINC

E COM

PONE

NTS OR

CIR

C

UITRY OF A PRINTE

D CI

RC

UIT BOARD MAY C

HANGE WITHOUT AFFECTING

CO

NNE

CTION S

HOWN IS FOR 44

0-46

0V OPERATION.

N.C. PLACE "A" LEAD ON APPROPRIATE CON

NE

CTION FOR IN

PUT VOLTAGE.

N.

D. C1 AND C2 CA

PA

CITORS ARE A M

ATC

HE

D SET.

J4

365

N.A.

J3

5

H1

H3

FAN

NOTES:

+15V

R

EAD

Y

L

E

D

27

7B

18V

18

V

J2

7,

8 EL

EC

SH

U

N

T (

TW

IST

P

R

)

N

4,

5

XF

ER

SH

U

N

T (

TW

IST

PR

)

G

RIG

H

T SI

D

E

OF

M

A

C

H

IN

E

J5

PER N.A

.

30

6

303

30

2

309

230

VAC

A

X4

20

3A

N.C.

S

E

MOTORS

W

401

X2

FAN

OUTPUT

PC BOAR

D

FAN

40

4

401

B2

1

L1

CHOKE

J4

0

J3

J40

AIR

11

S5

12

SOLENOI

D

13

PRESS

U

R

E

CONT

RO

L

21

5

21

0

21

4

21

9

21

3

218

21

2

1

4

277

A

306

9

14

15

6

16

7

8

50

3

209

20

5

50

1

RE

LA

Y

50

5

20

8

50

2

++

V

O

LT

50

6

P_

XF

MR

507

J10

201

204

207

A

20

2A

-

+

2

N

N

OUTPUT

11

,1

2 =

12

V

3,

8 W

O

R

K

5, 10 ELEC

TR

ODE

J3

8

1

NOZZL

E

X20

X40

5,

6 EL

EC SOL

3,

4 AI

R SOL

1,

7 TR

IG

G

E

R

PO

T

9

1

A

S

50

2

S

H3

S

H3

H2

S

FR-

IN

S

8

Y

Y

CUR

RE

NT

C2

1200/450

TRA

NSFO

R

MER

R W

X4

1

3

R

2

4

2

4

1

3

40

4

Y

H4

7

20

1

H3

2

5

1

}

B

LO

W

_PSI

L

E

D

PO

T W

IP

E

R

R

E

SET

GN

D

TH

E

R

M

A

L LE

D

SAF

ET

Y

L

E

D

P

SI SET

18V

6

3

H2

XF

E

R

XF

E

R

RE

AR

OF

MA

CH

IN

E

xxxxxxx

20

5

FR-

OU

T

FR-

IN

S

W

31

0

3

35

4

4

5

6

7

8

8

9

7

10

6

5

10

4

9

5

3

8

2

2

7

4

1

3

6

X1

50

5

50

1

506

4

507

J2,J

21

,

J3

7,J

39

20

8

20

4

H5

1

2

J39

21

1

RE

S

E

T LE

D

8

21

1

A

A

9

8

12

11

10

36

5

34

3

36

0

3

2

6

4

34

4

1

5

5

10

4

9

3

8

2

7

1

6

7

8

3

2

6

4

1

5

7

1

2

3

2

6

4

30

9

1

5

5

10

4

9

3

8

2

7

1

6

E

G

54

51

347

348

4

2

361

366

56

369

53

364

303

310

312

354

J3

6

2,

3 =

24V

4,

8 OK

TO

M

O

VE

J3

9

1,

2 T

R

IGGER

2 E

LEC SOL

3 T

R

IGGER

4 I

G

BT

53

56

J30

1 AI

R SOL

6 GND

22

3

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The specific diag

ram for a particular code is pasted inside

the machine on one of the enclosure panels. If the diagram is illegible, write to the Service Department for a replacement. G

ive the equipment code number.

Enhanced Diagram