Installation, High speed gear box, Warning – Lincoln Electric IM713 POWER WAVE 655R User Manual

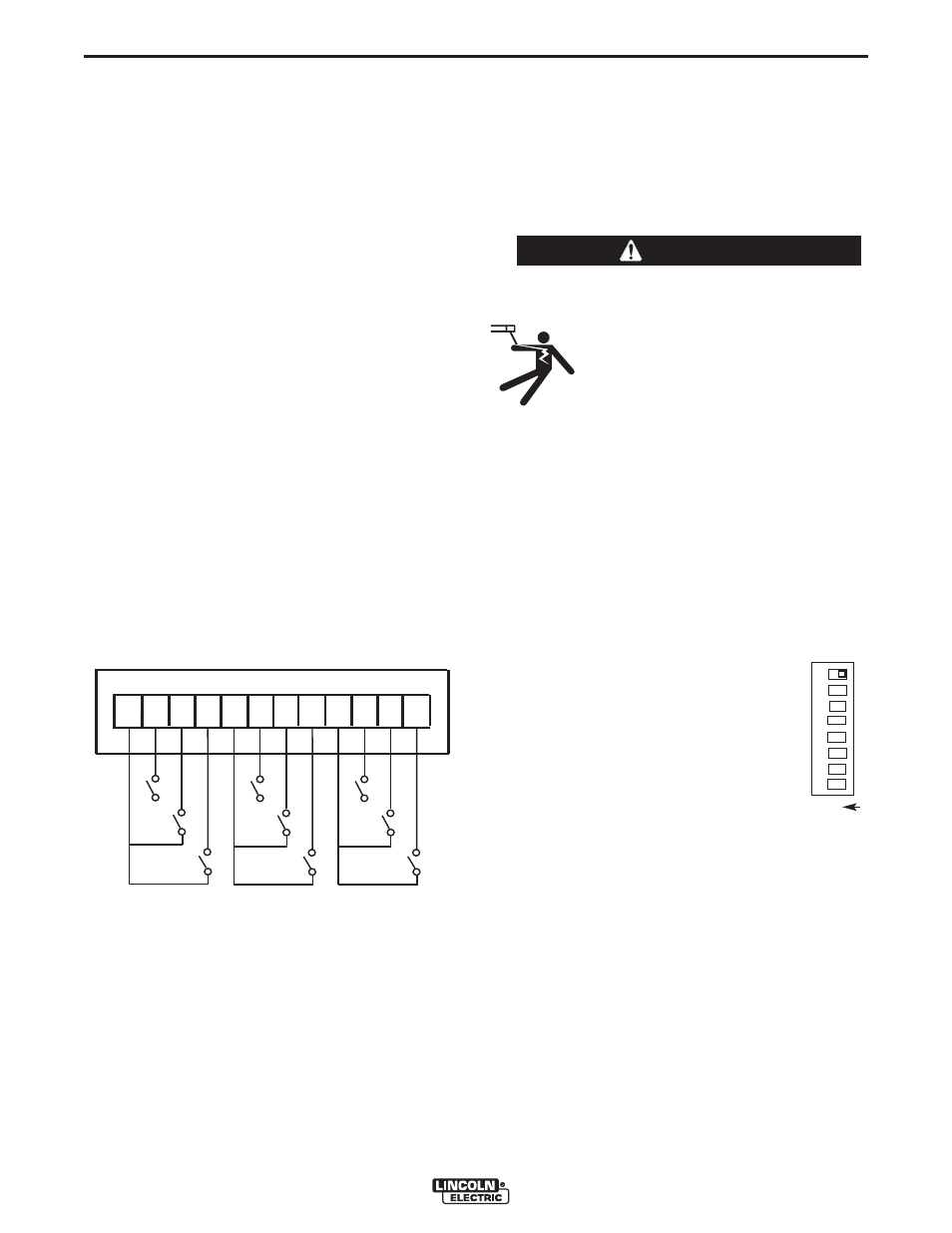

Page 15: External i/o connector, Figure a.5

HIGH SPEED GEAR BOX

Changing the ratio requires a gear change and a PC

board switch change. The Power Feed

®

Wire Feeders

are shipped with both high speed and a low speed

gears. As shipped from the factory, the low speed

(high torque) gear is installed on the feeder. To

change Gear ratio see Power Feed

®

10/R Instruction

Manual.

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts or

electrodes with your skin or wet

clothing.

• Insulate yourself from the work and

ground.

• Always wear dry insulating gloves.

------------------------------------------------------------------------

1. Set the High/Low switch code on Wire Drive PC

board as follows:

• Turn off power to the power source at the discon-

nect switch.

• Remove the front cover from the power source.

• The wire feed head board is on the right

side of the power source. Locate the 8-

position DIP switch and look for position

8 of the DIP switch.

• Using a pencil or other small object,

slide the switch right to the OFF posi-

tion, when the low speed gear is

installed. Conversely, slide the switch

left to the ON position when the high

speed gear is installed.

• Replace the cover and screws. The PC board will

“read” the switch at power up, automatically

adjusting all control parameters for the speed

range selected.

O

N

1

2

3

456

7

8

WARNING

A-8

INSTALLATION

POWER WAVE

®

655/R

A-8

EXTERNAL I/O CONNECTOR

The Power Wave

®

is equipped with a port for making

simple input signal connections. The port is divided

into three groups: Trigger group, Cold Inch Group and

Shutdown Group. Because the Power Wave

®

is a

ʻslaveʼ on the DeviceNet network, the Trigger and

Cold Inch Groups are disabled when the DeviceNet /

Gateway is active.

The shutdown group is always enabled. Shutdown 2

is used for signaling low flow in the water cooler.

Unused shutdowns must be jumpered. Machines from

the factory come with the shutdowns already

jumpered. (See Figure A.5)

D

E

F

1

2

3

4

5

6

7

8

9

10 11 12

G

H

I

A

B

C

+15

VDC f

or

T

rigger Group

T

rigger Input

Dual Procedure Input

4 Step Input

+15

VDC f

or Cold Inch Group

Cold Inch F

orw

ard

Cold Inch Re

v

erse

Gas Purge Input

+15 f

or shutdo

wn g

roup

Shutdo

wn1 input

Shutdo

wn2 input (W

ater F

ault)

Reser

v

ed f

or future use

FIGURE A.5